Fig. 1: Zones of a single-screw extruder. Fig. 2: Protein molten phase and swollen starch granules. Fig. 1 is a schematic view of a single-screw extruder with different zones. The first section is the feed zone, where the formula mix is added to the extruder. This zone is characterized by deep channel screws designed to convey.

.jpg)

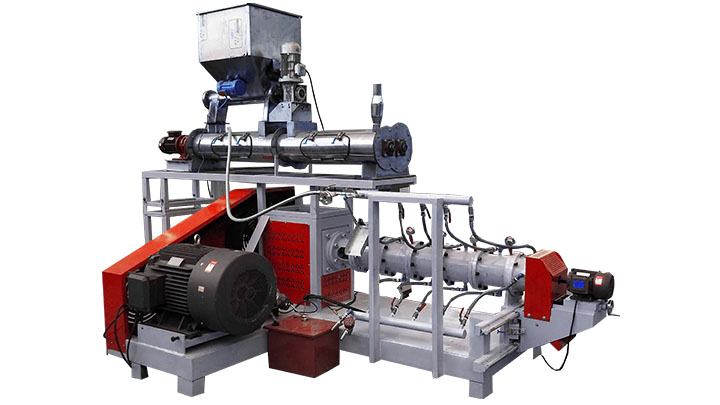

ANDRITZ single screw extruders represent state-of-the-art technology, ensuring high quality aqua feed at minimum operating costs. Extruder – EX1250. High capacity extrusion: 10-20 tph; High degree of processing flexibility; User-friendly design for operation and maintenance; Minimum downtime; Extruder – EX1021. High capacity: 2-12 tph

And increase the extrusion efficiency from 63.25 % to 72 %. Keywords: extrudates, extruder, evaluation, fish feed, floating and performance I. Introduction The extrusion process operates in a dynamic steady equilibrium where input variables are balanced with the output.

The superiority of our Fish Feed Pellet Extruder. 1. This fish feed-making machine, made from alloy steel, has a stable structure, lower noise, small occupation, and easy operation, all of which make it popular among the farmed fish industry. 2. For a dry-type fish feed-making machine, there is no need to add additional water to the machine, so

Aug 1, 2016 · Design and fabricated of a fish feed extruder with improved qualities and affordable cost, the design was carried out using engineering principles with due consideration to cost, ease of operation

Jul 14, 2023 · A minimal crumbling is provided at the following values of. the factors -. feed mixture moisture before e xtrusion is 32%, extrusion temperatur e is 132 °C, and pressure is. 0.4 MPa. In the

The aim of this project is to design and fabricate a fish feed extruder with improved qualities and affordable cost using locally sourced materials to aid the production of extruded feeds by local small scale farmers.The design was carried out using engineering principles with due consideration to cost, ease of operation, serviceability

The floating fish feed extruder allows for precise control over the pellet’s size, shape, density, and nutritional composition, ensuring that the fish receive a balanced and high-quality diet for optimal growth and health. This technology is crucial in the aquaculture industry, where efficiently producing nutritious and cost-effective fish

High production capacity: The extruder machine for fish feed has a production capacity ranging from a few hundred kilograms to thousands of kilograms per hour, which is suitable for farms of different sizes. Energy-saving design: Reduce energy consumption and operating costs by optimizing the power system and processing flow.

.jpg)

Dec 1, 2021 · The single s crew fish feed extruder developed was tested based. on the following performance variables. They include c onstant. feed moisture, constant feed rate, and constant screw speed. while

.jpg)

Die design –cutter assembly is one of the most im-portant sub-units of the aquafeed processing line as it determines the physical quality of the final product. - Micro-aquatic feeds often used as starters are products smaller than 2.0mm. Specific die design allows direct extrusion of mi-cro-aquatic feeds down to 0.5 mm. Products are

.jpg)

Aug 15, 2022 · Design, Fabrication and Performance Evaluation of a Single Screw Extruder for the Production of Floating Fish Feed August 2022 Journal of Scientific Research and Reports 28(10):1-10

state-of-the art technology, ensuring unique quality feed at minimum operating costs. The optimized extrusion concept for unmatched performance consists of controlled feeding of dry ingredients, optimum conditioning with steam and liquid addition, an even flow rate to the extruder, and high extrusion flexibility and controllability.

.jpg)

Fish Feed. Clextral extrusion systems efficiently produce high-energy feed with a precise balance of proteins, oils and carbohydrates, processed for optimum digestibility. Extruded feeds are produced to match fish feeding habits (floating, neutral buoyancy or sinking) to energize feeding and reduce waste. We offer an output range from 25 to

.jpg)

Introduction. As an upgrade of the DGP series, the LX series extruder uses high temperature, high pressure and shearing force to cause physical and chemical changes in the starch and protein in the feed through short-term high temperature and high pressure treatment, thereby improving the solubility and digestibility of the feed.