.jpg)

Animal Feed. Empowering Excellence in the Animal Feed Industry. Explore CME’S Pellet Mills & Hammermills. At Colorado Mill Equipment, our dedication to serving the animal feed industry isn’t just about producing machinery; it’s about providing the tools that enable you to meet the ever-evolving demands of your customers.

Step 1: Draft a feed milling business plan; Step 2: Choose a location; Step 3: Acquire the land; Step 4: Get the required approval and licenses to operate a feed mill; Step 5: Draw the feed mill architectural plans and have them approved; Step 6: Hire a professional for constructing your feed mill; Step 7: Purchase the machinery and equipment

.jpg)

New arrivals. , for the Feed Mill Process,fish Pelletting & Processing, Fertilizer, Seed & Grain, Industrial and related Industries, Please note that all Equipment descriptions, photos and documentations on this site supplied to us by the Owner of the equipment are to be used as a guideline only. A visit inspection will confirm the condition.

.jpg)

Sep 18, 2017 · Through product development, equipment manufacturing and engineering technology, Kemin is able to make substantial contributions to improving the profitability of feed manufacturing. The company has designed a customised program for feed milling customers called MillSmart. According to Kemin, the program increases feed mill profitably and

.jpg)

Animal Feed Processing Equipment. For nearly ninety years, Schutte Hammermill has been a pioneering force in the design and manufacturing of size reduction equipment, specifically tailored for the processing of feed and grain.

.jpg)

Jan 25, 2023 · The equipment using the largest amount of electricity in a feed mill can be broken down as follows: 40% pelleting; 26% milling; 9% mixing; 6% material handling; 19% other; 1. Pelleters. The pelleter is the biggest energy user in the feed mill, says Cooper. Not only does it use the most electricity but requires most of the gas as well.

.jpg)

PELLETING. The transformation of a soft, often dusty feed into a hard pellet is accomplished by compression, extrusion, and adhesion. The general process involves passing a feed mixture through a conditioning chamber where 4 to 6 percent water (usually as steam) may be added.

Our animal feed solutions help you produce top quality feed and to make economical use of your raw materials and energy. As a technology partner with long-lasting experience in the industry, we support you in every aspect of the production of reliable animal feed. Download brochure.

.jpg)

Dec 2, 2015 · In conclusion, the future of the feed industry truly lies in its ability to meet consumer demands for safety and sustainability, while increasing efficiency and productivity to feed nine billion people in 2050. Consolidation of the over 31,000 feed mills will continue, potentially reducing numbers by 50 percent in the next ten years.

When it comes to setting up your own mill you should be aware that they must adhere to strict sanitation standards in order to prevent disease outbreaks. Your state may also require you to obtain a license before starting operations. To set up a feed mill you will need to purchase equipment such as grinder mixers, augers, conveyors, bins, etc.

.jpg)

Apr 3, 2024 · Key Equipment for a Feed Mill Business. Essential Feed Mill Equipment. Considerations for Feed Mill Equipment. The Role of Automation in Feed Mills. Innovations in Feed Mill Technology. Factors to Consider in Feed Pellet Production Line. Perform Deep Market Research In Seconds. Optimize Your Livestock Business: Investing in Feed Mill Equipment.

Dec 14, 2011 · As an example, consider costs associated with pelleting when comparing commercial feed mills to integrated feed mills. It costs a commercial feed mill roughly $8 to $10 per ton to pellet. With an integrated feed mill, pelleting costs are approximately $3 to $4 per ton. Note the substantial difference between these two estimated costs.

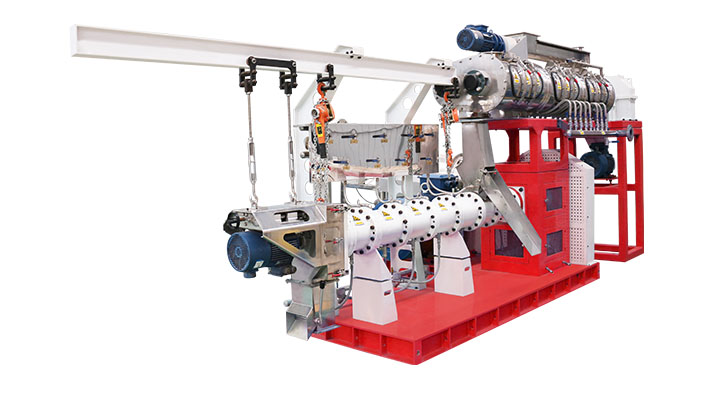

Expanded feeds. Flaking feeds. Floating fish feeds. We deliver Australia wide and our primary engineers are based in Australia, who can guide you through the planning of an upgrade or a complete turn-key project. Animal Feed Mill - We supply all range of animal feed mills capacity starting from 1 Ton/Hr up to 40 ton/Hr for laboratory feed mill