With over a half-century of experience in supplying feed mill equipment to the industry came a thorough knowledge of feed mill operations and optimization. Design & Integration. Baker-Rullman pioneered the modern bolt-together modular bin system used in feed mills today and continues the innovation with frequent improvements based on customer

In the Animal Feed Milling Industry different materials (cereals, coarse powders, fine powders, mash, bran, liquids and molasses) are milled, fed and weighed, and mixed together including additives to obtain the final product. WAMGROUP manufactures specialised equipment for handling, de-dusting, feeding, conveying, intercepting, mixing and bulk

With its constant efforts towards new and more effective products, the company entered into the feed machinery market and fabricated its first small 2 H.P. Hammer Mill in 1994. Within a short span of time, this organization has grown well and has more than 1500 installations all across the country as well as overseas which includes single

Welcome to Martindale Feed Mill. “The Quality Standard Since 1962”. Martindale Feed Mill is a full line feed mill based in Valley View, Texas, that serves the North Texas and Oklahoma area with quality feed products for your cattle, livestock and horses. Known for our quality premium feeds and cattle cubes, you can trust Martindale Feed

The FFM Berhad Group diversified into animal feed milling in 1981 at Port Klang with an initial capacity of 10,000 mt of feed per annum. Today, the FFM Group owns five feed mills in Malaysia, strategically located in Prai, Pulau Indah, Pasir Gudang, Kota Kinabalu and Kuching with a total production capacity of 67,200 mt/month.

VIDEO: Formulation software can reduce feed’s footprint. Jackie Roembke | April 12, 2022. New technologies provide nutritionists the ability to reduce the environmental impact of feed, animal production. As companies strive []

Feed Mill Design Services Dwight Kinzer, dba Process Equipment & Design LLC specializes in the Process Flow Diagrams, Master Planning, 3D & 2D CAD Layout, and Program Management of Animal Feed Production Plants. dwight dot kinzer @ gmail dot com 620-951-4211

Innovating plant & mill operations for over 50 years. If you’re looking for innovation in plant automation and someone who will always have your back, you’ve found it. Repete designs and delivers automated control system solutions worldwide. More than 1,400 systems are currently in operation. We’ve supported some of them since before

Animal Feed Granulation with a High Speed Mixer. While the traditional approach to animal feed production has served the industry for a long time, our proprietary approach to the granulation of Mono-Calcium Phosphate (MCP), Di-Calcium Phosphate (DCP), and De-Fluorinated Phosphate (DFP) yields an improved product with greater uniformity and

Find 1 listings related to Franklin Feed Mill in Plymouth on YP.com. See reviews, photos, directions, phone numbers and more for Franklin Feed Mill locations in Plymouth, WI.

Working With Us. Give us a call today at 1-815-625-0852, toll-free in the USA at 1-800-257-7214, or email us at sci@sterlingcontrols.com to see what kind of custom engineered solution can be offered by Sterling Systems & Controls to meet your business and process objectives!

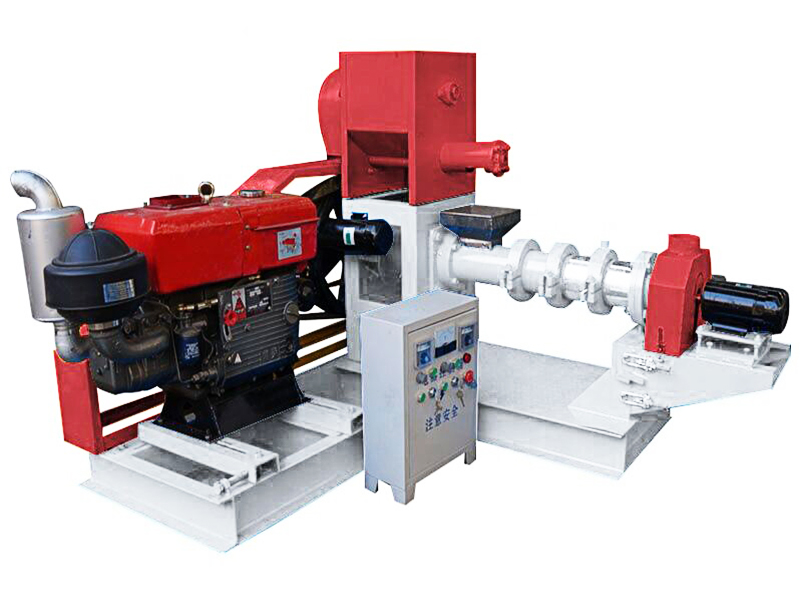

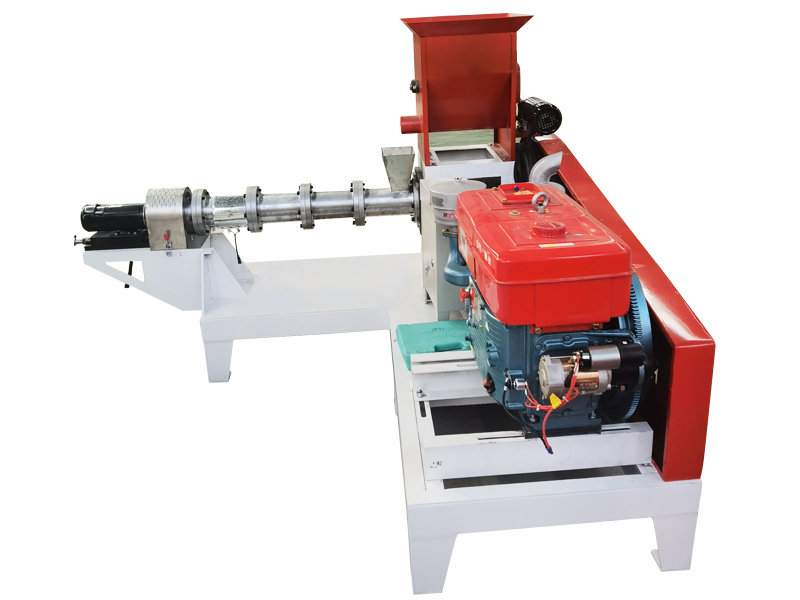

Small Scale Animal Feed Pellet Production Line. This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the

Feed Mill automation can simplify operation and improve efficiency of cost and throughput. Sterling Systems & Controls, Inc. custom designs and manufactures the highest quality automation control systems for virtually any Feed Mill process or a complete facility.

wheat mill G8. corn barley bean. Production capacity: 15,000 kg/h - 30,000 kg/h. The Rivakka Greenmaker G8 is a tractor-driven roller mill for fresh or dry grain. The mill 's serrated-edged, hardened rollers effciently pull grain inside and carefully crush even the smalled grain.

Apr 10, 2017 · A successful, effective, and low-maintenance dust collection system is achievable. Follow these best practices to reduce long-term costs and maximize your dust collection system: 1. Proper system design. The method used to determine proper air flow and distribution throughout the system must be the “Balanced-by-Design” method.