⑩ Counter-flow type fish feed cooler ★ Scope of application Mainly used in the process of cooling granular feeds in large and middle sizes feed mills, to easily transport, store, and save, the SKLN contraflow cooler cools granules with a temperature of 60-80 degrees and moisture of 13-15 % from the front dryer down to a little higher than room temperate and moisture 12-13%.

The full automatic feed production line is a sophisticated assembly of machinery designed to create animal feed on a large scale. This category encompasses a variety of machines that work in unison to convert raw materials into finished feed suitable for a range of animals, from farmed fish to livestock. The integration of automation within

.jpg)

The floating fish feed plant is a turn-key project for Iran client contracted by RICHI Machinery. This is a compound 1.5-2T/H extruding fish feed production line and a 5-6T/H animal feed production line. It is mainly used to produce fish feed pellets and shrimp feed pellets. Capacity: 1.5-2t/h floating fish feed and 5-6t/h shrimp feed.

A: In India’s ever-growing aquaculture sector, employing an automatic fish feed machine offers several advantages: 1. Efficiency: Automatic fish feed making machine in India significantly speed up the feed production process compared to manual methods, allowing for more production in less time. 2.

.jpg)

200-225 Kg/Hr Automatic Floting Fish Feed Plant. ₹ 9,60,000 Get Latest Price. Capacity: 200 kg/hr. we, “Fabon Engineering Private Limited are a reputed organization involved in Manufacture and Exporter a wide array of Organic Fertilizer, Sieving Machine, Vibro Separator, Cattle Feed Pellet Machine , Cattle Feed.

.jpg)

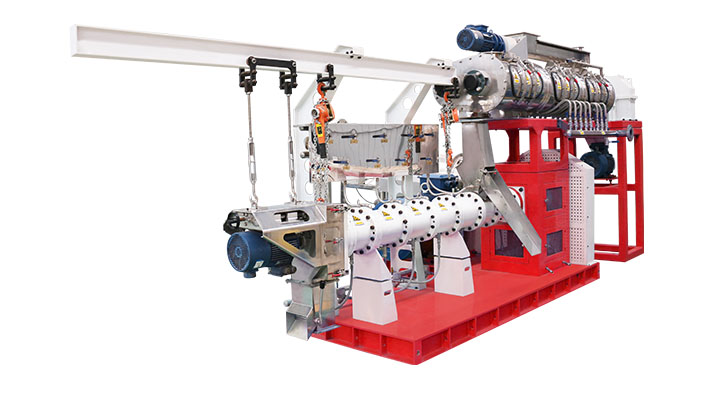

Industrial Fish Feed Production Line is made of food grade stainless steel and whole line is fully continuous and automatic. Fish Feed Making Machine has the characteristics of high automation, easy operation, stable performance, cheap price, easy maintenance and wide material selection.

8-10 t/h animal feed production line project design —— RICHI MACHINERY —— Annual production capacity: 20,000 tons (3,000 t/a concentrated pig feed production line, 17,000 t/a chicken concentrate supplementary feed) Project area: 3000 square meters; Working system: The project has 14 employees.

.jpg)

The price of 1 ton floating fish feed making line is usually 30,000-150,000 USD. According to your needs, we can also provide custom design services. Pls send me a proforma incoice include transport price for 2-3t/h floating fish feed production line. The 2-3t/h floating fish feed line cost is USD 80,000-500,000.

.jpg)

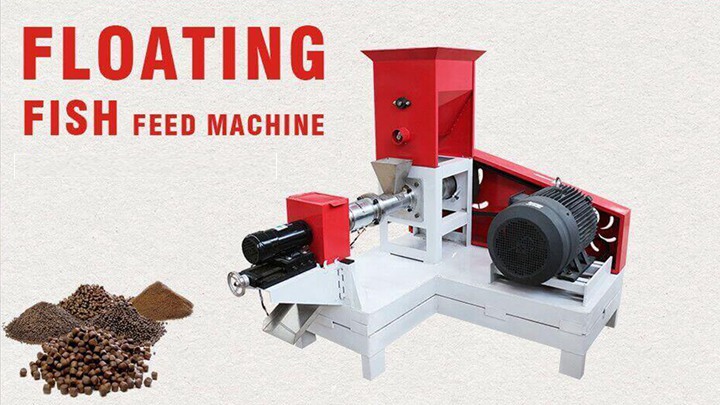

100 Kg Fish Feed Extruder Machine ₹ 2,50,000. Get Quote. Floating Fish Feed Plant, 100 Kg/hr ₹ 4,48,000. Get Quote. Watch related videos. Sinking fish feed making machine, 100-120 kg per hr. Sinking and floating fish feed processing line, 1000 kg per Floating fish feed extruder, 50 kg per hr.

The pet food production line, fully automatic for cat and dog food, includes raw material processing, extrusion, drying, seasoning, and control systems. It offers high stability, automation, and control over extrudate expansion, affecting texture. Made from stainless steel, this dog food line features a reasonable design, alloy steel screws

.jpg)

The automatic floating fish feed mill processing plant project covers an area of 3333m2, about 5 acres, with a construction area of 3200m2. It is planned to employ 15 employees, all of whom will not be accommodated in the floating fish feed mill plant. Working 8 hours a day, 300 working days a year, the annual sales revenue is expected to be 50 million yuan (7850000USD), and the profit will be

01 1.5-2T/H Floating Fish Feed Line Price. 80000-400,000 USD. 02 Application. 1.5-2T/H floating fish feed processing line can process floating fish feed, pet feed, and can also be upgraded to a combined feed production line, and can process shrimp feed, special feed, livestock and poultry feed, premix and other products at the same time.

Jul 24, 2023 · The mechanical equipment process of the fully automatic feed production line is composed of cleaning, crushing, batching, mixing, granulating, packaging and other systems. Each system has a number of equipment and devices. The front and rear systems and the equipment in the front and rear processes are almost all connected mechanically.

Average score: 3.0/5 (2 votes) Compare up to 10 products. Find your fish processing line easily amongst the 15 products from the leading brands (Cantek, Cabinplant, HIDRONER, ) on DirectIndustry, the industry specialist for your professional purchases.

.jpg)

Feed pellet line/plant is also called feed pellet production line. A complete feed mill plant or feed pellet line generally includes silos for raw material storage, raw material receiving system, first batching system, mixing system, second batching, crushing system, pelletizing system, cooling system and bagging system.