.jpg)

Moreover, you can change extrusion degree to influence floating time. The fish pellet made by the machine can float on water more than 24 hours. Gelatinization degree can reach 90%. Brand Name:Loyal. Model Number:PFE-65-1 PFE-70-1 PFE-85-1 PFE-90-1 Place of Origin:Shandong, China.

.jpg)

The cost of a Floating Fish Feed Producing Machine can vary widely depending on its size, capabilities, and complexity. Most of the price of Floating Fish Feed Producing Machine ranges from US $ 1400 to $ 120000 per Set.

Prices in Bengaluru range from 60,000 to 60,00,000 INR for various types, including Micro Floating Fish Feed Extruder, Fish Meal Plant Machinery, and more. Take advantage of exclusive deals on Tradeindia when ordering in bulk. Contact the sellers today to get the best offers. All Results Bengaluru Erode Chennai Secunderabad Kolhapur Baramati

Production Line Advantages. Features of floating fish feed Production Line: 1) Design: Developed by 3D software, analog simulation, and it has been tested by a computer automatically, in order to ensure the accuracy of the design requirements. 2) Concept: Modular function, humanized menu system, and various applications are always our pursuits.

The Automatic Fish Feed Making Machine is a technological marvel that simplifies the complex process of fish feed production. Its advantages of efficiency, versatility, and cost-effectiveness make it an invaluable asset for any fish farm. Make a calculated decision, and invest in an automatic fish feed pelletizer machine to revolutionize your

Bread Crumbs Manufacturing Line Commercial Bread Crumbs Making Machine. US $ 8,000-35,000 / Piece FOB. MOQ: 1 Piece. Since 2013. Main Products. Fish Food Machine, Pet Food Machine, Floating Fish Food Pellet Machine, Dog Food Extruder, Floating Fish Feed Machine, Floatiung Catfish Food Extruder, Corn Flakes Processing Line, Snacks Food

This floating fish feed extruder machine is a single screw wet pellet machine needing steam for pellet production, suited for large plants. We offer another type for home and small farm use. Depending on your requirements, you can choose how many volumes of finished floating fish feed pellets to produce. Wet fish feed extruders produce premium aqua See full list on pelletizermill.com When raw material enters the feeder, it cooks and sterilizes under high pressure and temperature without external heating. Starch and fibers expand during curing. Under pressure-sealed conditions, a die shapes the material into pellets. The automatic machine’s screw rotation and front cutter then produce small, puffed balls at normal temperature an... See full list on pelletizermill.com The floating fish food extruder is widely used for aquatic feed, known for its versatility and low noise. The high temperature and pressure process kills salmonella and bacteria in the material, making particles easier to digest and absorb. We offer different molds for various feed pellet diameters (0.9-15mm) and shapes, meeting diverse needs. The ... See full list on pelletizermill.com Corn, corn, soybean, rice:contains about 10-14% protein, and also contains vitamins B1, B2, B6 and a small amount of enzymes. Straw powder, grass powder, rice bran, wheat bran: contain fiber, prevent various fish diseases Mustard Cake: Mix up to 40% cake in fish feed. But don’t use more than 20% dry cookies. Mustard cakes contain 30-32% protein. Co... See full list on pelletizermill.com ①Choose a plane position based on the production flow and workshop layout. For steel frame units, elevate the fish feed extruder. Position the cooler inlet 500~800mm below the extruder outlet, allowing room for a crusher if using high-starch mixtures. After discharge, material falls into the cooler via a hood or hopper, suiting various puffing proc... See full list on pelletizermill.com Oil change time 1) You must regularly replace the main bearing seat’s oil with new oil. Change the oil for the first time after about 2 months, then every other year. During oil changes, empty all old oil and clean the oil tank with compressed air. 2) For other bearing parts, grease once every 48 hours of operation. 3) Frequently lubricate the chain transmission mechanism on the conditioner. (for wet type fish feed extruder machines) 4) Regularly replace the oil in the conditioner’s reducer with new oil.The... Other maintenance precautions 1) Weekly, clean the feeding bin’s upper gate to avoid feed delays from blockages. 2) Remove residual material from the feeder barrel walls weekly. 3) Weekly, clean where the feeder outlet and conditioner inlet connect. 4) Clean the conditioner’s water and steam nozzles weekly for smooth liquid addition. 5) Weekly, clean the bypass and remove residual material at the extrusion assembly’s feed port. Electrical maintenance 1) Re-lock and check the primary wire in the main motor’s electronic control. (Note: After 15 days of commissioning, please re-lock the primary circuit in the electrical control cabinet) 2) Check for motor overload, thermal protection activation, main circuit short-circuit, air break protection activation, or motor damage during a sudden shutdown. See full list on pelletizermill.com

Floating Fish Feed Extruder Machine 3-4T/H. Floating Fish Feed Pellet Making Machine 4-5T/H. Floating Fish Feed Pellet Mill 6-7T/H. Fish Feed Pellet Extruder 8-10T/H. Floating Fish Pellet Machine For Sale 10-12T/H. Sinking Fish Feed Machine. Menu Toggle. Fish Feed Processing Line. Sinking Fish Feed Pellet Mill 0.6-1.2T/H.

Apr 10, 2024 · Function: Fully automatic production of floating fish feed Output: 2 tons per hour Shipping method: Shipping Main equipment: mixer, feed extruder, cooler, dryer, seasoning machine, packaging machine. Order Date: 2024/2/12 This customer runs a fish feed factory, and later wants to expand the business into pet feed.

.jpg)

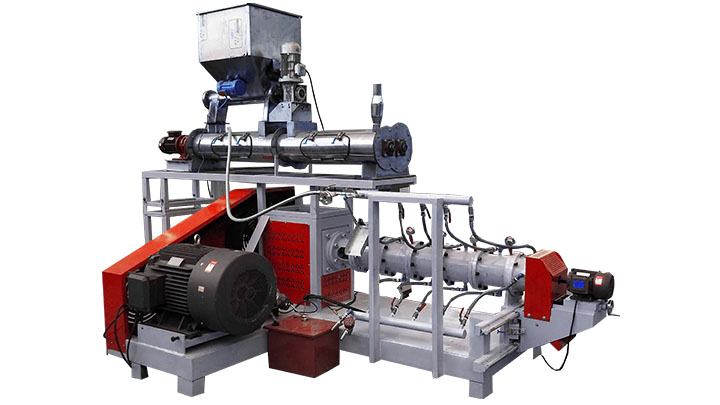

Detailed introduction of the Animal feed floating fish feed pellet machine 1. floating fish feed pellet machine , also known as fish feed extruder, is used to process various kinds of grains into high-grade aquatic feed pellets for fish, crab, catfish, shrimps, etc. 2. This fish feed machine has gained popularity in fish farmers. 3.

.jpg)

The RCPH120*2 extruder machine for fish feed is mainly used for the 1.5-2t/h production and processing of various floating aquatic feeds. The new type conditioner can soften material fibers, improve gelatinization degree, reduce power consumption and increase production capacity. Main power: 75kw.

.jpg)

0.5Hp,2800 Rpm 3 Phase. Pelleting Dia. 1.8mm / 2mm 3mm / 4mm 5mm / 6mm. Country of Origin. Made in India. shri lakshmi info services is known for their quality products in all our India and out of India also. Fish feed manufacturing machine is also called fish feed extruder and fish feed extruder.

Feed Pellet Making Machine - Pellet Mills Latest Price, Enlight Engineering. Potent Pellet Mill, 20-35 kg per hr. ₹ 60,000 Get Latest Price. Capacity: 20-35 kg per hr. Motor Power: 3 hp. Material: Mild Steel. Dimensions (LxWxH): 800 x 470 x 920 mm. Weight: 30 kg. Automation Grade: Automatic.

Video. Dry Type Pet Food Machine Floating Fish Feed Extruding Machine. FOB Price: US $3,000-5,000 / set. Min. Order: 1 set. Contact Now. Video. Dgp80 Fish Feed Extruder Pet Food Making Machine Small Fish Pellet Machine. FOB Price: US $3,000-5,000 / set. Min. Order: 1 set.

Consider After-sales Services when you buy fish feed extruder machine in Nigeria. Sometimes, a slightly higher on how to buy fish feed extruder machine in Nigeria can include extended warranties, maintenance services, or training sessions. These add-ons can save significant costs in the long run. 5. Spare Parts Availability.