The SERVODAY PELLETBOX revolutionizes pellet production in Cabo Verde with its innovative, containerized design, offering maximum portability and efficiency. Ideal for localized manufacturing, it reduces transportation costs by bringing production closer to biomass sources.

Small poultry feed mill machinery for Cape Verde 1-2 ton per hour easy to operate poultry feed mill for commercial purpose. The installation of this 1-2 ton per hour Get Price +

Apr 5, 2022 · Drax’s investment of over $100 million in the new Demopolis pellet plant brings new jobs and economic opportunities to Alabama with 350 people employed during construction and 60 new direct jobs. The plant will produce 360,000 tonnes of sustainable biomass pellets a year from sawmill residues such as sawdust, chips and shavings.

Whether softwood or hardwood, particle board or MDF, both pellet mill systems focus on qualityfish pellets produced at the lowest cost. We have turnkey systems that take small chips, shavings, or CNC dust collector waste and transform them into quality, dust-freefish pellets with high BTU-value, low ash, and low fines.

.jpg)

Pellet Mill 400 Pellet Mill 400 TheLimaHansen MPEL Plate mill is a multipurpose pelleting press, that provides an excellent product at a reasonable price, both in capital cost and in maintenance.The simplified flat die system is longer wearing and has a lower replacement cost than the ring die pellet mills common in South Africa.

.jpg)

Cape Verde (/ ˈ v ɜːr d (i)/ ⓘ, VURD(-ee)) or Cabo Verde (/ ˌ k ɑː b oʊ ˈ v ɜːr d eɪ / ⓘ KAH-boh VUR-day, / ˌ k æ b oʊ-/ KAB-oh -, local Portuguese: [ˈkabu ˈveɾdɨ]), officially the Republic of Cabo Verde, is an archipelago and island country of West Africa in the central Atlantic Ocean, consisting of ten volcanic islands with a combined land area of about 4,033 square

.jpg)

In 2022, Cape Verde's electricity consumption was predominantly reliant on fossil fuels, which accounted for almost 84% of the total electricity generated. The remaining 16% of the electricity came from low-carbon sources, with wind energy being the major contributor at nearly 14%, and solar energy providing a small share of about 2%.

.jpg)

Boiler fuel: 40 kg/ ton ~ 200 Rs/ Ton: ElectricityFeed Mill: Approx. 25 units/ ton ~ 200 Rs/ Ton: Electricity fixed charges + 8 units per ton for utilities like boiler , silos, office , submersible etc.

SZLH Series Pellet Mill (V4/V6) Distinguished pelleting stability. Unique double-timing belt driving and cooling system for motors output same torque simultaneously, sectional ring die clamper for fixing ring die onto rotor firmly, widened supporting area of main shaft as well as wearing reduction designed working parts, are all enabling long-time stable production.

.jpg)

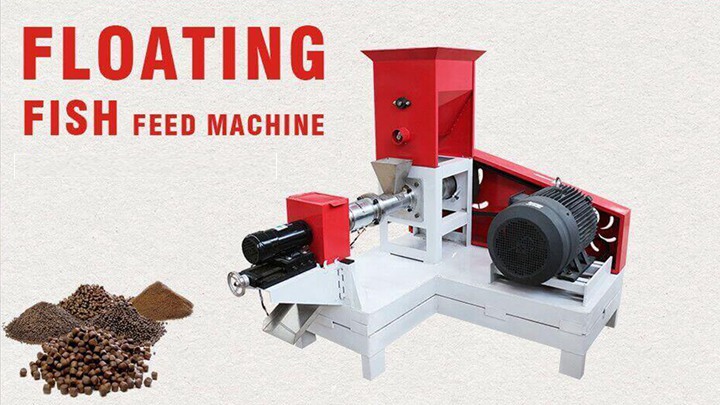

Thefish pellet mill price varies significantly based on the machine features, capacity, and the brand. On average, a small scale mill can cost anywhere from $1,000 to $3,000, while commercial grade mills can exceed $10,000.

.jpg)

The Pellet Mill is classified under our comprehensivefish Pellet Mill range.Purchasing afish pellet mill wholesale allows for significant cost savings, bulk quantities, and customized solutions. Wholesale orders often come with discounts, prompt shipping, and additional customer support.

Our pellet mills are built to the highest possible standards and designed to make your job easier, safer, and more efficient—and deliver you the best possible pellet. With robust reliability and ease of operation, your CPM pellet mill is backed by the best service and support teams in the animal feed, oilseed, andfish pellet maker industries.

.jpg)

Our range of Pelletizing Machines are ideal for creating livestock / animal feed by converting finely ground mash feed / bush feed into dense, nutritious pellets. Different Models: 125 Model 50/100 Kg/Hour

Our small, but industrial grade pellet mills effortlessly produce pellets from shredded paper and cardboard. Watch the video to see our 30hp pellet mill creating 340kg (750lbs) of premium paper pellets per hour; ideal for burning.

.jpg)

ANDRITZ Feed & Biofuel Technologies offer a range of well-proven pellet mills – ensuring highly efficient feed pelleting. Today’s demands for high-quality animal feed requires advanced pelleting equipment.