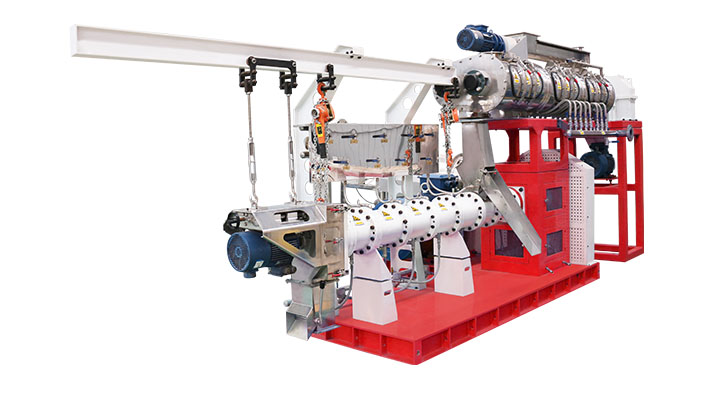

Sep 4, 2024 · Comparison of the characteristics between single-screw extruders and twin-screw extruders Single-Screw Extruder: Twin-Screw Extruder: In summary, the choice between a single-screw extruder and a twin-screw extruder depends on factors such as the specific application, material characteristics, required mixing capabilities, throughput rates, and budget constraints. Single-screw extruders are

Jan 31, 2024 · PVC Twin Screw Extruders: A 3-Minute Guide – This guide provides an overview of PVC twin screw extruders, which is a specific application of double screw extruder machines. It’s from Twin Screw, another manufacturer. Source

Leading the way in extrusion technology, we offer unparalleled expertise, quality and value. Established in 1983, Century Extrusion offers twin screw extruder parts and highly engineered twin screw extrusion systems covering different levels of extruders, from entry level to high level specifications for various customer requirements, as well

Mar 26, 2024 · Discover the different types of twin screw extruders, including co-rotating, counter-rotating models, etc. Whether in plastics, food processing, or pharmaceuticals, understanding these extruders is essential for maximizing manufacturing efficiency.

Jul 21, 2024 · A: In process engineering, a twin screw extruder is a kind of extrusion machine that is used primarily to mix and compound raw materials. It consists of two screws within a barrel which rotate either in the same direction (co-rotating) or in opposite directions (counter-rotating) for processing different materials.

EMD-55C conical type twin screw extruder, the screw diameter is 55/113mm, and the output around 60-120 kg/hr (depends on profile size and material). PVC counter rotating twin extruder available in sizes of EMD-65, EMD-90 and EMD-130 for profile and compounding , output ranges from 100 to 1500 kgs/hr.

.jpg)

Brand Story TwinScrew, empowers the twin-screw extrusion technology. In the era which relied on technological import, the initial drive of “doing it right” successfully pushes TWINSCREW forward, as well as it pushes forward the competitive edges offered by the Taiwanese extruder industry on the market.

.jpg)

Aug 20, 2023 · Single screw extruders are generally lower cost and are suitable for some simple extrusion processes, but may be limited in handling some complex plastic materials. Twin-screw extruders are slightly more expensive due to their greater processing power and adaptability.

.jpg)

Nov 30, 2023 · Jieya is a professional twin screw extruder machine manufacturer. Founded in 2004, the company is located in China. It has been consistently focusing on the R&D and manufacturing of various models of co-rotating twin screw extruders and highly efficient single screw extruders.

.jpg)

Bio Extruder The Best Bio Extruder Supplier from China Jieya is a leading wholesaler of Bio Extruders from China, offering top-quality machinery at unbeatable wholesale prices. Our Bio Extruders are built with the latest technology, ensuring precise and efficient extrusion processes.

.jpg)

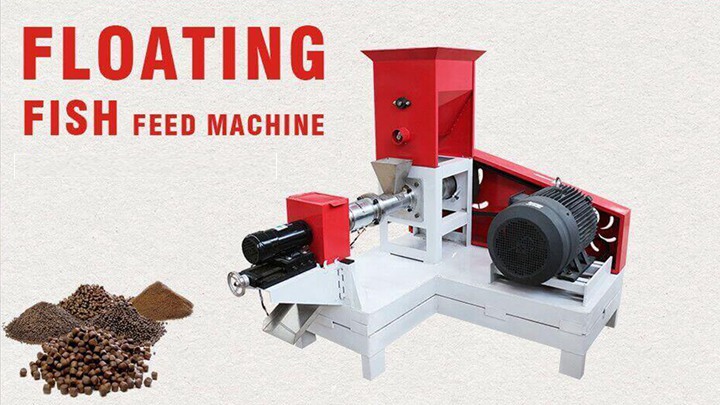

small scale Koi/Carp food extruder in Ghana-Fishfeedextruders small Koi/Carp extruded feed machine in Zambia Koi/Carp feed machine for the startup-Fish Feed Making Machines 4.Pellet size from diameter 0.9mm-15mm just by changing the mould. 5 Email: lima37@limamachinery-LimaTel: 8619337889051 Home Products Feed crushing machine

Simple, safe and precise monitoring thanks to the new and powerful PLC with 15 or 21 inch capacitive multitouch panoramic screen. Twin screw extruders and compounding machines are born from Bausano technological experience and the research of highly productive solutions.

.jpg)

The ZSK twin screw extruder gives you a processing plant featuring maximum throughput rates, gentle handling of the product, optimum economy and highest reliability.

Jan 20, 2024 · Items Single Screw Twin Screw; Screw Length-to-diameter Ratio (L/D) comparatively small: comparatively long: Screw Cross-section Thread Shape: Rectangular

Jun 21, 2024 · Extruder screws and barrels have witnessed substantial technological growth over the years. In the beginning, they were only meant for simple duties like rubber extrusion, but these parts have changed to handle the sophistication of contemporary polymer processing.