FEED PELLETIZER MACHINEFREE SHIPPING UNTIL NOV.11PANOORIN MO DITOhttps://youtu.be/UshoaRYX8uYPara sa mga alaga: ????Manok ????Baboy ???? Kambing ????Baka ???? Isda

The animal feed pellet mill is mainly driven by the rotation of the die plate to drive the rotation of the built-in pressing roller to quickly squeeze corn, soybean meal, grass fodder, green fodder, etc. into pellets. Feed pellets processed by the commercial animal feed pellet machine can usually be used to feed cattle, sheep, chickens, pigs

Categories ...

Most of animal feed pelletizing machine purchased from the market are suitable to produce feed pellets for livestock, poultry and fish. As for detailed livestock feed production process , poultry feed manufacturing steps and fish feed processing technology , you should contact the manufacturer to confirm all the details before placing the order.

1. How many bags of feed for 100 broilers? How many bags of feed for 100 broilers for 6 weeks? A broiler would consume an average of 4.25 kg from day old to the end of the 6th week. So, 100 broilers would consume (4.25 X 100) = 425 kg or 17 bags of feed for 6 weeks. A bag is assumed to contain 25kg of feed. 2.

Commonly, a poultry manure pellet machine is an integral part of the fertilizer granulation line. And we, as a manufacturer of fertilizer making equipment, offer 4 hot types of poultry litter pellet machines, namely poultry flat die granulator, disc granulator, rotary drum granulator and new type stirring granulator.

Feed pellet mill is widely used by people who breed chicken, rabbit, cow, sheep, cattle, pig, and so on. The raw material can be corn/maize, alfalfa, wheat b

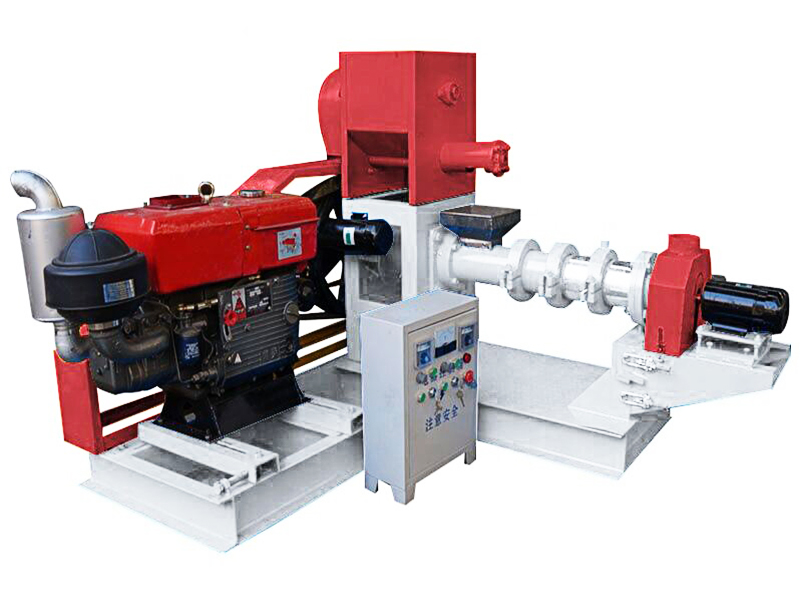

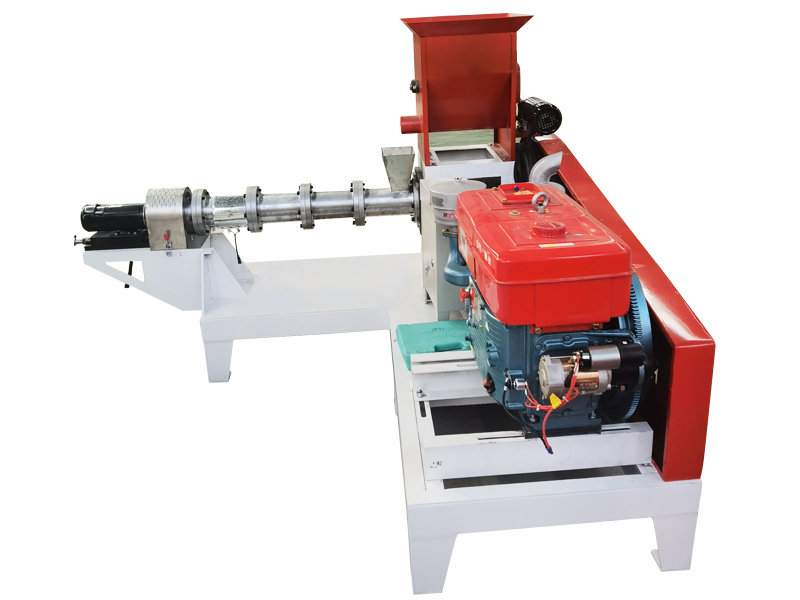

1. Powered by both diesel engine ,gasoline and motor,PTO driven. 2. Direct Connection of motor shaft and belt drive. 3. Can run smoothly with few noises. 4. poultry pellet making machine can equipped wheel,move around. 5. Machine can be used for making feed pellet,also makefish pellets.

Broiler Animal Food Pellet Machine Feed Pelletizer Machine For Animal Feeds , Find Complete Details about Broiler Animal Food Pellet Machine Feed Pelletizer Machine For Animal Feeds,Pelletizer Machine For Animal Feeds,Broiler Feed Machine,Animal Food Pellet Machine from Feed Processing Machines Supplier or Manufacturer-Henan Lima Machinery Manufacture Co., Ltd.

The Flat Die Pelletizer comes in various capacities depending on your intended level of production-100-150 kg per hour (3.5-4.2 KW) 200-250 kg per hour (6.0-7.5 KW) Uses/benefits: This feed pellet machine is equipped with screw feeder controlled by FC inverter with permanent magnet to removing iron impurities.

A feed pellet machine primarily gets used by people who engage in feed pellet manufacture and production or breed animals and need to feed them. The pelletized fodder can get used as a feedstuff for geese, rabbits, cows, pigs, chickens, sheep, pigs, cattle, and so on to consume. The pellets get preferred instead of some other fodder.

It is a feed processing machine that uses corn, soybean meal, straw, grass, rice husk, etc. as raw materials, and directly presses the raw materials into pellets after crushing the raw materials. Phone/Whatsapp : +86-15238391768 Email : sales@gcfertilizergranulator.com

The feed pelletizer in this small feed pellets production line has two types: ZLSP300B and ZLSP400B. The feed pellet mill machine presses feed mesh (like oil seeds meal, bone powders and corns, etc) to form pellets with uniform size (the same diameter and length). The feed pelletizer is a kind of flat die pellet mill and a good choice for

Product Description Home Use Small Poultry Forage Pellet Maker Livestock Fodder Pellet Mill Flat Die Pig Cattle Fish Feed Pelletizer Product Description IntroductionPM Series Flat Die Feed Pellet Machine is the main machine of making granular fodder,it can be used

I. Double-shaft Efficient Mixing Machine. 1. Extensively used for mixing powders, granules, flakes, blocks etc materials in feed, food, chemical industry, fertilizer industry and etc. 2. Highly mixing speed and short mixing cycle with 30-120s per batch of material. 3. High homogeneous degree, CV ≤5% and no material segregation.