Aug 01, 2021 · Any disturbance in steady-state consumption will affect intestinal-tract emptying and, consequently, sanitary dressing at the processing plant. Again, that large body of scientific research cited above has shown a broiler with steady-state feed consumption and full access to water will have an empty crop about 4 hours after feed withdrawal.

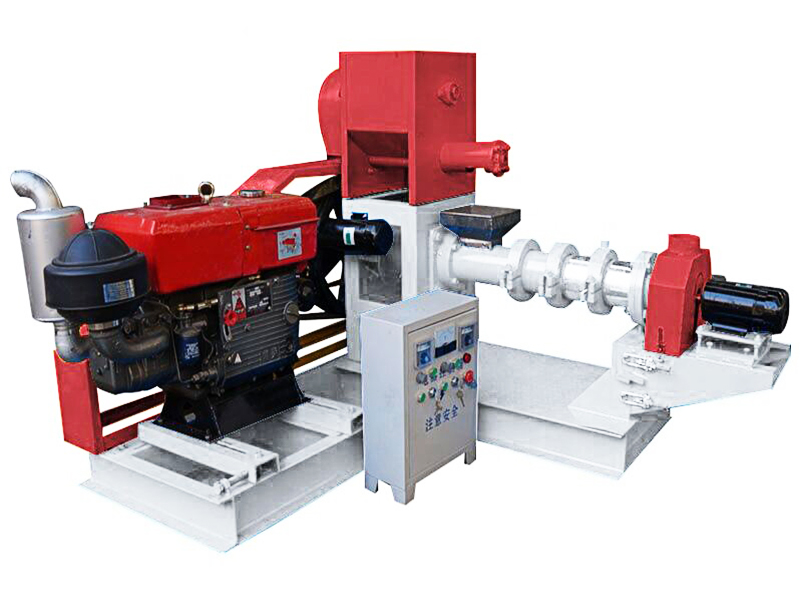

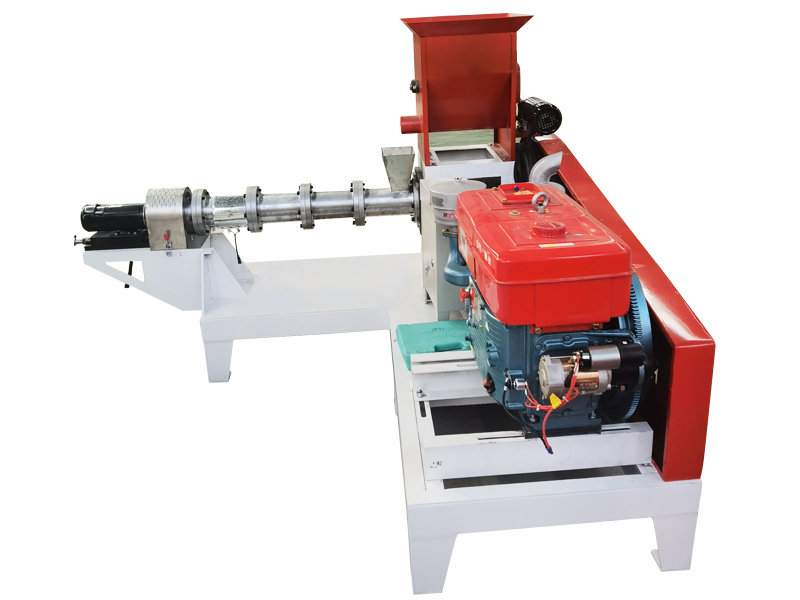

Setup Small Scale Broiler Feed Processing Plant. Our small broiler feed pellet mill can also be used to set up a small scale feed processing plant for poultry feed pellet production by adding other necessary auxiliary equipment, which allows relatively low setup cost and less energy consumption compared to large animal feed factory project.

Herpasa is building a new, complete plant for the processing of high-protein animal by-products. Once completed, the processing plant will have a storage capacity of 550Tn of flour, with an automatic weighing, mixing, and distribution system on a structure over 25m high. The processing of animal meal consists of several phases: reception of the

poultry feed production line is a complete feed pellet production plant processing feed like chicken feed, duck feed, bird feed, hen feed, broiler feed poultry feed processing plant for sale is used for hen feed and broiler feed production, it has small production output and large production capacity. the poultry feed production line for sale can produce chicken feed pellet, bird feed, duck feed and so on.

Oct 19, 2018 - If you are a beginner and need any help on starting your poultry feed processing business, here are some tips to help you make the best customized feed mill business plan and set up your own poultry feed plant step by step.

Young and finisher broilers require about 67g of feed daily. Broiler Feed Production Process Design. There are various feed production processes that manufacturers use. They include cold processing, hot processing, popping, pelletization, and extrusion processing. Of the processes, feed extrusion processing is the most advanced to increase productivity.

Poultry Feed Mill Plant. Capacity: 1-100T/H. Feed Pellet Size: 2-12mm. Feed Pellet Forming Rate: >90%. Application: poultry, livestock, ruminant,cattle, sheep, pig, goat, etc. Starting a poultry feed processing plant has always been a profitable business in many countries. Poultry feed plant is specialized in producing duck feed, goose feed

Poultry feed in some economies and marketplace is delivered in what is commonly known as a Gunny bag (or Jute Bag). These bags are made of hessian, burlap or crocus (sisal) plant fibre material. They are rugged, durable, strong and can be used for many applications. Poultry feed is just one.

Sep 08, 2015 · Broiler processing utilizes many equipment and machinery. The processing operations basically include slaughtering, scalding, de-feathering, eviscerating, washing, chilling and packaging/labelling. The number of birds to be processed per hour determines the processing equipment type employed, which largely depends on investment fund capacity hence, processing 50 – 100 birds per day may utilize only manual operation, processing of 200 – 1000 birds per day may utilize both manual and

If you are a beginner and need any help on starting your poultry feed processing business, welcome to get in touch with us! We are glade to help you on how to make the best customized feed mill business plan and how to set up a poultry feed plant step by step.

Apr 25, 2018 · Basic broiler processing equipment for small-medium scale is therefore identified below; Slaughtering Cones are funnel-shaped equipment made of stainless steel used for killing birds. It is designed to prevent the birds from flapping its wings or backing out during slaughtering and used to recover blood during bleeding.

Company Website: https://www.abcmach.comApplication: making feed pellets for feeding geese, duck, chicken, rabbit, sheep, cattle, pig, fish and other poultry

15TPH poultry feed plant project. This is a 10TPH poultry feed plant project we built for client in domestic. It consists of whole pellet production section from crushing to packing. 5TPH cattle feed plant. It is a 5 ton per hour cattle feed plant project in Chile, mainly used for manufacturing pellets for cattle breed.

7. Get the architectural plan and start constructing the plant. You will need to get the architectural plan and start building the required structures. This is a very important step because it will determine how your chicken processing plant business will look like. You can also hire an architect to do this for you.

Broiler starter diet. This diet usually contains 21-22% crude protein and 3000 Kcal/kg energy. This is fed for the first 10 days of life. Thereafter, the broiler chicks have a commensurate additional growth response. Broiler grower diet. This diet usually contains 19-20% crude protein and 3050 Kcal/kg energy.