Jul 21, 2020 · Our ring die feed pellet machine is a type of feed machinery for commercial purpose, belonging to the industrial pellet mill. The basic function of a ring die feed pellet mill is to produce high quality pelleted feeds for chicken, cattle, pigs, horse, duck etc. in large scale feed pellet plant.

This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the fine powder can mix with the wheat bran, bone

Oct 26, 2021 · Twelve male buffalo calves (Live weight 98.44±1.44 kg) divided in to three equal groups were fed iso-nitrogenous and iso-caloric complete feed pellets containing 25, 35 or 45% paddy straw ad lib

The animal feed pellet mill is mainly driven by the rotation of the die plate to drive the rotation of the built-in pressing roller to quickly squeeze corn, soybean meal, grass fodder, green fodder, etc. into pellets. Feed pellets processed by the commercial animal feed pellet machine can usually be used to feed cattle, sheep, chickens, pigs

Usa Pellet Mill offer you a wide stock of pellet mills, hammer mills, extruders, presses and many others solutions for your farm. USA Pellet Mill +1 (786) 918 3634 | info@usapelletmill.com

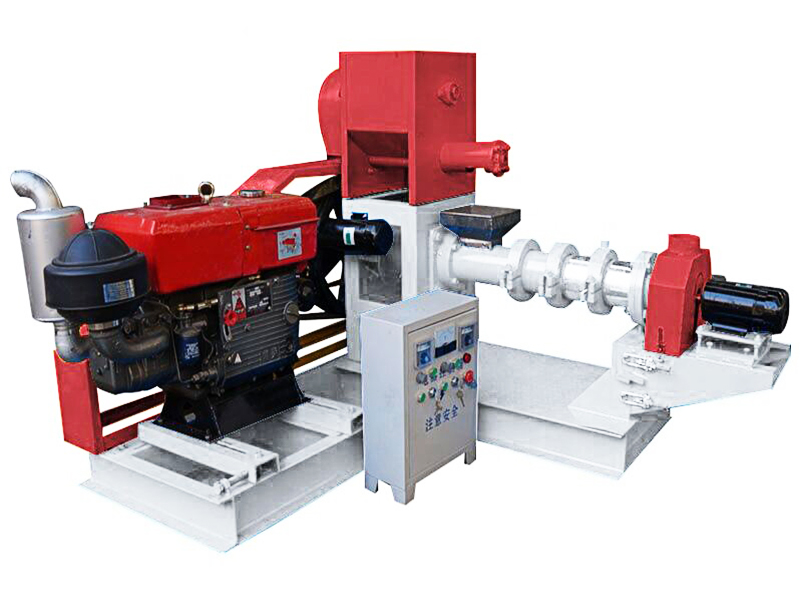

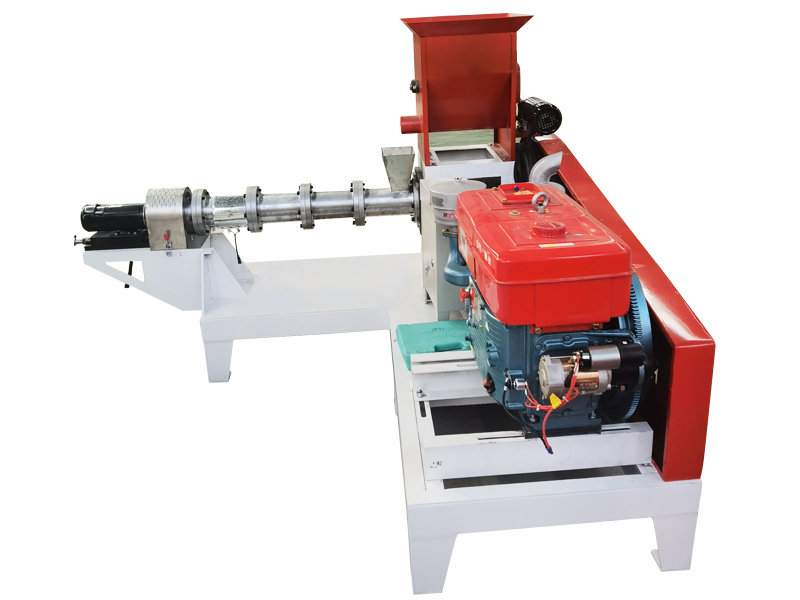

Feed Pelleting Machine. The Feed Pelletizing Machine is recommended for producing feed pellets, especially for fish feed. It is used to convert feeds in mash form into smooth, strong pellets of 2mm, 4mm, 6mm or 8mm depending on your need. The machine is simple in design and lightweight; and it is well recommended for small scale production of

Feed pellet line/plant is also called feed pellet production line. A complete feed mill plant or feed pellet line generally includes silos for raw material storage, raw material receiving system, first batching system, mixing system, second batching, crushing system, pelletizing system, cooling system and bagging system.

Feed & Pellet Mills - Colorado Mill Equipment. Colorado Mill Equipment is an innovative company dedicated to providing high quality pelletizing equipment to meet the needs of a global industry. We are equipped to run pelletizing tests on a wide variety of products, refurbish equipment, stock spare parts, and ship machinery internationally.

Tips of Making Pellets with Gasoline Pellet Mill Each time before making biomass pellets with this gasoline pellet mill, the machine needs warming up by oil mixture repeated for about 5 minutes. When the temperature reaches 80-100℃, the feed pellet press can make good pellets smoothly.

Pellet Mills for Feed and Grain Read more; Buffalo, NY 14206. 1-800-447-4634 ... A member of the Bengal Machine Family of Brands. Bengal Machine | Schutte ...

STLP300 for Mini Feed pellet Mill Plant (600~800kg/h) To start with; STLP 300 is a complete set of poultry / cattle feed making machine that utilizes a power of 45.7 kW, handles a feedstock of 600kg/hour to 800kg /hour on average (best choice for mini feed pellet manufacturing production).

As a professional feed pelleting machinery manufacturer and supplier, Lima Feed Machinery not only offers the single fish feed extruder machine, floating fish feed making machine, animal feed pellet machine, poultry feed production line for sale, but also provides the complete solution of setting up floating/sinking fish feed production lime, poultry feed production lines(50~10000kg/h).Lima

Oct 20, 2021 · Feed pellet plant is also called feed pellet production line. A complete feed pellet production line generally includes silos for raw material storage, raw material receiving system, first batching system, mixing system, second batching, crushing system, pelletizing system, cooling system, and bagging system.

Feb 01, 2021 · The developed feed pelleting machine consists of the die plate, die shaft, pelleting chamber, press rolls, clearance adjustment mechanism, hopper, V-belt and pulley drive mechanism, electric motor

Pellet making machine is designed to make pellets from biomass powdered material. The finished biomass pellet is a great substitute forfish, raw coal, fossil fuel, liquefied gas. With high thermal value and renewability, it is widely used in city heating system, hot water supply, industry fuel, etc. It is a high promising and high-value