Feed Production Output: 600~1000kg/h. Application: Start local business or built small factory of cattle feed or poultry feed manufacturing. Equipment Cost: The cost of this set of cattle feed pellet mill is $10,000~$25,000. (To offer the best project plan, we customize the feed pellet plant according to each clients' situation and requirments.

CAPTAINS GROUP is here to help valued customers in Bangladesh who want to plan, design, build and maintain all types of feed machinery systems. Generally, there are three types of feed distribution required for building a complete feed plant. These are - Fish, Poultry, and Cattle feed. Again, there are individual feed plants like the Poultry

Setting Up Cattle Feed Manufacturing Plant. Setting up a feed manufacturing plant can be a profitable business. This is especially true these days where there are lots of cattle farms established and are in need of supply of feeds for their cattle. Though setting up cattle feed manufacturing plant can be a very profitable business, it is important for you to know some information on how to actualize your dream business.

Sheep & Cattle Feed Mill Plant Photo Display The feed mill plant unit includes equipment of grinding, mixing, pelletizing and cooling. The bagging machine is also available to be included if you need. It is suitable for small and medium sized farms and feed mills to use.

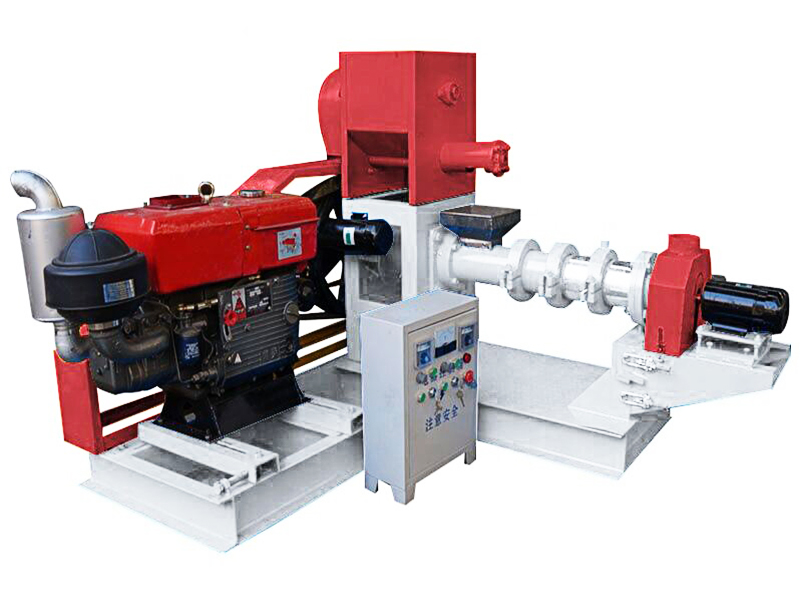

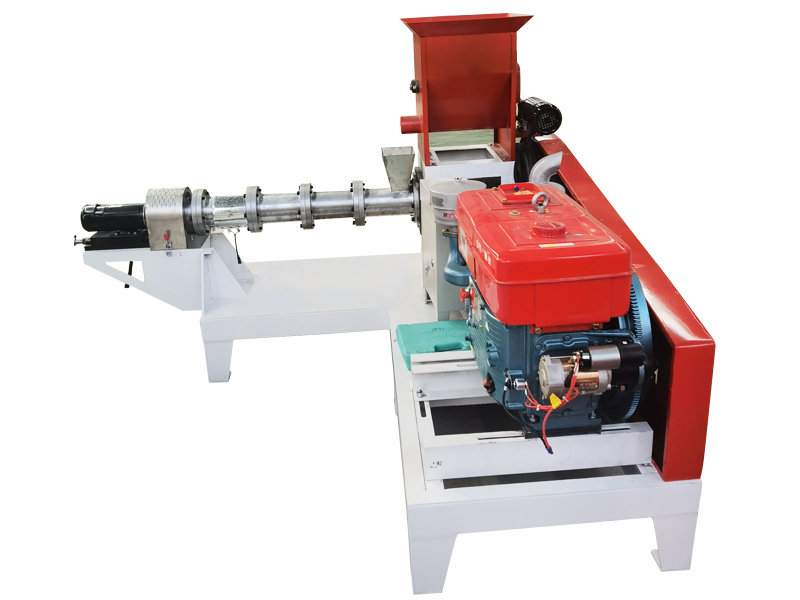

Small Cattle Feed Plant Layout Design. The small cattle feed pellet plant refers to a complete animal feed pellet mill that adopts flat die small feed pellet machine or ring die feed pellet machine with corresponding capacity and other auxiliary equipment, including raw materials grinder, mixer, feeder, belt conveyor, cooling machine, packaging machine and other equipment.

Jun 09, 2021 · Molasses. Calcium carbonate. Vitamin mixture. You need to make sure that you provide quality feed to sustain in this business for the long run. Also, know that every different type of feed demands a different mixing formula that you have to know. Hire a feed specialist to cater to this need. 5.

Aug 07, 2020 · Feed milling business is a growth enterprise in Nigeria. The Country feed mills produce feed for mostly poultry (chicken, turkey, ducks, guinea fouls, and quails, among other birds). Other classes

May 25, 2021 · Feed Mill Project Report – Profit in Feed Mill Business in India Profitability = Sales – Cost of Production = Rs. 14,00,000 – Rs. 11,72,000 = 2,28,000. Profit Margin in Electronic Shop in India: Investment, License, Project Report, and Business Plan

Apr 01, 2013 · Biblis plant, Herzogenbuchsee. The Biblis plant was constructed in 2001-02 and was energy-efficient from the start. A multi-stage grinding system using two-pass crushing mills and vertical-rotor hammer mills reduced the energy requirement by about 30 percent in comparison to a direct grinding system.

The Cattle feed manufacturing plant is suitable for the feed pellets production with different size for different growth periods or species, capacity from 500kgph to 20tph, different designs are available according to your requirements. A complete cattle feed manufacturing plant includes feed hammer mill, feed mixing machine, ring die feed

How to start a cattle feed processing plant can be divided into the following six steps: 1. Cattle feed formula and processing technology selection 2. Selection of cattle feed processing equipment 3. Layout and construction of cattle feed processing plant 4. Purchase and install cattle feed processing equipment 5.

Home sh.shuanghe@gmail.com 2021-10-12T02:04:26+00:00. Double Crane Machinery is a leading manufacturer & supplier of turnkey project solutions for poultry feed mill plant, animal feed processing plant, aqua feed plant, cat litter production line etc. As a professional feed mill plant manufacturer, supplier and exporter.

Constructing of feed mills to produce livestock feed – $10,000; Other start-up expenses (POS Machines, utilities, signage, business cards and stationeries) – $3,000; Purchase of truck for use in operation – $50,000; Purchase of furniture and devices (computers, printers, photocopiers) for administrative section – $3,000

This Livestock feed plant suit for the production of various livestock feed pellets such as cattle, pig, sheep, camel, etc, also suit for poultry feed. Pellet size ranges from 1.5-12mmm, capacity from 1tph to 20tph, which is built for small and medium scale animal feed factories. A complete livestock feed plant includes feed hammer mill, feed

Location counts a lot when starting a livestock feed mill business. In selecting the right location for your feed milling plant, you’ll need to consider areas with significant agrarian activity. In other words, part of the criteria should include areas with a significant level of agricultural activity.