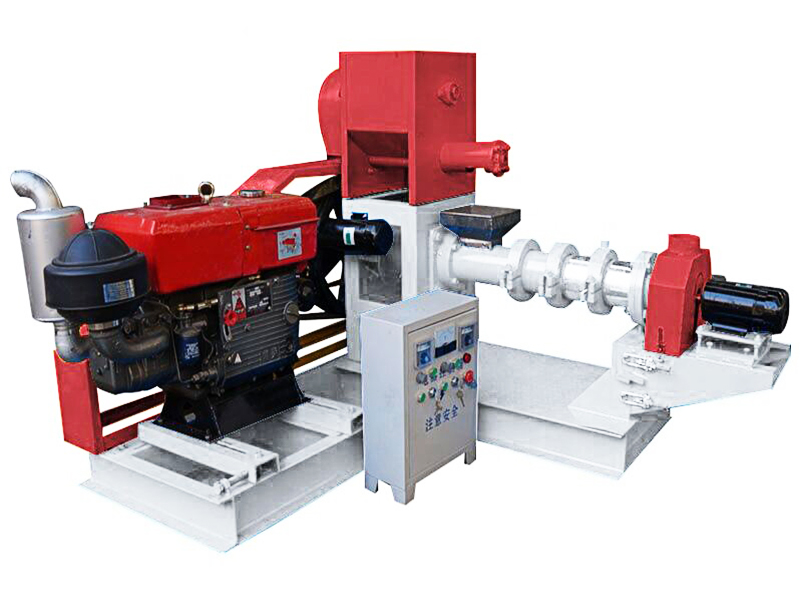

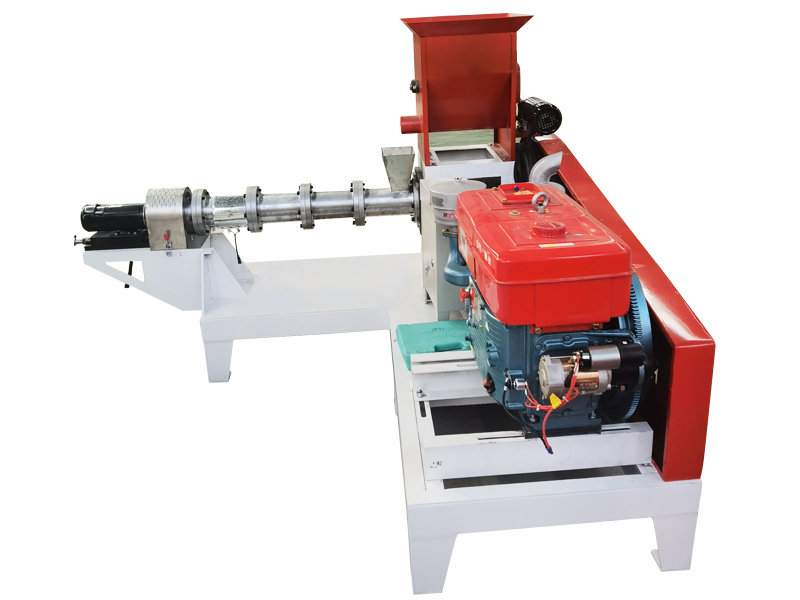

The poultry chicken feed production line is a complete set of equipment specially used for making poultry feed pellets. The production capacity of this poultry feed processing plant varies from 1 ton per hour to 10 tons per hour. The poultry feed processing line generally includes the following processes: raw material receiving and cleaning

Company Website: https://www.abcmach.comApplication: making feed pellets for feeding geese, duck, chicken, rabbit, sheep, cattle, pig, fish and other poultry

Jul 10, 2017 · This $200 million two-in-one poultry feed mill is officially the nation's largest start-up feedmill and has a production capacity of 25,000 tons per week. This mill was built due to the growing demand for poultry in the U.S. and supports three chicken processing plants in nearby Dothan, Union Springs and Jack, AL.

Cattle and Chicken Feed Mill Plant Setup in Uzbekistan [Project Report] This animal feed processing plant, ordered by a customer from Uzbekistan, was designed to produce cattle feed pellets and poultry feed pellets. The capacity is up to 4 tons per day. Our engineers have rich experiences in overseas installation and commissioning.

If you are planning to start your own chicken feed manufacturing business and need complete set of poultry feed pellet mill or mash feed processing equipment,Lima Machinery is surely your first choice! We offer tailor-made feed production business plan to ensure the success of your company.

A chicken pellet making machine can be used to make pellets for cattle feed, pig feed, chicken feed, horse feed, duck feed, fish feed and even rabbit feed. The machine comes in different sizes depending on the intended feed production capacity it can be as low as 50 kg/hour to above 1 tonne/hour. And, different die diameters allows to make the

If you are planning to start your feed pellet making business, or build a complete poultry feed pellet processing plant with high quality equipment,Lima Machinery can provide you with a turnkey project that can guarantee the quality of poultry feed pellets and the daily work efficiency of the equipment .In addition, you can also enjoy a lower price and purchase a complete set of equipment at a time!

1. Automated Chicken Skinning Machine. Designed specifically to achieve the optimal yield for skinned poultry (chicken), our automatic chicken skinning machine process wet and air chilled chickens. The machines can automatically remove skin from the chicken’s whole breasts, breast caps, split breast bones and whole legs of chickens.

Project Name: Small Poultry Feed Production Line. Production Output: 1 ton per hour. Plant Location: Thailand. Application: This feed production line is designed for manufacturing fodder pellets for various poultry animals (Phasianidae and Anatidae) including chicken, turkey, duck, goose, quail, pigeon, etc. Full View of the Poultry Feed Line.

ABC machinery is specialize in designing broiler chicken feed manufacturing process, installation, commissioning and maintaining complete poultry feed mill plant. We also provide customized solutions on feed processing for chicken, cattle, fish, and other livestock animals. We have a vast market for our feed processing machines which includes

Jan 14, 2022 · The client is a project investor who purchased our fully automatic feed mill plant 5 years ago and installed it in Gansu Province, China. The 20TPH poultry feed processing plant adopts a double-line design and has a larger output. It uses two crushing lines, one ingredient mixing line, two pelletizing lines and two packaging lines.

Jun 23, 2022 · From a processing plant in Pennsylvania, Do Good Foods gathers waste grocery food from a 250-mile radius and processes it into chicken feed. “The goal is to eventually be nationwide to fight food waste and fight climate change,” she said. The company plans additional plants in Indiana and North Carolina.

Sammy McKenzie Chicken Processing Company is a world-class and licensed chicken processing company that will be based in the outskirt of Santa Fe, New Mexico – United States. We have done our detailed market research and feasibility studies and we were able to secure a hundred hectares of land to start our chicken processing plant.

These plants operate under the requirements as set by the Federal Meat Inspection Act or the Poultry Products Inspection Act. Currently licensed, permitted E2 plants are listed at Minnesota State "Equal To" Plants. (For a listing of USDA inspected plants, contact the Des Moines District office at 1-800-990-9834 or visit the USDA Meat, Poultry

Step 2: Stunning. Once birds arrive at the processing plant, workers trained in humane handling carefully suspend them by their feet on a moving line. In a matter of seconds, the chickens become calm due to “rub bars,” which provide a comforting sensation on the chicken’s chest. This, combined with low lighting, is used to keep birds calm.