Oct 11, 2018 · For efficiency, you can make a “premix” of the finer, more powdery ingredients, measuring it out in amounts sufficient for 25-lb. batches and storing it until use. When ready to make feed, you grind (coarsely) the corn and peas, dump in the premix, and add the small grains whole. You can mix thoroughly by hand, then feed immediately or

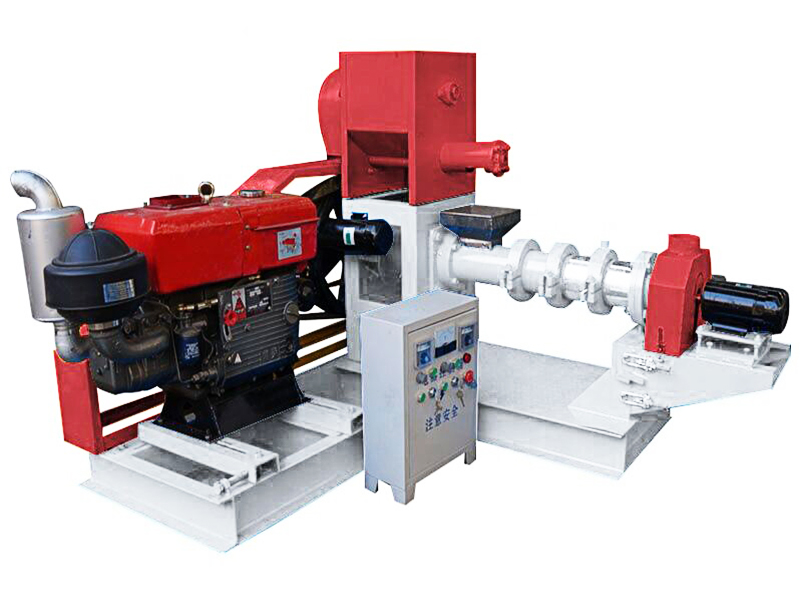

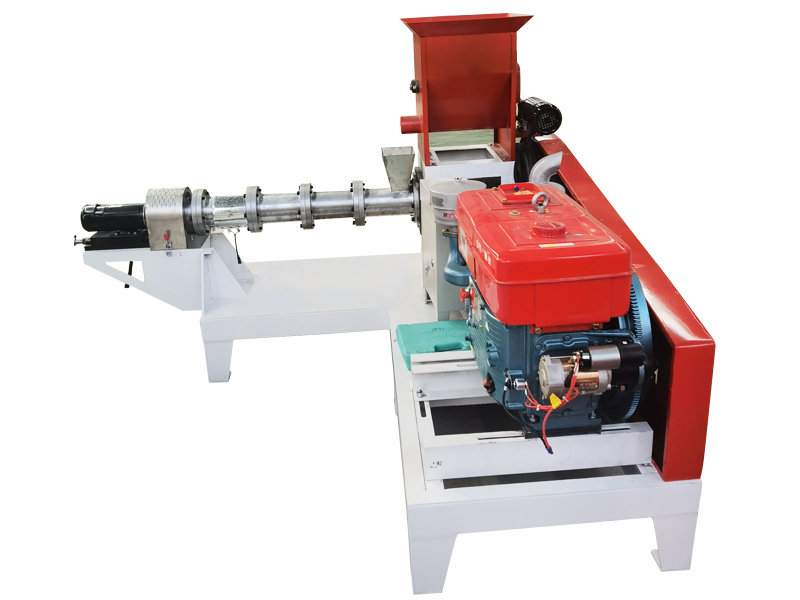

Types: 1) Crusher—-To crush the raw material into powder. 2) Mixer ——-To make all kinds of powder mixed evenly. 3) Extruder—-To make many kinds of feed pellet. Such as fish feed, pet feed. 4) Dryer——–To remove the extra moisture of the pellet. 5) Cooler—— To reduce the temperature of the pellet after dring. 6) Packaging

Dec 01, 2012 · Grinding up the feed so the chickens (especially the smaller chicks) can more easily ingest and digest it. There are plenty of grinders out there, but most of them are this type: the huge PTO-driven mixer-grinders for large-scale operations. At a cost of $3000 on up (not including the tractor to power them) this is not a viable option for our farm.

The chicken feed making machine is an ideal equipment for chicken broiler layer breeding. It is of great significance for feed maturation, increase nutrition, improve absorption, convenient storage and transportation, adapt to the chewing function of animals, and high-yield and high-efficiency livestock breeding.

The chicken feed pellet mill machine has good raw material versatility and can be used for the granulation of various raw materials such as corn, sorghum, wheat, beans, and oilseed meal. At the same time, the chicken feed production plant has the characteristics of low energy consumption, high production efficiency, and large profits.

1. Feed grinder There are two feeding methods for poultry feed mill machine: self-priming and forced feeding. When the material is sucked or sent into the crushing chamber, the high-speed rotation of the hammer is used to crush the material and use screens to ensure the granularity of crushed feed. 2.

2021/08/03 · Setup a Small Chicken Feed Processing Mill. Making high quality chicken feed from scratch is never an easy task. Though a proper feed is prepared from 85% -90% of cereal grains, it cannot be completely made of grains. The feed must include soybean meal, salt and concentrated vitamins and minerals as well.

It has the unique advantages of simple structure, small footprint, favorable price and low consumption, and the chicken feed making machine is an ideal choice for small scale industrial production,chicken farm and large feed production factory.Raw materials for chicken feed machine are readily available, such as grain like corn,soybean, wheat bran, rice, beans, etc. the chicken feed processing machine is driven by electric motor which is more energy saving and environmental protection.of

1. There are not many poultry raised by individual family farmers. A single-phase small chicken feed pellet machine can be fully satisfied. The equipment can produce 60-100 kg of feed per hour. 2. If the scale of the farm is relatively large, the farmer can choose a ring die pellet machine with a relatively large output. 3.

The process of making chicken pellets for your chicken is simple and it involves: Use a feed hammer mill to grind the ingredients so that they become fine powder ingredients/mashed potatoes. Next, mix all the ingredients in the feed mixer and wait until the mixture is even. The moist viscous mixture shall be the final mixture.

The chicken feed making machine is an ideal equipment for chicken broiler layer breeding. It is of great significance for feed maturation, increase nutrition, improve absorption, convenient storage and transportation, adapt to the chewing function of animals, and high-yield and high-efficiency livestock breeding. Get Price

Step 1: Draft a feed milling business plan. Having a business plan is extremely important before even starting your feed mill business. It is very unlikely that you will have all the information before you start, so you will need to make changes as you go along. So, if you are considering building a feed mill, you need to first draft a business

Bright Prospect of Investing Layer Chicken Feed Making Machine Factory in Bangladesh. Bangladesh is one Muslim country, Islam is the state religion, and the population who believe in Islam accounts for 88.3% of the country’s total population of approximately 140 million the breeding industry is dominated by poultry including layers, broiler chicken etc.(Read more: mobile pellet plant>>)

More and more farmers and investors have begun to purchase poultry feed pellet machines to process and produce feed pellets for setting up a poultry feed mill, poultry feed pellet machines It has become an ideal small-scale feed processing equipment in the minds of farmers and feed manufacturers.

A chicken pellet making machine can be used to make pellets for cattle feed, pig feed, chicken feed, horse feed, duck feed, fish feed and even rabbit feed. The machine comes in different sizes depending on the intended feed production capacity it can be as low as 50 kg/hour to above 1 tonne/hour. And, different die diameters allows to make the