Sep 30, 2021 · Brief Production Process Of Making Chicken Feed Pellets For Layers 1. Crushing: Crushed raw materials by hammer mill type feed crusher to get fine grinded ingredients. 2. Mixing: All of the ingredients are mixed in a feed pellet mixer for a period of time to get a uniform mix. Then a 3. ...

Scratch and Peck Feeds Naturally Free Organic Layer Pellets Chicken Feed with Grub Protein - Non-GMO Project Verified, USDA Organic - 2024 4.4 out of 5 stars 126 $45.99 $ 45 . 99 ($0.11/Ounce)

Mar 01, 2020 · These two types of feed are essentially comprised of the same ingredients and serve the same purpose — keeping those hens healthy and happy. Whether you’re new to owning chickens or simply on the search for a chicken diet mix-up, let’s walk through the distinctions and similarities between these chicken feed types. Buy Chicken Layer

A complete feed for laying hens from 3 weeks prior to point of lay. 17% Protein level, ideal to help hens lay eggs regularly. Source of calcium. Contains essential oils and fats. Composition: Wheat, Wheatfeed, Hipro Soya Bean Extract (GM#2), Calcium Carbonate, Barley, Sunflower Extract, Grass Meal, Vegetable Oil, Dicalcium Phosphate, Sodium

16% Layer Feed - 20+ Weeks. Best Results: Taste the difference with deeper, golden yolks, stronger shells & consistent egg production. Quality Feed: Organic & Non-GMO, corn & soy free, sourced locally, milled fresh. Healthier Chickens: Shinier plumage, brighter colored combs, stronger & more confident chickens with higher activity levels.

Dec 12, 2020 · Layer feed is a mixture that helps chickens grow strong and healthy. It offers them a balanced mix of nutrients, vitamins, and minerals. It’s feed specifically for laying hens, and has healthy amounts of protein and calcium. Your hens need a lot of both to lay healthy eggs! Example of layer feed ingredients.

The nutrient composition of this feed is low compared to the starter diet. The grower feed for chickens contains 16 percent crude protein for pullets and 20 percent crude protein for broilers and high energy, the protein content has been reduced to the level required by the birds. The energy content is much because the birds are now grown and

Brief production process of making chicken feed pellets for layers. 1. Crushing: crush raw materials by hammer mill type feed crusher to get fine grinded ingredients. 2. Mixing:all of the ingredients are mixed in a feed pellet blender for a period of time to get a uniform mix. Then a moist, cohesive mash was obtained at end of the final

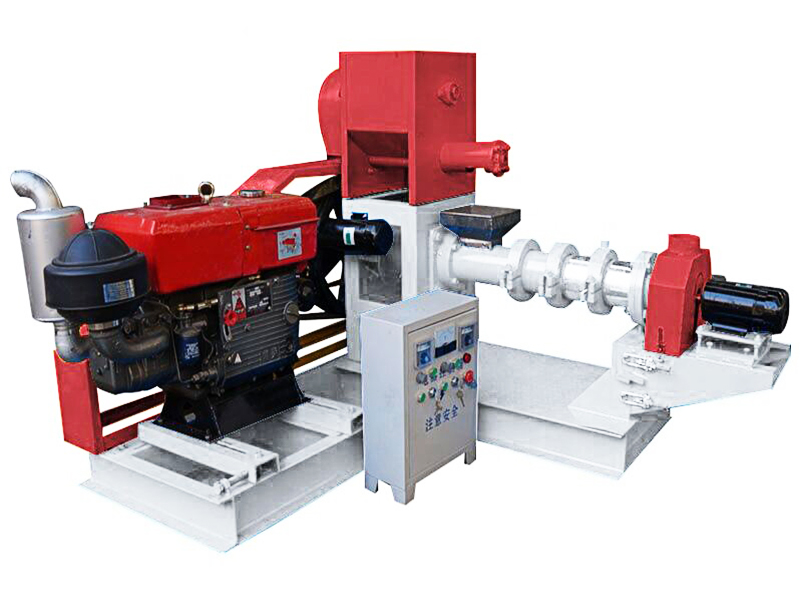

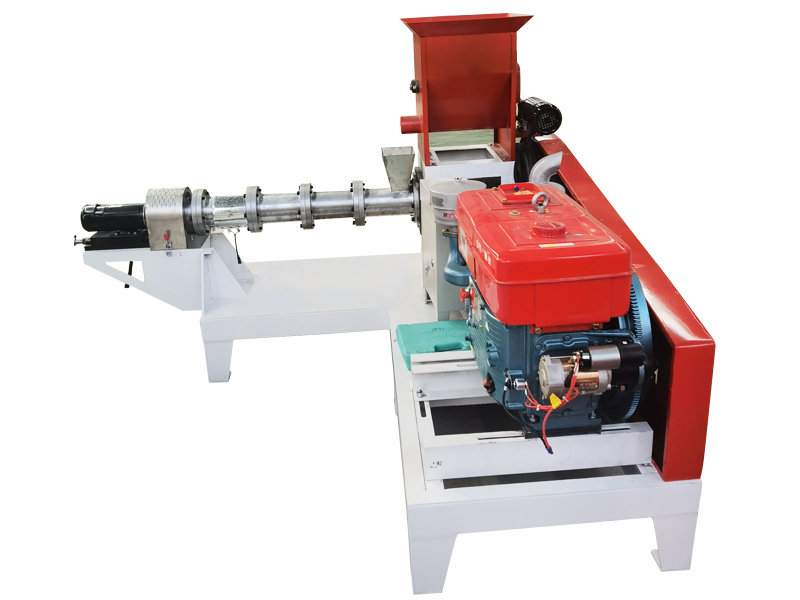

Flat die poultry pellet mill production machine mainly suitable for medium-and small-scale farming professional households and other processing of various livestock and poultry and aquatic pellet feed can reduce the cost of aquaculture.Feed machine can be used for raising rabbits, chickens, ducks, geese, fish, pigs, cattle, sheep, aquatic products and so on.

Buy a 2000 lbs. pallet of organic chicken feed. Save 75%+ buying bulk! Choose layer, grower, starter & pellet, mash, whole grain. Organic, Non-GMO, corn-free & soy-free. FREE shipping. 100% sourced from local, US family farms. 100% Satisfaction Guarantee. Larger & Tastier Eggs, Happier & Healthier Chickens.

Directions For Use: Feed Manna Pro Non-GMO Layer Mini-Pellets to laying hens beginning about 16 weeks of age (prior to the onset of laying), through the laying period. Give laying hens free access to feed, allowing them to consume all they want. This product is also suitable for laying ducks and geese (see chart below).

Mar 30, 2019 · Layer poultry farming means raising egg laying poultry birds for the purpose of commercial egg production. Layer chickens are such a special species of hens, which need to be raised from when they are one day old. They start laying eggs commercially from 18-19 weeks of age. They remain laying eggs continuously till their 72-78 weeks of age.

Chicken Feed Pellet Making Process Step 1: Make a Premix The premix is later on added to the whole grains. The premix can be made beforehand and stored then used when you is making the feed. The premix is made by mixing the powdery ingredients; cultured yeast, fish meal, kelp, flax seed, crab meal, salt and aragonite.

Feed Mill Parameters. Type: ZLSP 150B. Driven by: Electric Motor. Power: Three phase 4. Output: 90-120 kg/h. Weight: 95/110 kg. Package Size: 800x450x700. Application: Widely used for making chicken, duck, fish, cattle, pig and other kinds of poultry & livestock animal feed pellets.Lima Machinery is an experienced manufacturer of feed mill

Feed Pellets for Chicken in Different Stages. The nutritional requirements of chickens differ somewhat at different stages of growth. For the chicks, starter feed is needed, containing 20% protein, the highest percentage of protein a layer will ever consume, which makes the chicks grow rapidly in the first few months of life.