MZLH520 Chicken Manure Pellet Making Machine. The MZLH520 series rice chicken manure pellet making machine has a larger ring die and pelletizing chamber to ensure high-efficiency chicken manure pellet production. In order to adapt to lighter raw materials, we have added a forced feeder. Power: 160KW. Capacity: 3-4T/H.

For a small chicken feed pellet machine, the average cost can be as low as $300-$400. But such a feed mill would obviously be small with a low output. Therefore, standard pellet machines for chicken feed production are more expensive. You can prepare a budget of $2000 – $7000.

contact info. Address: #4 building One Belt One Road Industry, Jinshui District, Zhengzhou, China Phone: +86-371-55680556

Working Principle of Flat die chicken feed pellet making machine The first design of feed pellet machine to be used was the flat die pellet pellet machine for animal feed machine, developed at the start of the 20th century to process animal feeds pellet. This design of feed pellet machine was based on a vertical design, where material fell onto a roller section sat on the surface of a horizontally mounted die.

With pellets you can add the necessary vitamins and minerals in exact amounts and you can be confident that the chickens have consumed them. And you can also store much more feed in a smaller storage space. In terms of making your own chicken feed pellets, you can start with a feed pellet machine.

Chicken manure pellet machine is an important equipment to produce commercial chicken manure fertilizer pellets. In view of its nutrient elements, chicken manure is a kind of good fertilizer. After composting, you can make granular chicken manure fertilizer for commercial purpose. In addition, organic chicken fertilizer pellets are more convenient for transportation, application and storage.

2 Shunxin chicken litter pellets processing machine for sale. 2.1 Small scale chicken litter pellets making machine for sale; 2.2 Small scale chicken manure pellet machine for sale; 2.3 Drum pelletizer for large output chicken poo fertilizer pellets manufacturing; 2.4 30T chicken poo drum pelletizer for sale

The chicken manure dryer is used for drying raw materials with excessive moisture, and drying the raw materials with about 20% moisture. The granulating molding of the following sections is done once. Main Equipments: Chicken manure dying machine: LYHG2.0*20, roller diameter 2m, length 20m, power 22kw.

Feed Pellets for Chicken in Different Stages. The nutritional requirements of chickens differ somewhat at different stages of growth. For the chicks, starter feed is needed, containing 20% protein, the highest percentage of protein a layer will ever consume, which makes the chicks grow rapidly in the first few months of life.

1. There are not many poultry raised by individual family farmers. A single-phase small chicken feed pellet machine can be fully satisfied. The equipment can produce 60-100 kg of feed per hour. 2. If the scale of the farm is relatively large, the farmer can choose a ring die pellet machine with a relatively large output. 3.

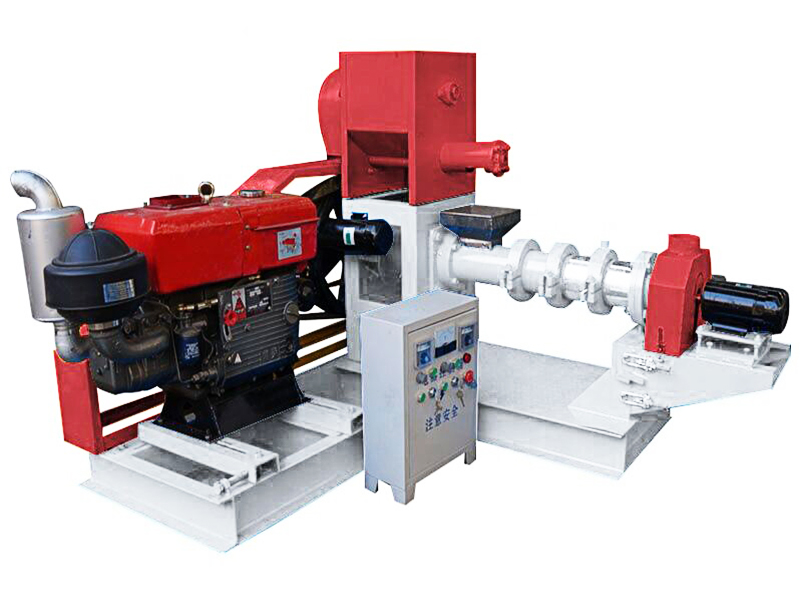

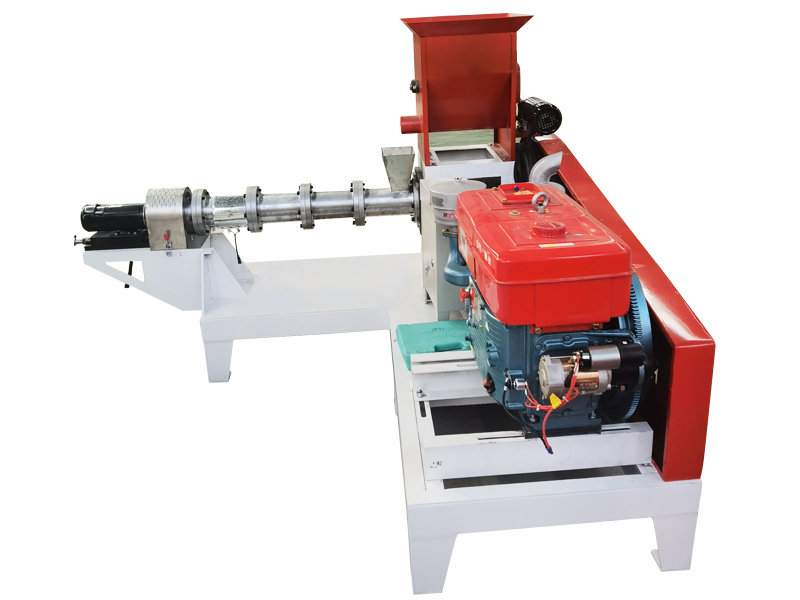

Oct 11, 2018 · For chicken feed pellet mill with flat die design, we have two kinds of driven engine, one is electric motor, the other is diesel engine. Which engine to choose, just depend on you local condition. Among all these flat die feed pellet mill, AZSPLM-260B feed pellet mill is our hotsale one, as it has medium capacity 400-600kg/h.

The pan type chicken manure granulation equipment mainly pelletizes by the disc pan. There is a plate on the granulator. When it begins, the pan will rotates. And then the powdery chicken manure will rotates with the pan. The chicken manure material will not be out until it becomes granular fertilizers.

Both chicken manure and cattle manure is suitbale for making fertilizer pellets. According to the test, the organic matter content of chicken manure is 25.5%, the nitrogen is 1.63%, the phosphorus is 1.54%, the potassium is 0.85%, and the content of three elements in chicken manure is equivalent to 4.5-7.7 times of that in cow dung!

Adopt screw center pressure regulating structure, mold clearance can be large or small. The die plate is available on both sides, and it can provide 2.5-10mm aperture of various die plates, which is suitable for different materials to produce high quality feed pellets. The pellet density by our chicken feed pellet machine can reach 1.1*103kg/m3.

Aug 09, 2020 · Phase 1: First screening. Phase 2: Composting. Phase 3: Clump selecting. Phase 4: Refining. Phase 5: Pelleting. Phase 6: Cooling. Phase 7: Sieving. Phase 8: Packaging. About more information about easy use chicken manure organic fertilizer pellet machine price,making chicken manure pellets, please feel free to contact Richi Machinery.