Location counts a lot when starting a livestock feed mill business. In selecting the right location for your feed milling plant, you’ll need to consider areas with significant agrarian activity. In other words, part of the criteria should include areas with a significant level of agricultural activity.

Feed Mill. You are here: Main; Ranch; Feed Mill < All Topics. Build Cost: $5,000 Needs a rancher or an ATV that fetches Wheat and Water for the mill. Previous ...

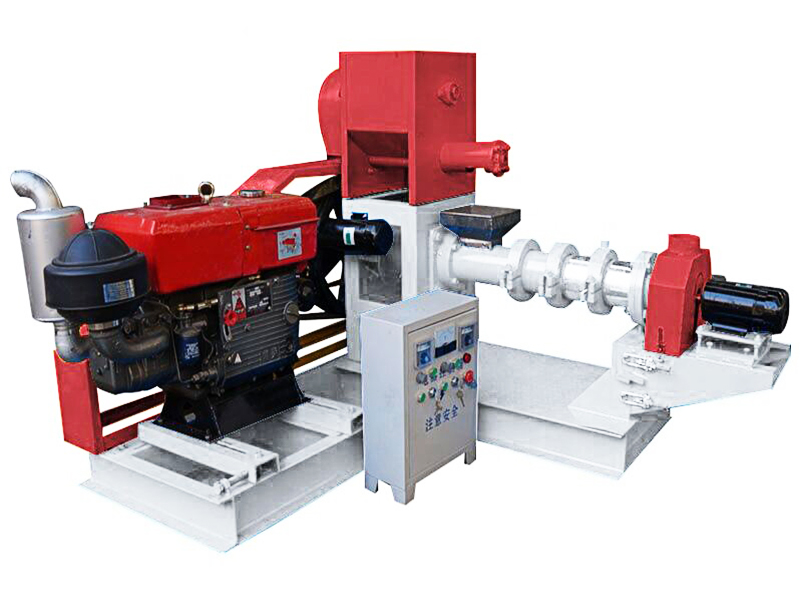

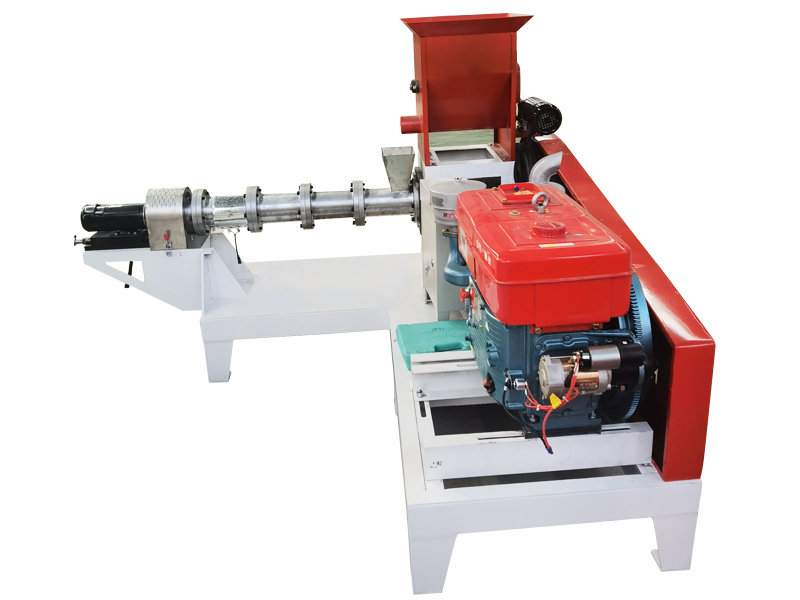

The animal feed mill we provide covers all types of animal feed, and can produce various pellet feeds, powder feeds, premixes, concentrated feeds, etc. At present, we have established hundreds of complete feed mills in more than 100 countries around the world, with a minimum output of 1 ton/h and a maximum output of 100t/h. Get Price & Support.

It is the first step to establish a cattle feed manufacturing plant for the ones who are planning to start their own business of beef cattle feed production. If you are planning to establish a cattle feed production plant and start your feed processing business , you have to know about the local feed market and also have a clear understanding of how to develop a customized business plan for your feed factory, so that to make the BEST project plan with low investment and low production cost.

Mar 07, 2019 · Brief production process of dairy cow feed pellets. 1. Crushing: crush raw materials by feed hammer mill to get fine grinded ingredients. 2. Mixing:all of the ingredients are mixed in a feed pellet blender for a period of time to get a uniform mix. Then a moist, cohesive mash was obtained at end of the final mixing. 3.

Nov 13, 2020 · For example, you might start cows on oats because oats are easy to digest. However, oats contain fewer calories and less protein than other grains. As your cows get closer to processing, you want to shift their diet away from oats to a high-calorie grain to ensure they make weight.

How to Make Pig Feed Pellets. Pig feed pellets is processed under the action of 100 ~ 120℃ hot steam. It is easier for pigs to digestion and absorption. Pig feed pellets making process including raw materials crushing and mixing, conditioning and pelletizing, cooling and packing.

Dear sir, I want to start a manufacturing unit of cattle feed. I want to know in detail about cattle feed production line, machines, plant cost and the area required and the licensing authorities. please send details for formulation, ingredients, machine supplies etc. My location is - M.I.G. B / 9, Gujaini, Kanpur - 208022. (U.P.)

cow eating farm feed grinder low cost philippines Treating ForagesProcessing hay for beef cows, especially if it is low quality, high in stems or stalks, or badly weathered, can result in feed savings as high as 10-15%.

Frank moved to Nacogdoches in 1982 and worked his way through college in the Pet Food plant. After graduation, he managed production shifts in the feed mill and the pet food plant. In 1992, Frank became the General Manager of Lone Star’s Keatchie, Louisiana plant. Since 1996, he has been a District Sales Manager in the Feed Division.

Ordinarily, sole proprietorship should have been the ideal business structure for a small – scale poultry feed mill especially if you are just starting out with a moderate startup capital in a small neighborhood. But people prefer limited liability Company for obvious reasons. 8. Choose a Catchy Business Name.

Grinding feed with a New Holland 352 Grinder/Mixer

Set up Small Cattle Feed Pellet Plant to Obtains Big Benefits. Small cattle feed pellet machine can also be used to set up small feed processing plant. The cattle feed pellet plant is appropriate for both medium and small scale farmers mainly made of simple structure with small foot print and it has a low noise.

5 Steps to Starting a Livestock Feed Production Business from Home. 1. Feed Formulation. First, you have to come up with a formula. This would depend on the livestock category you want to produce for. Of course, the formula for chicken feed would be different from fish feed. To come up with a good formula, you should learn about the nutritional

Purina® Plus is one of the first national value-added program to combine a complete nutritional foundation, proven health protocols and progressive management to distinguish high-value calves in the market. Developed in collaboration with leading animal health brands, this innovative program offers cow/calf producers the flexibility to choose