Apr 01, 2013 · Biblis plant, Herzogenbuchsee. The Biblis plant was constructed in 2001-02 and was energy-efficient from the start. A multi-stage grinding system using two-pass crushing mills and vertical-rotor hammer mills reduced the energy requirement by about 30 percent in comparison to a direct grinding system.

Jan 29, 2014 · Traditional cattle-feeding enterprises grow weaned calves (450 to 600 pounds) and yearling steers or heifers (550 to 800 pounds) to slaughter weights of 1,100 to 1,400 pounds. Cattle-feeding operations exist in all regions of the United States, but most large operations are in the Great Plains from Colorado and Nebraska to Texas.

Cattle Feed Plants are used to prepare Feed for Cattle, Buffaloes, Cows, Horses etc. ‘GNE’ manufacture superior quality cattle feed plants. Our production ranges from 1 ton to 30 ton per hour. We manufacture manual, Automatic, Fully Automatic CNC Cattle Feed Plants.

Grinding feed with a New Holland 352 Grinder/Mixer

May 07, 2018 · Assume that initially the mill wants to produce 2,000 tons per week operating 40 hours per week. Two years later, the projected mill capacity will need to be 3,000 tons per week. And production will operate 50 hours per week. In five years the projected capacity needs to be 5,500 bushels per week and production will operate 96 hours per week.

Indians. The Indian animal feed industry is broadly categorized into Poultry, Cattle and Aqua feed (majorly Fish). Though the organized sector is quite old, it is still in a nascent stage, supplying only 10 per cent of cattle and aqua feed and 50 per cent of poultry feed in India, says a Rabobank report. The bulk of

Home sh.shuanghe@gmail.com 2021-10-12T02:04:26+00:00. Double Crane Machinery is a leading manufacturer & supplier of turnkey project solutions for poultry feed mill plant, animal feed processing plant, aqua feed plant, cat litter production line etc. As a professional feed mill plant manufacturer, supplier and exporter.

mill operator in the way of knowledge and ability. The skill of the pellet mill operator, through his ability or mistakes, influences plant profitability. Pellet mill operators have a vitally important role in the manufacture of animal feed. They should recognize this responsibility and the great contribution they make to an efficient feed plant.

How to start a cattle feed processing plant can be divided into the following six steps: 1. Cattle feed formula and processing technology selection 2. Selection of cattle feed processing equipment 3. Layout and construction of cattle feed processing plant 4. Purchase and install cattle feed processing equipment 5.

Apart from locally available feed resources, compounded cattle feeds and strategic feed supplements are important source of nutrients for growing and lactating animals. To ensure that these feeds and feed supplements are manufactured in a cost effective manner and in

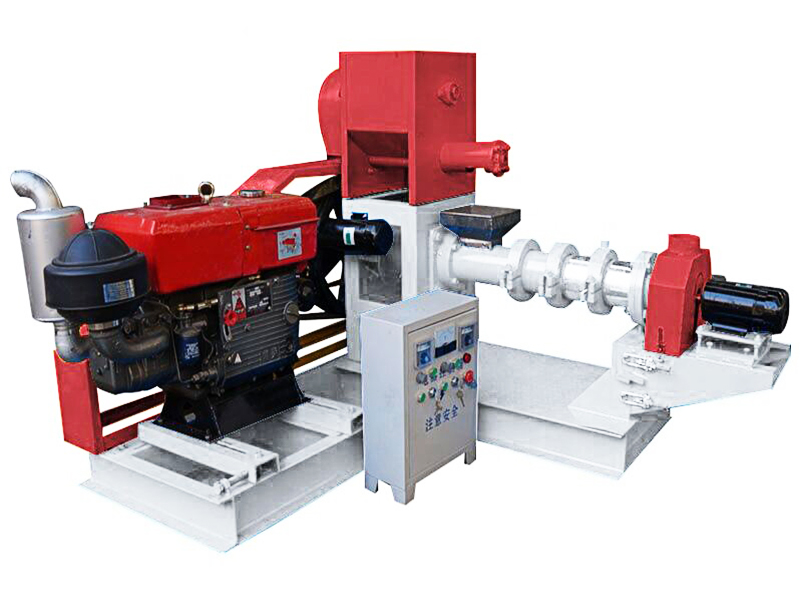

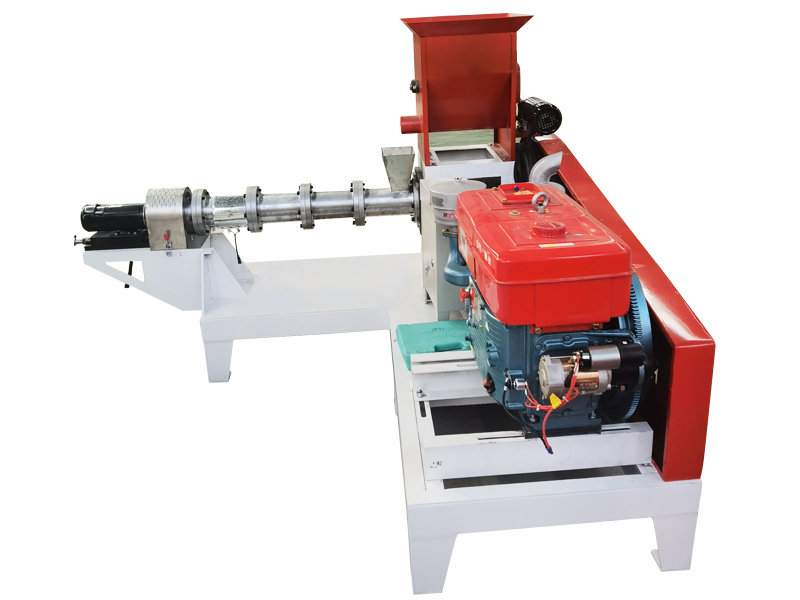

The feed mill plant unit includes equipment of grinding, mixing, pelletizing and cooling. The bagging machine is also available to be included if you need. It is suitable for small and medium sized farms and feed mills to use. If you are planning to start mini or small scale feed mill plant for herbivore and ruminate animals, you can take this feed milling project for reference.

Equipment to Start Cattle Feed Production. A hammer mill is to crush the raw materials into small sizes to meet the requirement of a cattle feed making machine. Dryer machine is to dry the raw materials. Mixer is to mix multiple raw materials evenly. Animal feed pellet machine is to pelletizing the loose raw materials into high density cattle

May 25, 2021 · Feed Mill Project Report – Profit in Feed Mill Business in India Profitability = Sales – Cost of Production = Rs. 14,00,000 – Rs. 11,72,000 = 2,28,000. Profit Margin in Electronic Shop in India: Investment, License, Project Report, and Business Plan

Additive feed : Amino acid, vitamin, antibiotic, antioxidant, etc. The small cattle feed plant cost is closely related to the production output, process design and equipments included in the plant. The equipment cost is about 10,000 ~ 17,000 USD. Jsut feel free to get in touch with us for FREE Quotation List, and get other details of our cattle

The height of the equipment is about 5 meters. Mini Feed Pellet Mill Application. It is suitable for farms of cattle, sheep, pig, poultry and other animals and small and medium-size feed pellet mill factory and so on. Min Feed Pellet Mill Use Requirements. The compound feed should be made according to the scientific formula of a variety of