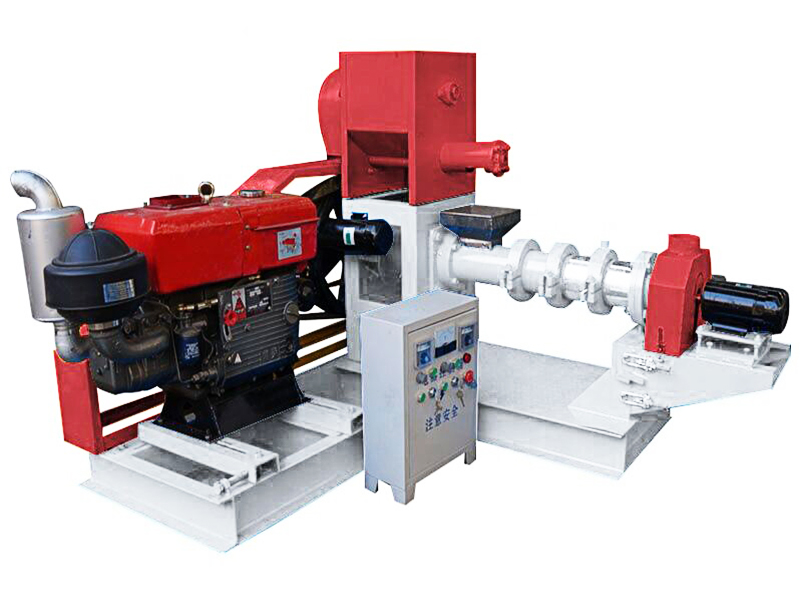

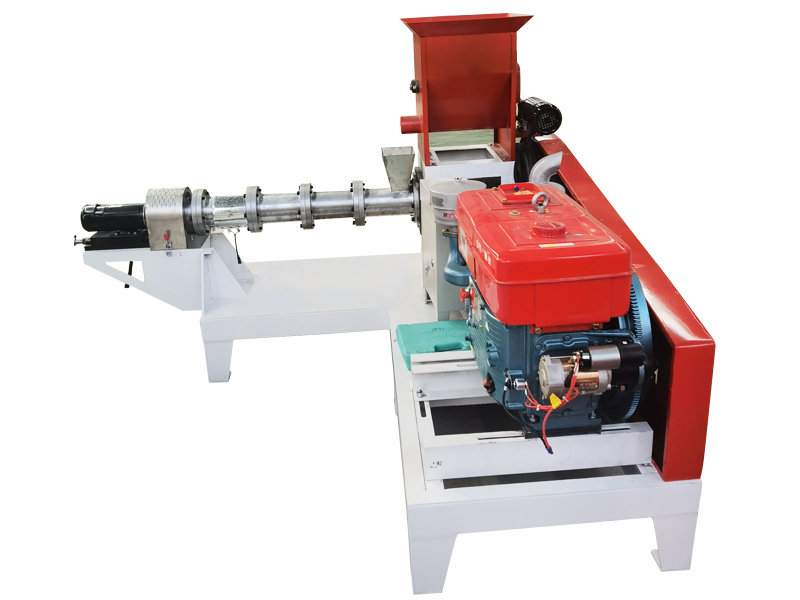

This Poultry Feed Making Machine can be used to make feed pellets for all ages chicken. Customer Visit Packing & Delivery Popular Design For Cape Verde Dimension 13(L)*3(W)*8(H)m Capacity 1-2 t/h Final Pellet Size 1.5mm to 6mm Information This small poultry feed production line can make poultry feeds and livestock feeds, also can make powder feeds and pellet fees.

Make chicken manure or cow dung into fuel pellets/briquettes – buy high quality manure pellet/briquettes machine for biofuel making business: HOT Sale chicken manure cow dung pellet and briquette machines offered by pellet and briquette machines manufacturer or supplier - guide on process of make chicken manure cow dung into fuel pellets briquettes production and how to start chicken manure

Small Animal Feed Pellet Production Line Startup Cost. More and more farmers tend to make feed pellets for their own chicken, goose, cows, goats, and more to reduce the feeding cost, which is definitely a great idea. In order to meet more customer’s demands,Lima Machinery not only offer large scale feed pellet plant, but also provides the small scale animal feed production line that is in compact size and is very much suitable for home use or farm use.

1. Cow dung drying: different from making other biomass fuel pellets, the first step for making cow manure fuel pellets would be drying. Because there is too much water contained in the cow manure. If crush the cow manure first, the too wet manure may probably block the crushing machine. After drying, the moisture of mature is decreased to

5 Working Steps offish Pellet Machine For Sale. Working Process of Making Pellets. Shred to the required size: use the crusher to make raw material: 2-5mm in diameter. If your raw material is 1-2cm that can be pelleted directly without a crusher. Crusher is equipped for large diameter raw materials.

Cow dung fuel pellets can replace coal to be used to supply heat or as fuel. It is especially suitables for densely inhabited district. 2.It has no season limitation and can be used all the year round. 3.Making cow dung fuel pellets can reach conversion and appreciation of waste material. 4.Environmental friendly.

Apr 15, 2016 · It is fed into the feed pellet machine and then to the roller and die extruder. (Note: feed pellet better for home use) When the mash is compacted through the die, soft, moist pellets were formed. The extruded pellets have a moisture content of 16-17%. 4. Drying: the wet pellets are dried to obtain moisture content below 12%.

So drying machine is important in pellet line. After drying, the moisture content of cow dung goes down to 8-15%, which we can prepare for the next step. 2. Grinding: If the size of cow dung is big, the hammer mill is necessary, which can make cow dung into fine power. 3.Pelleting: After grinding, you should put the cow dung fine power into the

This Poultry Feed Making Machine can be used to make feed pellets for all ages chicken. Customer Visit Packing & Delivery Popular Design For Cape Verde Dimension 13(L)*3(W)*8(H)m Capacity 1-2 t/h Final Pellet Size 1.5mm to 6mm Information This small poultry feed production line can make poultry feeds and livestock feeds, also can make powder feeds and pellet fees.

SKJ3-550 Cow Dung Fertilizer Pellet Machine 2000kg/H Organic Pellet Press Machine Get Best Price Farm Using Flat Die Type 45KW Fertilizer Making Machine CE Approved

Process Flow of Organic Fertilizer Pellet Factory. To prevent deterioration of your pellet fertilizer during storage, reduce their moisture content to around 20% or less. This will ensure your pellets do not become moldy. Making cow dung into pellets for fertilizer is an easy, affordable way of maximizing the use of the biomass from your cows.

This kind of cow manure fertilizer pellet machine also called stirring teeth granulator. When granulating, cow waste rotating with the stirring teeth and rolling to balls. You can predetermine the pellet size by adjusting the speed of rotor. To meet your different requirements of capacity, we designed 5 models of this granulator.

Here we will introduce the steps of managing cow manure as the followings. Ferment the cow droppings properly. You can use Shunxin compost making machine and organic fermentation pot to process the fresh cow litters, make them safe. Use Shunxin fertilizer crusher to shred the cow feces bulks to pieces.

Crushing: In order to prevent cow dung from caking, a cow dung crushing machine is indispensable on your commercial cow dung fertilizer production line. It can evenly crush your materials into powder, facilitating you to make them into better fertilizer. Moreover, substandard fertilizer pellets require the process of crushing.

Runbo animal feed pellet making machineWebsite:https://www.runbomachinery.com/animalfeedmachineEmail: info@runboworld.com Whatsapp: +86 19948016426