.jpg)

Dog Chewing Snack Machine can make dog chewing food is made of many kinds of different materials with scientific configuration and extrusion in the extruder.this kind of product can be made into a variety shapes such as stick, bone, etc. Advantages: 1.different combination screws can produce different products. 2.easy to operate.

.jpg)

Apr 20, 2024 · Dog food extruders are vital pieces of equipment in the pet food manufacturing industry. These machines are specifically designed to produce various types of dog food products efficiently and consistently. Utilizing advanced technology and engineering, dog food extruders ensure that the nutritional requirements of dogs are met while also

.jpg)

High quality SLG70 Pet Dog Chewing Food Extruding Machines Dog Feed Chew Stick Processing Line Making Machine from China, China's leading Pet food machine product market, With strict quality control Pet food machine factories, Producing high quality SLG70 Pet Dog Chewing Food Extruding Machines Dog Feed Chew Stick Processing Line Making Machine products.

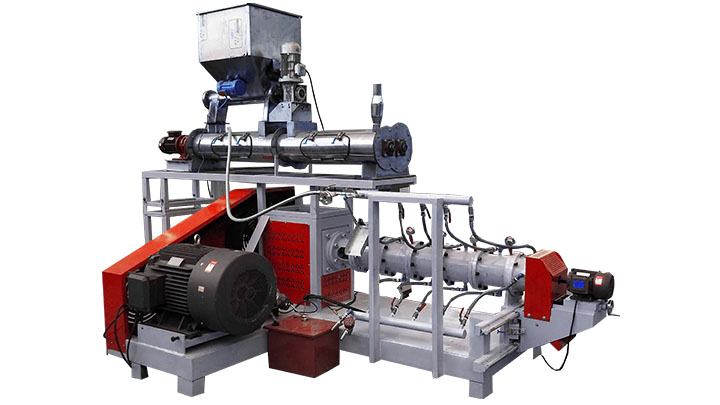

Dog chew food making machines mainly include mixing machines, screw conveyors, single screw extruders, cooling machines, cutting machines, elevators, and ovens. All these devices work together to ensure a smooth and efficient production process.

Rawhide Dog Snacks manufacturing Machine , dog food maker machine. Customized Native color Pressed Rawhide Bones dog chews Machine. Flour Column and Three Board Rawhide Pet Bone dog food machinery with ISO9001. Low consumption Snacks Food Puff Extruder Machine / puff maker machine. Twin Screw Wheat Flour Corn Puff Food Snack Extruder Machine.

.jpg)

This pet food production line has high stability and automation performance, and can control the expansion of the extrudate in a variety of ways. Refers to controlling the texture of the final product. The machines are all made of stainless steel. The dog food production line has a reasonable design and a high degree of automation.

Nov 22, 2020 · Extruded pet food ingredients for small companies. At a typical scale, pet food extruders produce 10 to 12 tons an hour, Henry said. “The process of extrusion is really an extraordinarily high throughput starch cooking machine,” moderator Greg Aldrich, associate professor and pet food program coordinator at Kansas State University, said

.jpg)

The dog treat production line adopts single screw extrusion technology, which is an innovative product of the manufacturer's engineers. The pet treat production line uses starch, flour, animal skins and other food additives as raw materials, and uses unique extrusion methods and molds to produce various dog chew snacks in strip, rod, twist, two-color or multi-color shapes.

.jpg)

High quality Stainless Steel Dog Food/ Chew Snacks Making Machine Extruder from China, China's leading pet extruder machine product, with strict quality control dog food making machine factories, producing high quality dog food making machine products.

PRODUCT CATEGORY. Food Extruder. Pet Food Machine. Cereal Bar Machine. Find excellent quality food extruder machine, pet food processing line, puff snacks extruder from China Dragons Machine. We have a whole set of quality management system to guarantee the quality and service of our products pet treats equipment, cereal bar machine, etc.

Dog chew making machine dog chewing extruder machine Dog chew making machine dog chewing extruder machine was extruded from co-extruder, it can be made into many kind of shapes such as stick, bone, bi-color, bi-flavor, etc. This kind of food not

.jpg)

Soft Chewing Dog Snacks Cold Extruder Machine: Capacity: 200-300kg/hr: Air Source: 0.5-0.8Mpa: Air Comsumption: 90L/min: Quantity Of Placing Tray One Time: Customized: Motor: Siemens/Leadgo: Plc: Siemens: Use: Make Meat Strips: High Light: Soft Chewing Pet Treat Machine, Soft Chewing Dog Food Extruder Machine, Soft Chewing Dog Food Extrusion

Oct 21, 2021 · In a previous study, we explored the effects of changing processing parameters to create a surface response model to predict RS content in a dog food using a small-scale twin-screw extruder . The treatment with the lowest extruder shaft speed (SS), highest in-barrel moisture (IBM), and greatest particle size yielded the greater RS.

QL-120S. 300-400kg/hr. 150kw. 30 x 5 x 3m. System Advantage: Main Equipment List. I. Flour Mixer or Double Shaft Mixer. The mixer is the first step in the extrusion line, where the raw materials are combined according to the formulation of the pet treats. Ingredients such as protein sources (meat, fish, or vegetable), grains, vitamins, minerals

.jpg)

Dog chew making machine dog chewing extruder machine Dog chew making machine dog chewing extruder machine was extruded from co-extruder, it can be made into many kind of shapes such as stick, bone, bi-color, bi-flavor, etc. This kind of food not only provide protein, fat, vitamin, nutrition for dogs, but also satisfy