6.Extruded fish feed can be made in different forms, such as floating feed, sinking feed, and slow-sinking feed, etc. to meet different fish farming methods, reduce feed waste and water pollution. 7.The extruded feed can be sensed as attractant by fishes via varying its shape based on fishes’ preference.

.jpg)

The formulation of sinking fish feed plays a vital role in the health and growth of the fish. Organic ingredients and the right Fish Feed Pellet Size contribute to the feed’s efficiency.The process of sinking fish feed formulation is a sophisticated and critical phase that ensures the nutritional needs of different fish species are met.

.jpg)

Reducing feed waste: Floating fish feed has good water stability, floating in water long for several hours, hence avoiding the dissolution of nutrients in the feed and the sinking of feed into the mud, reducing feed waste to a large extent. According to tests, using floating fish feed can save about 10% of feed than using powered or hard pellet

The wet-type fish feed extruder machine is widely used in making both floating fish feed and sinking feed pellets for aquaculture farms, feed mills, livestock farms, and poultry farms. Different from the dry type floating fish feed pellet mill , the wet type is equipped with a boiler that can continuously steam the materials to make pellets.

.jpg)

Dec 1, 2020 · The test method of sinking rate is to choose one hundred of dried extruded fish feed pellets randomly and then put them in to 3.5% salt water with temperature of 20 ℃ and record the number of

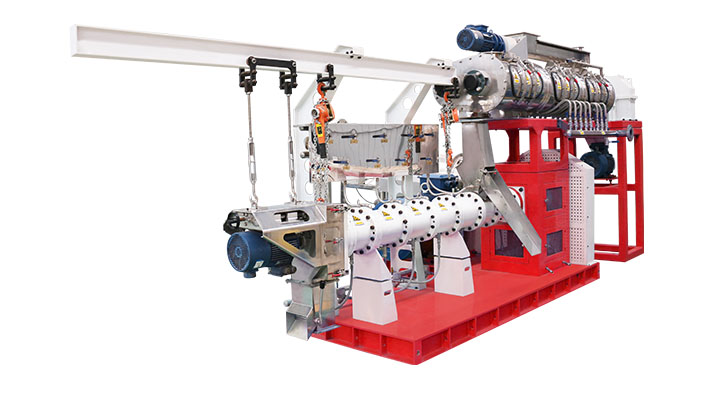

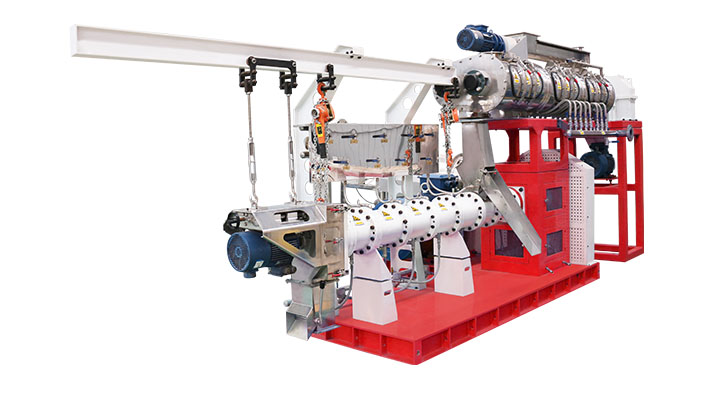

The RCPH120*2 extruder machine for fish feed is mainly used for the 1.5-2t/h production and processing of various floating aquatic feeds. The new type conditioner can soften material fibers, improve gelatinization degree, reduce power consumption and increase production capacity. Main power: 75kw.

.jpg)

Small Pet Food & Aquatic Feed Pellet Plant ( 100~150kg/h) 1. Crushing Machine 2. baghouse system 3. Mixing Machine 4. Feed Extruder 5. Air Conveyor 6. Belt Dryer 7. Coating Machine. Medium Scale Pet and Fish Pellet Plant ( 200~300kg/h)

.jpg)

One of the main advantages of pellet feed compared to extrusion technology floating fish feed pellets is the lower manufacturing cost. However, it has many disadvantages. One of the biggest disadvantages of pelleting is the rapid sinking rate (an estimated 10% to 15% of pelleted feed is lost to sinking). This means higher feed costs, lower

.jpg)

25/7/2019 · Making sinking fish feed pellets by fish feed extruder requires that the residence time of raw materials in the extrusion chamber should be short. The residence time for making floating fish feed pellets is 30-35 seconds and for making sinking fish feed pellets is 20-30 seconds when using the same fish

.jpg)

APPLICATION: Aquatic feed, pet feed and pig feed industry, etc. CAPACITY: 0.03-2T/H. MAIN POWER: 3-132KW. MODEL: DGP. WhatsApp: +86 138 3838 9622. Email: enquiry@pellet-richi.com. With the rapid development of intensive aquaculture, the ecological and environmental requirements are getting higher and higher. The aquatic extruded feed processed

Our 0.15-60 t/h floating fish feed mill solutions are complete system for producing floating pellets with moderate protein and fat content for feeding warm-water species such as tilapia, eels and catfish. We can help you choose between a single screw and twin screw extrusion process to meet your demands and optimize floating feed production costs.

Customers can choose molds according to their needs. The fish pellet making machine models are complete from 400KG per hour to 2 tons per hour, we have different models to meet the needs of customers. The electric heating device is used to improve the expansion rate and floating time of the feed. The Stock Of Fish Feed Pellet Extruder.

Our ring die pellet mill with conditioner is also available to make high-quality fish feed pellets. Fish Feed Extruder Features and Advantages 1. Floating, sinking, and slow-sinking aqua feed can be produced by adjusting feed formulation and related parameters of expansion. 2. The finished pellets can keep floating for 3-15 hours without

.jpg)

May 12, 2023 · Floating Fish Feed. Floating fish feed is specially-designed to float on the surface of water, making it easy for fish to access and consume. Typically, this type of feed is made by mixing various ingredients such as fishmeal, soybean meal, wheat flour and cornmeal into pellets of various sizes and shapes before being extruded out and extrusion heated to create floating feed.

The fish feed extruder can produce all kinds of fish feed, like floating fish feed, sinking fish feed, slow sinking fish feed, and also semi-humid fish feed. However, as the feed extruding machine has complex operation, high price, and high production cost compared to common feed pellet mill, it is usually utilized in producing high grade