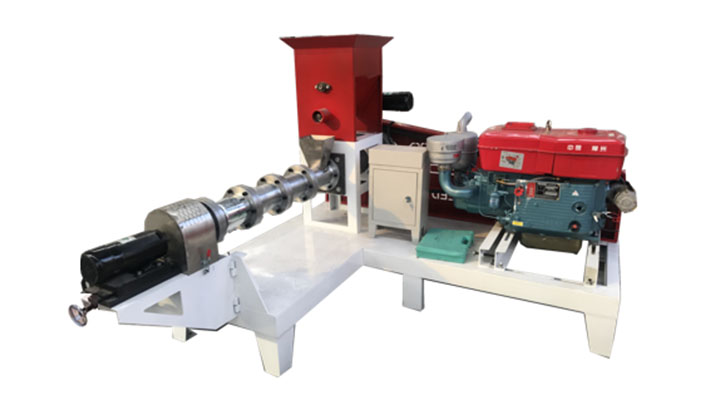

Dec 1, 2021 · Thus, a single screw fish feed extruder was designed and fabricated with locally available and affordable engineering materials. The machine's performance was evaluated with constant

.jpg)

Key Features to Look For. When choosing the right fish feed pellet machine, consider the machine’s efficiency, reliability, and durability. An efficient machine will consume less energy and produce more pellets per hour, which can significantly reduce your costs in the long run. Next, a reliable machine will have fewer breakdowns and require

And increase the extrusion efficiency from 63.25 % to 72 %. Keywords: extrudates, extruder, evaluation, fish feed, floating and performance I. Introduction The extrusion process operates in a dynamic steady equilibrium where input variables are balanced with the output.

.jpg)

This floating fish feed production line adopts fish meal, corn powder and so on as raw materials. This line can be adjusted to produce various shapes of fish feed, shrimp feed and so on. Many production capacities can be chosen according to specific requirements.

The fish feed produced by twin-screw extruder can be easily absorbed by fish and livestock, and can reduce fish disease without polluting the water. Main Components of Twin-Screw Fish Feed Extruder. The main body is made of stainless steel with high safety performance and long service life. The feeding system, driving system and cutting system

.jpg)

The fish feed extrusion process consists of several steps: Ingredient Selection: The first step involves sourcing the best quality raw materials like fishmeal, grains, and oils. Grinding: The ingredients are then finely ground to ensure uniformity. Mixing: Ground ingredients are mixed together in a feed mixer machine.

The floating fish feed extruder allows for precise control over the pellet’s size, shape, density, and nutritional composition, ensuring that the fish receive a balanced and high-quality diet for optimal growth and health. This technology is crucial in the aquaculture industry, where efficiently producing nutritious and cost-effective fish

.jpg)

RICHI fish feed extruder can be used for aquatic feed, shrimp feed, fish feed. Widely used in professional aquaculture plants and large, medium and small aquatic feed processing plants. Mode: DSP. Capacity: 0.1-5 T/H. Main Power: 15-132 KW. According to the characteristics of aquatic feed and many years of experience, we design a fish feed

Aug 15, 2022 · An extruding machine for the production of floating fish feed was designed and fabricated. Performance evaluation of the fabricated floating fish feed extruding machine was done. The

.jpg)

300-500kg/h Floating Fish Feed Extruder Machine – Pet Food May 23, 2017 ... China 500kg/H Chicken/Cattle/Fish Feed Pellet Extruder/Machine Fashionable design top quality animal food pellet machine · Hot Sale...

.jpg)

The aim of this project is to design and fabricate a fish feed extruder with improved qualities and affordable cost using locally sourced materials to aid the production of extruded feeds by local small scale farmers.The design was carried out using engineering principles with due consideration to cost, ease of operation, serviceability

Lima feed machinery offer wet type/dry type fish feed extruder and customized floating fish feed making machine line, Which is suitable for fish, crab,shrimp,cat,dog, pet. Capacity from 30kg/h~5000kg/h

Capacity: 1-10 T/H. Main Power: 15-132 KW. According to the characteristics of aquatic feed and many years of experience, we design a fish feed making machine with double-layer conditioner, which is more suitable for the production of aquatic feed, fish feed and shrimp feed. New multi-channel functional modifier with long retention time.

Learn about the process of making dry fish feed, the characteristics of floating fish feed pellets, and how to choose the right fish feed extruder machine. Expert guidance awaits!

.jpg)

The aim of this project is to design and fabricate a fish feed extruder with improved qualities and affordable cost using locally sourced materials to aid the production of extruded feeds by local small scale farmers.The design was carried out using engineering principles with due consideration to cost, ease of operation, serviceability, durabil