.jpg)

1. Fish feed extruder can produce fish feed in every densities and also produce unlimited types of feed (especially pet foods). 2. Fish feed extruder can process high level moisture mixes and ingredients (until 55%); pellet mill can produce feed pellets with moisture content is about 16-17%. 3.

.jpg)

RICHI sinking fish feed machine is renowned for its robustness and can make high-quality pellets from 0.8 mm to 12mm. We have different sinking fish feed pellet mill and sinking fish feed pellet extruder machine model which is tailor-designed for a diverse aqua feedproduct. Sinking fish feed pellet machines can only make fast sinking feeds.

.jpg)

Key Features to Look For. When choosing the right fish feed pellet machine, consider the machine’s efficiency, reliability, and durability. An efficient machine will consume less energy and produce more pellets per hour, which can significantly reduce your costs in the long run. Next, a reliable machine will have fewer breakdowns and require

.jpg)

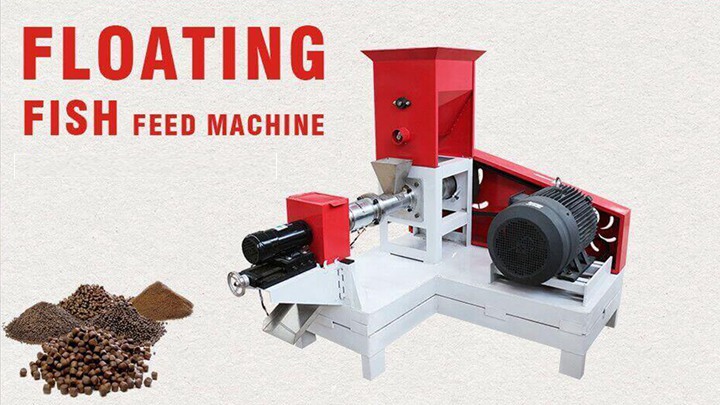

The floating fish feed machine is to convert soybean meal, rice bran, fish meal, bone meal, corn meal, flour, etc. into fish feed pellets with various shapes by heating and extruding. It has a capacity of 40-350kg/h, even bigger. Fish farms or dealers are very willing to invest in this type of fish feed pellet machine.

Extruding fish feed pellet is a powdered feed (containing starch and protein) by hydrothermal conditioning or without conditioning, sent into fish feed extruder machine, under the action of mechanical force, heating, pressurization, and then extrusion of the mold hole, sudden decompression, the water molecules within the rapid vaporization, so

.jpg)

APPLICATION: Aquatic feed, pet feed and pig feed industry, etc. CAPACITY: 0.03-2T/H. MAIN POWER: 3-132KW. MODEL: DGP. WhatsApp: +86 138 3838 9622. Email: enquiry@pellet-richi.com. With the rapid development of intensive aquaculture, the ecological and environmental requirements are getting higher and higher. The aquatic extruded feed processed

.jpg)

Floating Fish Feed Extruder Machine 3-4T/H. Floating Fish Feed Pellet Making Machine 4-5T/H. Floating Fish Feed Pellet Mill 6-7T/H. Fish Feed Pellet Extruder 8-10T/H. Floating Fish Pellet Machine For Sale 10-12T/H. Sinking Fish Feed Machine. Menu Toggle. Fish Feed Processing Line. Sinking Fish Feed Pellet Mill 0.6-1.2T/H.

.jpg)

8-10 T/H Fish Feed Pellet Extruder. The RCPH185*2 fish feed pellet extruder machine use a kind of general-purpose equipment to produce extruded pellets according to the demands. Multi-screw coaxial extruding, feed output is increased obviously, abrasion of wearing parts is more uniform, discharging is smoother and pellet uniformity is better.

Jun 25, 2019 · Also, the nutrients in pellets dissolve more rapidly in water, making it lower-quality fish feed than extruded feed. The extrusion process is widespread today, as it can be used to manufacture all kinds of feeds, whether buoyant, fast or slow sinking, depending on the needs of each species.

Extruded Feed: Extruded feeds often have more fat than pelleted feeds to prevent crumbling, offering more calories for hard feeders and high-performance horses. Horses may need days to adjust to extruded feed’s lighter texture. Benefits include less contamination, longer water stability without nutrient loss, higher digestibility, and

.jpg)

There are many kinds of floating fish feed mill plant— the 1-2t/h, 3-4t/h, 4-5t/h, 6-7t/h, 8-10t/h, 10-12t/h, etc., and these kinds have hundreds of customized designs in total. No matter what demands you put, we can always assemble a floating feed plant for you. Floating fish feed mill cost:80,000-3,000,000 USD.

This customer interested in SFE60C and SFE70B fish feed extruder. His demand is production capacity <250 kg/h and the pellets must float. According to customer needs, This 200kg/h fish feed making set contains: mixer machine, fish feed extruder, pellet dryer and oil sprayer. Photos: 200kg/h small fish feed making plant for Tanzania.

For fish feed pellet making, here recommend dry type fish feed machine with competitive price and capability of producing high quality feed pellets. 3.Local Raw Materials Available for Pellet Making Local raw materials for fish feed in Nigeria are available such as maize, cowpeas, groundnut, melon, potato, cassava, banana, plantain, pawpaw

.jpg)

The formulation of sinking fish feed plays a vital role in the health and growth of the fish. Organic ingredients and the right Fish Feed Pellet Size contribute to the feed’s efficiency.The process of sinking fish feed formulation is a sophisticated and critical phase that ensures the nutritional needs of different fish species are met.

Flat die type fish feed pelleting machine has a variety of aperture and compression ratio of the flat mode to choose, φ12-30mm. According to different needs, the user can choose the flat mode with different aperture and compression ratio to obtain the best technical and economic benefits. Features of flat die fish feed pellet machine