.jpg)

4 days ago · The physical feed quality is critical in enabling the feed to provide the desired nutrition and energy to the fish. Some of the common quality issues are feed integrity, non-uniformity of feed sizes, unable to attain the desired level of floatability (in case of floating feeds), dust creation from feeds, oil leakage, rancidity issues, and raw material quality.

.jpg)

Extrudinaire Pellet Extruder Real Retraction The most effective retraction technology on the market. Dual Heating Independently set temperatures & adjustable positions. Nozzle Adapters Change between nozzle types as easy as nozzle sizes. 3D Printer Interface Easy installation, smooth workflow & enhanced functionality. 300g/h Flowrate Depending on material Melt Flow Index. Up to 500°C 2x PT100

Commerical Use Automatic Chicken Feed Pellet Production Line 1-2t/h Animal feed pellet mill machine Line 100~1000KG/H 1-18t/h Ring Die Poultry Feed Machine by Electric 60-1000kg/h Flat Die Poultry Feed Machine by Electric/Diesel Engine LM 90 700-800kg/h Floating Fish Feed Machine BY Eletric Engine LM80 200-300kg/h Fish Feed Machine by Diesel Engine LM80 200-300kg/h Fish Feed Machine by

.jpg)

Role: Proteins are essential for growth, repair, and maintenance of bodily functions. Composed of amino acids, these compounds form enzymes, hormones, and other crucial molecules within the body. Sources: For fish feed, the primary sources of protein include fish meal, soybean meal, and other plant or animal-derived ingredients.

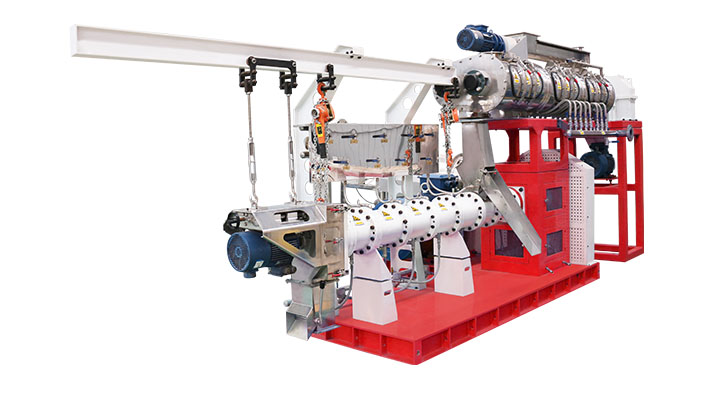

Floating Fish Feed Pellet Food Line Extruder Machines(id:8002232), View quality floating fish feed machine, fish feed pellet extruder, fish feed processing line details from Jinan Eagle Extruder Co.,Ltd storefront on EC21.com. Buy best Floating Fish Feed Pellet Food Line Extruder Machines with escrow buyer protection.

This method changes a mix of feed ingredients into dough, which then goes through a machine called an extruder. Inside the extruder, the heat and pressure cook the feed and turn it into long-lasting pellets. The Importance of Fish Feed Extrusion. Quality fish feed is crucial for the growth and health of fish.

Types of fish feed pellet machines in the Nigerian market. The fish food pellet mills currently for sale in Nigeria by our company cover a wide range of models, including small family farm-ready models to large industrial-grade fully automated lines, with outputs ranging from 40 kg per hour to 1,000 kg per hour.

.jpg)

As is well known, for pellet feed to meet the competitive demands of the market, suppliers must make sure the quality of fish feed pellets is excellent. Before pelleting, the tempering effect of materials is of great concern because it directly affects the production capacity and pellet quality of fish feed extruder machines.

Key Features to Look For. When choosing the right fish feed pellet machine, consider the machine’s efficiency, reliability, and durability. An efficient machine will consume less energy and produce more pellets per hour, which can significantly reduce your costs in the long run. Next, a reliable machine will have fewer breakdowns and require

The formulation of sinking fish feed plays a vital role in the health and growth of the fish. Organic ingredients and the right Fish Feed Pellet Size contribute to the feed’s efficiency.The process of sinking fish feed formulation is a sophisticated and critical phase that ensures the nutritional needs of different fish species are met.

.jpg)

The superiority of our Fish Feed Pellet Extruder. 1. This fish feed-making machine, made from alloy steel, has a stable structure, lower noise, small occupation, and easy operation, all of which make it popular among the farmed fish industry. 2. For a dry-type fish feed-making machine, there is no need to add additional water to the machine, so

.jpg)

May 12, 2011 · Evaluation of feed ingredient functionality plays a vital role in modern fish feed manufacturing practice. The aim of this study was to examine the extrusion behaviour of blends containing alternative protein sources from plant origin to fish meal (FM), such as wheat gluten (WG) and soy protein concentrate (SPC), and the consequences for the physical attributes of the resulting feed extrudates.

.jpg)

Operation and Support Equipment of Pellet Fish Feed Extruding Operation of pellet fish feed extruding 1.Raw materials crushing: ingredient particle size is important, and the high-quality fish feed pellet is produced by grinding the ingredients into particles with a size that is not more than 1/3 of the diameter of die hole.

.jpg)

Lima has been working in fish feed pellet making machine manufacture since 2006. Rich experience makes good product.Lima fish feed pellet machine has multi-function system and wide usage. Feeding your fishes with fish feed pellets made with Lima machine, walking on the efficient way to success!