.jpg)

Basic Functions of Single Screw Fish Feed Extruder. Taking aquatic feed fields for example, FANWAY will introduce the basic functions of this machine during the process of producing fish feed pellets. Cohesive function: In the extrusion process, feed raw material can combine closely and condense into discrete pieces.

Dec 1, 2021 · The single s crew fish feed extruder developed was tested based. on the following performance variables. They include c onstant. feed moisture, constant feed rate, and constant screw speed. while

.jpg)

Dec 1, 2017 · Significant differences in final fish body weight, weight gain, specific growth rate, and condition factor were not detected between dietary treatments after 120 days of feeding trial. Extrusion using a single screw extruder in optimal process conditions could be used to obtain fish feed based in vegetable meals and good physical properties

Twin-Screw Fish Feed Extruder. Twin-screw fish feed extruder can greatly enhance the nutrient content of fish feed that is much higher than the fish feed produced by single screw fish feed extruder. It has many advantages of long service life, high capacity, good fatigue and wear-resistant properties.

.jpg)

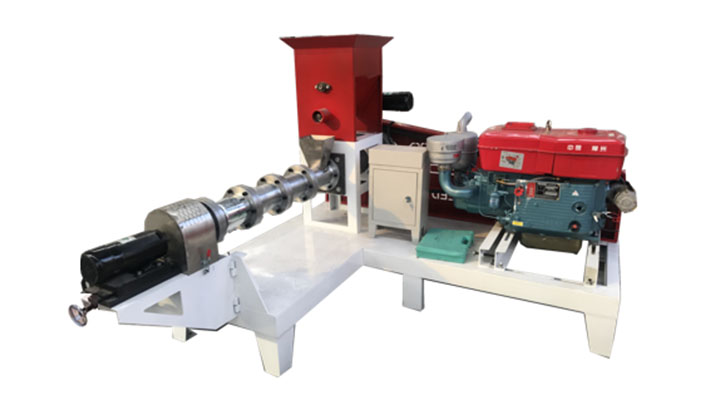

The locally developed floating fish feed extruder was evaluated for performance in terms of machine parameters such as; screw speeds (158.5, 225 and 334 rpm), die size (4, 6 and 8 mm) and moisture content of feed materials (20, 30, 40 and 50%), on specific mechanical energy requirements, expansion ratio, bulk density and pelleting efficiency were determined.

Our single-section spiral fish feed extruder was gradually eliminated from the market. And now the two-section spiral fish feed extruder is the cheapest floating fish feed pellet machine. In all respects, the two-section screw fish food extruder is also the most popular with customers.

Apr 1, 2001 · However, twin-screw extruders have become the process of choice when fat levels in recipes are above 17 percent, when fresh meats or other wet ingredients are added to recipes above the 35 percent level, or when the required pellet size is less than 1.5 mm in diameter. These extruders are also useful when ingredient flexibility is required.

1.Dry type fish feed extruder does not need the steam boiler, so the dry type fish feed pellet machine is cheaper and easier to use and operate. 2. The feed pellet made by wet type fish feed pellet machine is more smooth and with better quality because the material is ripen and mixed enough in the conditioner compared with the dry type extruder.

.jpg)

Nov 9, 2021 · 1. What is Single Screw Extruder. The single screw extruder is a machine in which an Archimedean screw continuously melts, compresses, extrudes, and forms a solid forming material in a heated barrel. Due to the simple structure, easy manufacture, high processing efficiency, and low price, the single screw extruder is widely used in food

.jpg)

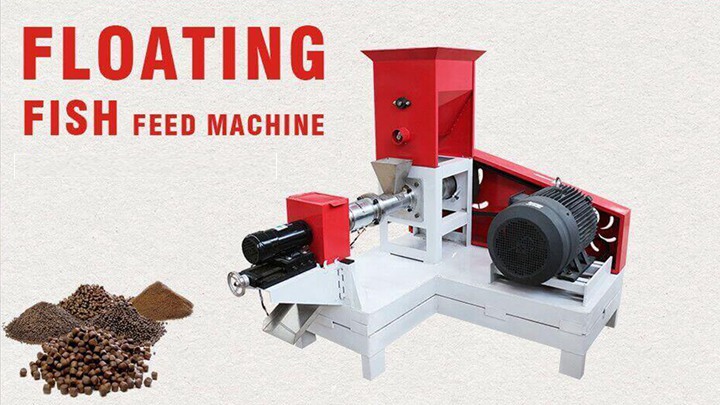

This single screw fish food extruder can produce a variety of shapes, and the product discharge port is equipped with a frequency conversion speed regulating rotary cutting device. The blade rotation speed can be adjusted arbitrarily, and the cutting speed and length can be controlled. 2. Raw materials of Floating Fish Feed Pellet Making

Oct 17, 2020 · Greater overall process flexibility. In aqua feed production, the best possible uniformity and high level of degassing decreases the chances of floating pellets when sinking aqua feed is produced. Thanks to the action of the two screws, twin-screw extrusion allows us to produce micro-pellets of up to 500 microns (0.5 mm).

Therefore it is mostly favored by owners of small scale fish farms that have lower requirement on the processing technique and output. 180-200 KG/H Dry Type Fish Feed Production Technology: Application: single screw fish feed plant is mainly applied to produce floating pellets for small- & medium-sized fish farms/ponds (If the pellets of feed

The locally developed floating fish feed extruder was evaluated for performance in terms of machine parameters such as; screw speeds (158.5, 225 and 334 rpm), die size (4, 6 and 8 mm) and moisture content of feed materials (20, 30, 40 and 50%), on specific mechanical energy requirements, expansion ratio, bulk density and pelleting efficiency were determined.

.jpg)

Performance evaluation of the fabricated floating fish feed extruding machine was done. The design of the hopper; shaft, barrel, screw and die of the machine were done using standard

.jpg)

Dec 1, 2020 · D ecember, 2020 Development of single screw extruder for the production of pineapple pomace fish feed Vol. 22, No.4 159. the angle of inclination q and t he. coefficient of f riction (Amol et al