.jpg)

Fish Feed Machine Manufacturer & Supplier. Taizy Machinery is a professional manufacturer and supplier of the fish food pellet machine, which has a history of more than ten years. After continuous innovation and upgrading, our machines are very popular in Peru, Ghana, Niger, Angola, Malaysia, Belgium, etc. Read More.

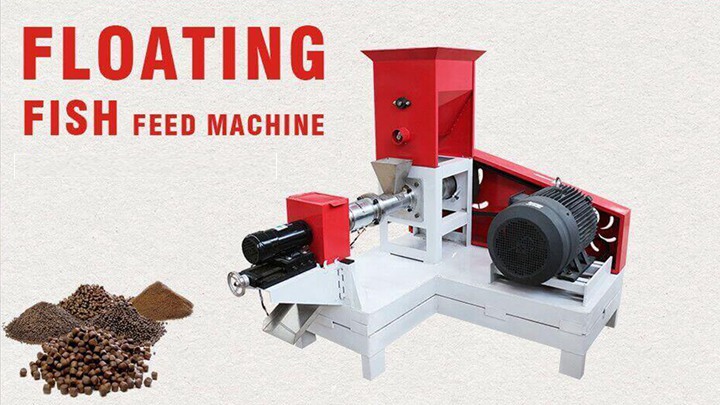

Floating Fish Feed Pellet Machine in Kenya. How it Works: These machines produce buoyant pellets that float on the water surface. Advantages: Easier monitoring of feed intake. Reduced waste and water pollution. Best For: Surface feeders like Tilapia. Price Range: $2,000 – $10,000 depending on scale and features.

The 3-4t/h floating fish feed extruder machine with good control performance can effectively guarantee the quality of floating fish extruded pellets, stable and reliable. The new generation of multi-screw coaxial continuous extrusion makes material mature more uniform and discharge smoother. Main power: 90 kw.

.jpg)

The fish feed making machine was designed to make fish feed,pet feed,and other animal feed,it was taking meat meal, fish meal, bone meal, corn meal, soybean meal, grain flour etc. as the mainly raw materials. by changing fish feed recipe, temperature, molds and others, can produces fish pellet food in different shape,color.taste.The feed pellets produced by our fish feed production line have

.jpg)

Snacks Machinery | Pet Food Machines - DEJIU. Shandong Dejiu Machinery Co.,Ltd. is a manufacturer with 15 years experience in snacks food machine,we provide snacks food machine development, manufacturing,sales and after-sales service. 0086 13256660088 info@ dejiumachinery.com. Get Price.

.jpg)

200-225 Kg/HrFloating Fish Feed Machine, 200 kg/hr. ₹ 4,40,000 Get Latest Price. Capacity. 200 kg/hr. we, “Fabon Engineering Private Limited are a reputed organization involved in Manufacture and Exporter a wide array of Organic Fertilizer, Sieving Machine, Vibro Separator, Cattle Feed Pellet Machine , Cattle Feed.

4.8/5 - (95 votes) The floating fish feed pellet making machine is a feed processing machine that can directly handle the crushing of corn, soybean meal, straw, grass, rice husk or fish meal, and bone meal. It can produce both sinking feed pellets and floating feed pellets, by changing a simple part of the machine, for underwater aquaculture

The formulation of sinking fish feed plays a vital role in the health and growth of the fish. Organic ingredients and the right Fish Feed Pellet Size contribute to the feed’s efficiency.The process of sinking fish feed formulation is a sophisticated and critical phase that ensures the nutritional needs of different fish species are met.

The initial cost of purchasing a feed pellet machine in Kenya varies significantly based on the type, features, and manufacturer. For instance, pellet machines tend to have a higher upfront cost compared to mixers due to their complexity and versatility. Always consider your production scale and specific needs to avoid overinvesting in a

.jpg)

1 Process steps to make floating fish feed. 1.1 Preparation of raw materials. 1.2 Raw material crushing stage. 1.3 Mixing and moulding. 1.4 Drying. 1.5 Seasoning. 1.6 Packaging. 2 Equipment used for fish feed pellet production.

We supply Fish Feed Production Line with different capacities. The machines include feed hammer mill, feed mixer, feed pellet extruder, feed dryer, pellet packing machine and other auxiliary machines. Our factory supply reliable fish feed pellet making machine for fish farmers. Fish feed pellet machine make quality floating and sinking fish

Key Features to Look For. When choosing the right fish feed pellet machine, consider the machine’s efficiency, reliability, and durability. An efficient machine will consume less energy and produce more pellets per hour, which can significantly reduce your costs in the long run. Next, a reliable machine will have fewer breakdowns and require

Crush cereals, miscellaneous grains, sweet potatoes, and cassava before feeding them to aid digestion. Determine the degree of crushing based on the conditions of livestock and poultry. Crush pig and cattle feed into medium particles of 1~2mm or coarser particles; grind chicken feed into titanium powder. Cut sweet potatoes and tapioca into

KSh 265,000. Three Phase Pellet Machine With 260kg Per Hour Output. This is a very high quality pellet making machine which is ideal for making chicken and fish food. KSh 220,000. 600kg/Hr Pelletizing Machine. Three phase motor Pellet machine. KSh 430,000. Extruder Machine Floating Pellet.

Small Pet Food & Aquatic Feed Pellet Plant ( 100~150kg/h) 1. Crushing Machine 2. baghouse system 3. Mixing Machine 4. Feed Extruder 5. Air Conveyor 6. Belt Dryer 7. Coating Machine. Medium Scale Pet and Fish Pellet Plant ( 200~300kg/h)