.jpg)

Price of floating fish feed extruder. The price of RICHI floating fish feed extruder is generally before 5,000-200,000USD. Richi Machinery has rich experience in fish feed extrusion. Twin-screw floating fish feed extruder equipment and wet extruder are also one of the star products produced by the company.

.jpg)

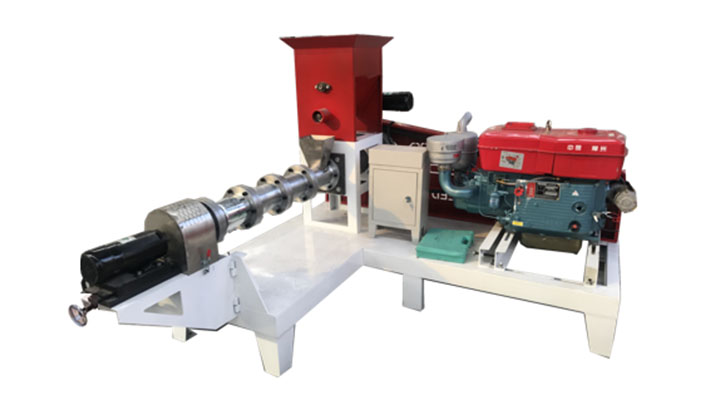

It is a crucial machine for making high-quality fish pellets and pet food. Features of Wet Type Fish Feed Making Machine. 1. This kind of fish feed extruder machine has a simple structure, wide application, and low noise. 2. It can improve the quality and floating time of the fish feed pellets. 3.

Floating fish feed extruder is a machine used in aquaculture and fish farming to produce floating fish feed pellets. These extruders are designed to process a mixture of ingredients, including fish meal, grains, oil, vitamins, and minerals, into a uniform and nutritious feed that can float on the water’s surface.

Dec 1, 2021 · The single s crew fish feed extruder developed was tested based. on the following performance variables. They include c onstant. feed moisture, constant feed rate, and constant screw speed. while

.jpg)

Aug 15, 2022 · An extruding machine for the production of floating fish feed was designed and fabricated. Performance evaluation of the fabricated floating fish feed extruding machine was done.

.jpg)

Our wet floating fish feed extruder produces 0.9-12mm pellets, suitable for pet food and animal feeds, including shrimp. We also offer a sinking feed extruder for sink pellets. The machine works with single or three-phase power. It offers capacities from 30kg/h to 5000kg/h, split between small and large scales.

RCPH120*2 floating fish feed extruder machine is the third generation of new twin-screw extruder machine developed by Richi Machinery on the basis of digesting and absorbing foreign advanced technology. Its power configuration is 90KW, and the output of processing aquatic feed is 3-4 tons per hour. It can meet the current production needs of

.jpg)

KSh 400,000. Fish Food Pellet Machine Floating Fish Feed. 40 type dry feed extruder Output: 40-50kg/h Host power: 5.5kw Cutter power: 0.4kw Feeding power: KSh 480,000. 300kg Extruder Machine ~Fish Feeds. Heavy machine for commercial users and its easy to operate. KSh 400,000. Grass Fish Feed Machines.

Investing in a floating fish feed making machine in Philippines also has economic implications. By controlling the feed production process, you can significantly reduce the operational costs and reliance on external suppliers. This self-sufficiency allows you to dictate quality and pricing, making your aquaculture business more profitable and

Fish Feed Extruder Machine . Our fish feed Extruder Machine: "Saibainuo Machinery" systems efficiently produce high-energy feed, with a precise balance of proteins, oils, and carbohydrates, processed for optimum digestibility with reduced waste. Its systems produce the right formula that turns “feed into flesh” and is particularly suited

There are two types of fish feed extruding machine. One is dry type fish feed machine, the other is wet type fish feed machine. Learn about the main structure of our flaoting fish feed extrduder machine for sale: lt has enough space for large quantities of feed to ensure a stable supply to the extruder. To keep the flow stable safe for the extrudin See full list onLimamach.com The feed drifts down the feeder as pressure on the feed creates a uniform input. The material is squeezed with more pressure and friction. You can use electricity in the compression chamber by connecting the electric sheet to increase the heat for an easier extrusion. This chamber is suitable for softening the hardest fish feed raw materials making... See full list onLimamach.com Make Expanded Fish Feed Pellets Extruded fish feed is designed according to your specific feed portion and style. With the increased cost of feed and the demand for healthier fish, extruded fish feed is enormously beneficial. 1. More palatable: With the pressure applied at extrusion, the feed is made softer and digestible. The feed also retains all... See full list onLimamach.com

The fish feed extrusion process consists of several steps: Ingredient Selection: The first step involves sourcing the best quality raw materials like fishmeal, grains, and oils. Grinding: The ingredients are then finely ground to ensure uniformity. Mixing: Ground ingredients are mixed together in a feed mixer machine.

.jpg)

Production Line Advantages. Features of floating fish feed Production Line: 1) Design: Developed by 3D software, analog simulation, and it has been tested by a computer automatically, in order to ensure the accuracy of the design requirements. 2) Concept: Modular function, humanized menu system, and various applications are always our pursuits.

Clextral extrusion systems efficiently produce high-energy feed with a precise balance of proteins, oils and carbohydrates, processed for optimum digestibility. Extruded feeds are produced to match fish feeding habits (floating, neutral buoyancy or sinking) to energize feeding and reduce waste. We offer an output range from 25 to over 34,000 kg

.jpg)

The export of the fish feed pellet extruder machine to Ghana in January 2019 was a noteworthy event for us, reinforcing our commitment to quality and customer satisfaction. The machine, with its 300kg/h production capacity and electricity power, is an answer to the growing demands of the fish farming community in Ghana.