For storage purposes, the moisture content of pelleted feed is required to be no more than 12 to 12.5 percent. Out-spraying. Spraying grease on the surface of pellets is called pellet greasing. Pellet coating can not only improve the nutritional value of feed, but also improve the palatability of feed. Cooling.

.jpg)

Apr 1, 2004 · Fig. 1: Zones of a single-screw extruder. Fig. 2: Protein molten phase and swollen starch granules. Fig. 1 is a schematic view of a single-screw extruder with different zones. The first section is the feed zone, where the formula mix is added to the extruder. This zone is characterized by deep channel screws designed to convey.

6. Advantages of floating fish feed. It is very crucial for fish farmers to ensure that the fish get all the food they require, both in terms of quantity and quality. In fact, feed accounts for almost 60% of the total production cost. So, farmers need to spend a lot of time and effort in determining the right feed.

.jpg)

The price of 1 ton floating fish feed making line is usually 30,000-150,000 USD. According to your needs, we can also provide custom design services. Pls send me a proforma incoice include transport price for 2-3t/h floating fish feed production line. The 2-3t/h floating fish feed line cost is USD 80,000-500,000.

.jpg)

The fish feed extrusion process consists of several steps: Ingredient Selection: The first step involves sourcing the best quality raw materials like fishmeal, grains, and oils. Grinding: The ingredients are then finely ground to ensure uniformity. Mixing: Ground ingredients are mixed together in a feed mixer machine.

.jpg)

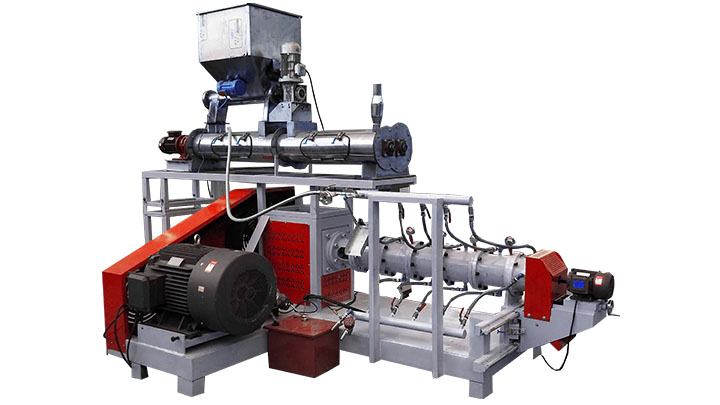

RCPH120*2 floating fish feed extruder machine is the third generation of new twin-screw extruder machine developed by Richi Machinery on the basis of digesting and absorbing foreign advanced technology. Its power configuration is 90KW, and the output of processing aquatic feed is 3-4 tons per hour. It can meet the current production needs of

How a Complete Floating Fish Feed Production Line Works.Click on the TIMESTAMPS below to easily navigate through the video.0:00 Introduction to LIMA Fish Fe

May 12, 2023 · A floating fish feed production line is an advanced and efficient system used for manufacturing high-quality and nutritious fish feed pellets. It includes several stages, such as handling and processing raw materials, extrusion, drying/cooling/packaging of final products and more. One of the key advantages of floating fish feed production lines

The production of aquatic feed often uses a horizontal double-shaft paddle high-efficiency feed mixing machine or a double-shaft double-screw mixer. The former has a mixing time of 2 to 3 minutes and a CV of less than 5%; the latter has a mixing time of 5 to 6 minutes and a CV of 5% to 6%. . 4-5T/H floating fish feed plant often uses two mixing

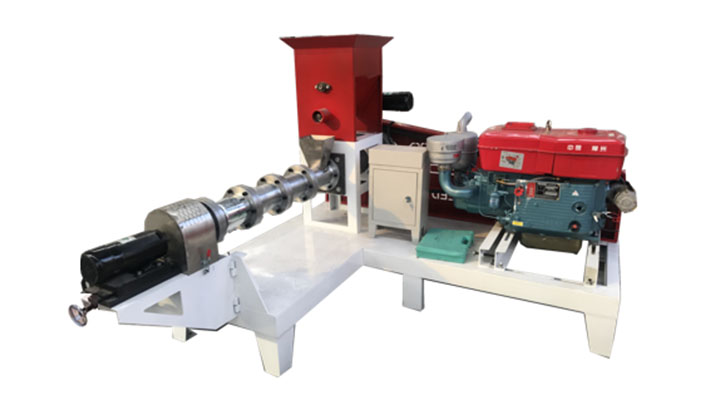

Extruding Fish Feed Pellets Production Line at Low Cost. Fish feed production line, designed with feed extruder machine, can produce floating fish feed pellets, semi-sinking fish feed pellets and sinking fish feed pellets through a series of production processes, including micro crushing of raw materials, ingredients mixing, extruding, cutting

Extrusion for the production of Fish Feed. Extrusion is a key process in making fish feed, especially for fish that need high energy and easy digestion. With extrusion, we can adjust the bulk density to create feeds suitable for different fish. Some fish prefer floating pellets, while others need pellets that stay stable in the water for a long

.jpg)

Role: Proteins are essential for growth, repair, and maintenance of bodily functions. Composed of amino acids, these compounds form enzymes, hormones, and other crucial molecules within the body. Sources: For fish feed, the primary sources of protein include fish meal, soybean meal, and other plant or animal-derived ingredients.

.jpg)

Jun 23, 2023 · Floating fish feed contains a range of ingredients that provide the necessary nutrients for fish. The primary ingredients used in the production of fish feed include: a) Fishmeal: A high-quality protein source derived from processed fish, which serves as the primary protein component in fish feed. b) Fish Oil: A rich source of essential omega-3

Floating fish feed pellet production process plant is designed for making commercial pellets from corn, maize, grass, grains, protein, molasses and so on with capacity of 100-2000kg/h. Fish pellet machine can make 0.3-15mm according to customer's requirements.

Apr 24, 2024 · Offers a diverse range of floating fish feed making machines catering to different production capacities and requirements. Specializes in compact machines suitable for small to medium-scale aquaculture operations. Incorporates cutting-edge technology for enhanced efficiency and productivity.