SKIOLD feed milling equipment makes up complete, customised solutions for grinding and proportioning feed. This concerns all feed mill machines for the modern feed mill - equipment for conveying, cleaning, proportioning, grinding, mixing, pelleting, ready feed handling, and much more for animal feed. Feed milling that meet your needs

Production Output Range: 1~1000,000 tons/year.Lima Machinery supplied poultry and cattle feed plant adopts module design which can realize customized feed processing plant. Meanwhile, as an experienced feed mill machine factory, we can also help you make the best business plan for setting up your own animal feed pellet plant, like mini poultry

Feb 28, 2016 · Soluble grit (shown here) is a calcium supplement which helps promote strong eggshells. Commercial feeds should contain enough calcium, but you can serve soluble grit in the same way as flint grit and the chickens will take what they need. Mixed grit is a combination of the two types and handy to keep in stock. 6.

MIX POWER: 4 KW, MILL POWER: 15 KW. 0.6. HT-V 2.0. 2. 2.4 x 1.56 x 2.8. MIX POWER: 5.5 KW, MILL POWER: 15 KW. 0.75. Horizontal Mixers. Stationary horizontal feed mixer includes a mixing box, a mixing device and a support frame, a mixing device is provided in the mixing box, the mixing box includes a box body, a box cover, a bearing sleeve, a

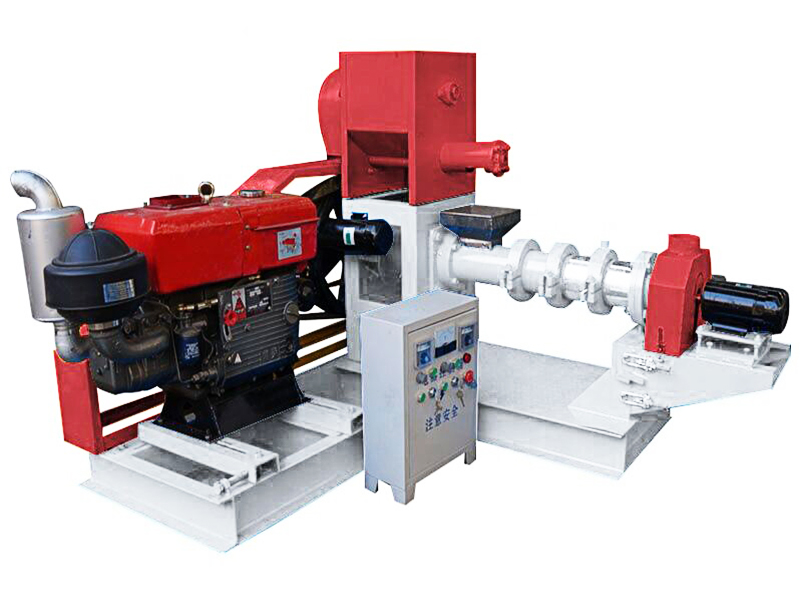

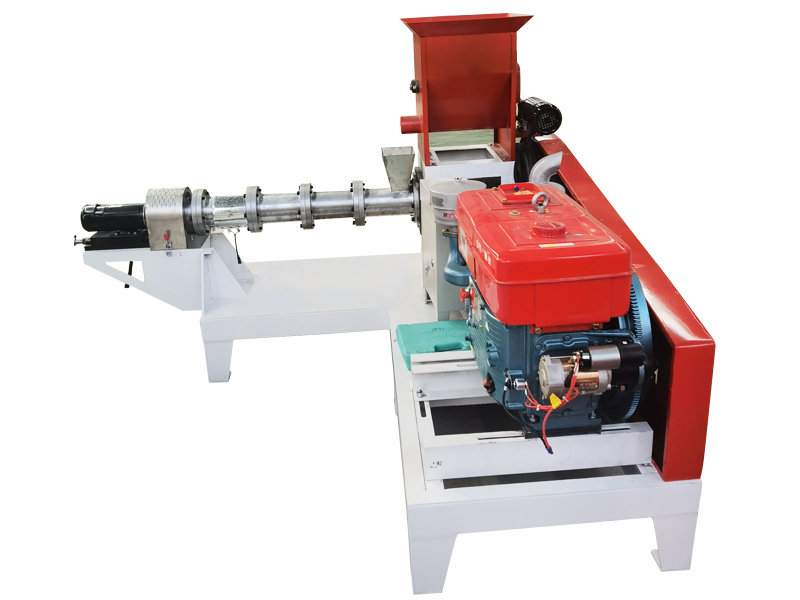

This one of our small feed mill equipment based on flat die design, featured of small size, and high chicken feed production output. Flat die chicken feed mill is more suitable for make your own feed pellets at home or on farm. Basic Feed Milling Process: Raw Feed → Mash Feed → Pelleted Feed. There are different types of small animal feed pellet mill for sale with diesel engine, electric engine and gasoline engine.

Sample project: 2-4TPH Animal Feed Mill Plant for Cattle and Poultry. 2. Equipment Selection:High Quality Feed Pellet Mixing Machine. Mixing is a kind of operation in which various feed ingredients are mixed with each other under the action of external force after metering and proportioning to make them evenly distributed.

feed mill with hammer mill. Productivity: 2 t/h - 5 t/h. Capacity 2t/h: power 25-40 kWt; air consumption for aspiration 2100 cub.m/h; overall dimensions: 18200 x 5000 x 8000 mm Capacity 5t/h: power 72 kWt; air consumption for aspiration 2100 cub.m/h; overall dimensions: 15000 x 10000 x 16000 mm.

Dec 01, 2012 · Grinding up the feed so the chickens (especially the smaller chicks) can more easily ingest and digest it. There are plenty of grinders out there, but most of them are this type: the huge PTO-driven mixer-grinders for large-scale operations. At a cost of $3000 on up (not including the tractor to power them) this is not a viable option for our farm.

The experience and practical knowledge provides unbiased opinion on the equipment that best meets the requirements. AFS offers a wide range of specialized process equipment for the industry. Square bolted steel bin systems. Belt, drag chain and screw conveyors. Belt, drag chain and screw conveyors. Distributors, slide gates and diverter valves.

The chicken feed making machine is an ideal equipment for chicken broiler layer breeding. It is of great significance for feed maturation, increase nutrition, improve absorption, convenient storage and transportation, adapt to the chewing function of animals, and high-yield and high-efficiency livestock breeding.

Feed grinder mixer machine is a poultry feed mill equipment, mainly used to produce powder mixed feed, suitable for large and small farms, feed processing plants, etc. Poultry feed mill equipment is suitable for animal and poultry farms, such as small and large chicken farms, pig farms, etc. The mixer can be used for grinding and mixing various livestock, poultry and animal feeds such as chickens, pigs, sheep, fish, rabbits, etc.

When it comes to setting up your own mill you should be aware that they must adhere to strict sanitation standards in order to prevent disease outbreaks. Your state may also require you to obtain a license before starting operations. To set up a feed mill you will need to purchase equipment such as grinder mixers, augers, conveyors, bins, etc.

Used Feed Handling Equipment for sale. Buy and sell used Feed Handling Equipment from any and all manufacturers, including Custom Built, Feed-miser, Haybuster, Rachar Steel and more. From Bale Processor and Feed Grinder Mixer to Feed Grinder and Feed Mixer, you can be sure to find exactly what you need. If you are looking for a used Feed

1 ton/h feed milling machine. $10,000~$20,000. 3 ton/h animal feed process company (both making mash feed and pelleted feed) $60,000. 5 ton/h cattle feed process line. $70,000~$80,000. 10 ton/h feed manufacturing plant. over $100,000. Note: When it comes to project investment cost, you need to consider raw materials, workshop rent, equipment

Oct 11, 2018 · Basic feed mill equipment operations for making animal or poultry feed pellets include Raw Material Receiving, Grinding, Batching, Mixing, Pelleting, Cooling, Sifting, Packaging and Warehousing. Raw material receiving. Feed mills are usually equipped to receive both rail and truck delivery of grains and other ingredients.