100% Original Grass Pellet Mill - Professional manufacturer of Pellet Mill Machine for Feed industry – Zhengyi Product Description Industrial – use Ring Die Feed Pellet Mill Introduction Ring Die Animal Feed Pellet Mill adopts mature technology to make high-quality animal feed pellets for chicken, cattle, horse, duck, etc. with large

2.The chicken feed pelleting machine has a compact structure, small occupation area, low energy consumption,and high efficiency. 3.Large capacity, suitable for commercial chicken feed making plant. 4.Easy maintenance, safe and reliable, less investment and quick effect.

Factory wholesale Poultry Feed Mill Design - Professional manufacturer of Pellet Mill Machine for Feed industry – Zhengyi Product Description Industrial – use Ring Die Feed Pellet Mill Introduction Ring Die Animal Feed Pellet Mill adopts mature technology to make high-quality animal feed pellets for chicken, cattle, horse, duck, etc. with

3. Equipment and Personnel. The investment animal feed production business plan will focus on the plant and equipment as the biggest expenditure in the initial costs, you need to invest in high quality equipment to achieve quality feeds. You could also invest in customized equipment for your needs which will call for more investment, use expert

A variety of poultry feeds (mash feed, crumble feed, pellet feed) is produced for different purposes as a single feed cannot fulfill all nutritious requirements of the birds. The poultry feed mill plant makes and supplies food products for chickens, geese, ducks and some of the domestic birds. In earlier days, forage was the most common poultry

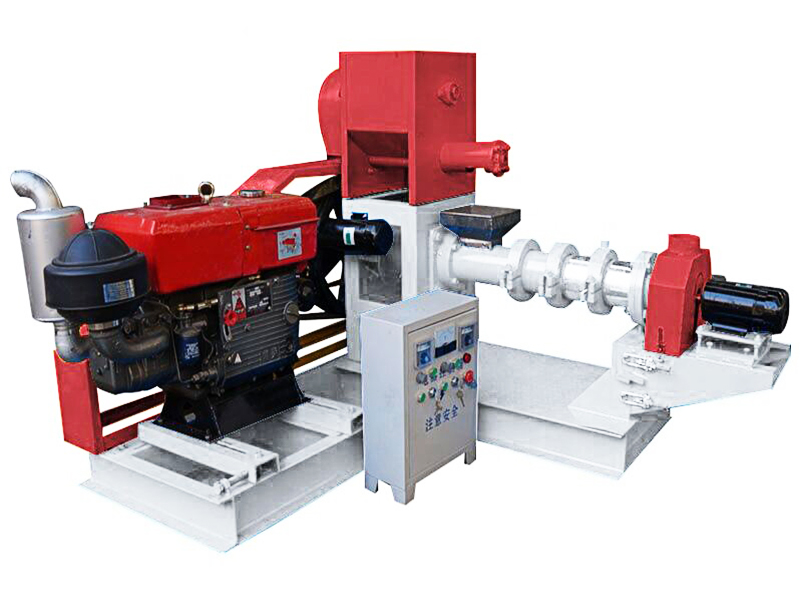

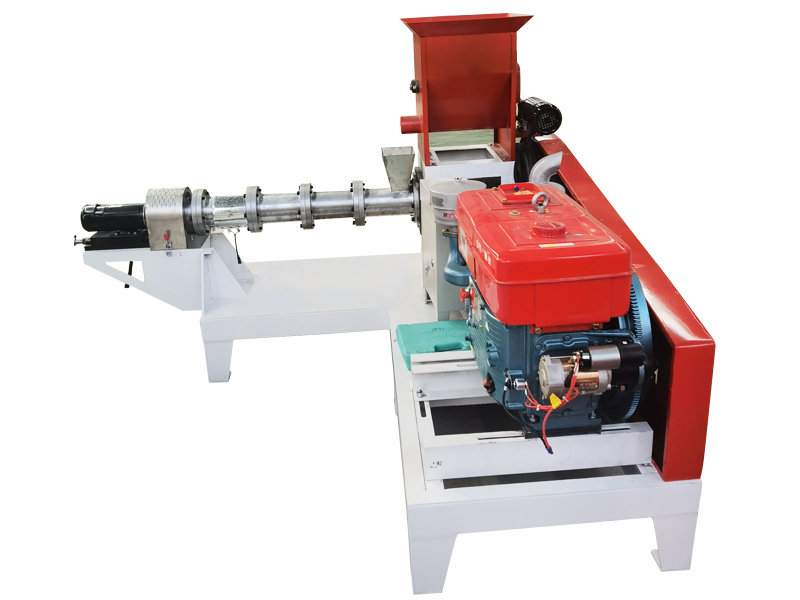

Types: 1) Crusher—-To crush the raw material into powder. 2) Mixer ——-To make all kinds of powder mixed evenly. 3) Extruder—-To make many kinds of feed pellet. Such as fish feed, pet feed. 4) Dryer——–To remove the extra moisture of the pellet. 5) Cooler—— To reduce the temperature of the pellet after dring. 6) Packaging

Flat die poultry pellet mill production machine mainly suitable for medium-and small-scale farming professional households and other processing of various livestock and poultry and aquatic pellet feed can reduce the cost of aquaculture.Feed machine can be used for raising rabbits, chickens, ducks, geese, fish, pigs, cattle, sheep, aquatic products and so on.

Chicken Feed Mill Machines Ordered by Bangladesh Client. In 2020, a new customer from Bangladesh ordered a complete animal feed production line fromLima Machinery. He planned to buy this poultry feed mill machine to produce nutritional complete formula chicken feed in his own

Feb 21, 2013 · Feb, 21-27, 2013, KMEC will attend 17th ACITF to exhibit complete feed mill plant and

Feed Mill Parameters. Type: ZLSP 150B. Driven by: Electric Motor. Power: Three phase 4. Output: 90-120 kg/h. Weight: 95/110 kg. Package Size: 800x450x700. Application: Widely used for making chicken, duck, fish, cattle, pig and other kinds of poultry & livestock animal feed pellets.Lima Machinery is an experienced manufacturer of feed mill

The small cattle feed plant cost is closely related to the production output, process design and equipments included in the plant. The equipment cost is about 10,000 ~ 17,000 USD. Jsut feel free to get in touch with us for FREE Quotation List, and get other details of our cattle feed making machine!

Nov 11, 2021 · Mid-range machines cost approximately $2000 to $3500, and large-scale feed mill equipment for sale can cost a minimum of $5000. Although the prices of some poultry feed mill machinery may seem overwhelming, investing in such a cost-effective machine will help you to save money in the long run. It will also ensure your poultry eats healthily.

BEST poultry equipment introduction: Automatic drinking line Automatic feeding line 10-12 birds per square meter Reduce labor cost and disease spread Star Liu Tel & Whatsapp: +86 18830120195 E

Compared with the same model in the chicken feed making machine industry, the small chicken/poultry feed pellet mill manufactured byLima Machinery has high output, low energy consumption, and the production reached 15-20 kg/kw, while other manufacturers generally reach to 10 kg/kw, unit production energy consumption is generally in 0.05-0.06

Rotary Drum Mixer Machine. rotary drum mixer machine introduction Waist rotary drum mixer machine is a new type made of stainless steel, high-efficiency, fine-container rotary, stirring-type mixing equipment. It is used for uniform mixing of various powdery and granular materials. It has a high degree of mixing, and it can also achieve better