Save money on feed processing machines when you shop for fish food extruding atLima.com. Discover permanently low prices when you buy direct from Chinese wholesalers.

.jpg)

5 Extrusion. Food extrusion is a high temperature short time (HTST) process which has become the most widely used technique for the production of snacks, breakfast cereals and texturized vegetable protein (Das & Bhattacharya, 2019, Samyor, Deka, & Das, 2018 ). It is the most popular and highly utilized technology for rice fortification.

Food extrusion involves using high extrusion temperatures to enable the denaturation of proteins. It’s essential that you have both the raw materials and the extrusion technology on hand to complete the process. The BCH Extrusion system forces a mixed (and often cooked) mass through a die that’s engineered to a desired shape, which is why

Many developments are available as upgrades for existing machinery – often, original machine performance can be exceeded, and service life given a worthwhile extension. UK bpltd@bakerperkins.com. US bpinc@bakerperkins.com. UK +44 1733 283000. US +1 616 784 3111. 19 to 21. Baker Perkins are a leading global food extruder manufacturers and have

.jpg)

3) Precision: Precise food manufacturing technology and material selection that ensures cable life is superior to extruder products, to minimize screw and barrel wear. 4) Energy-saving and high efficiency, cross circulation, independent air chamber, upper heating box, automatic slag cleaning, fully open insulation door, easy to clean, easy to

.jpg)

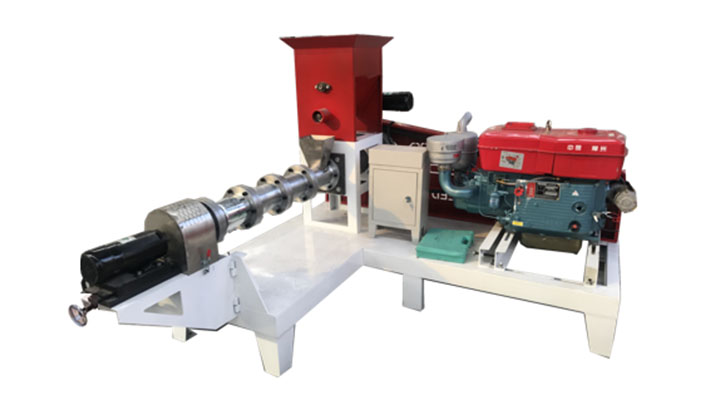

11/10/2018 · The capability of an extruder enhances the feed manufacturer’s flexibility to produce fish feed pellets for shrimp, crab, eel, catfish, carp, frogs and etc.. 2.High starch gelatinization Feed material goes through the processing of HTST, starch gelatinization degree increase can reach 80-99% for aquatic animals easily digest.

Jul 1, 2017 · IFT is a forum for passionate food professionals and students to collaborate, learn, and contribute all with the goal of inspiring and transforming collective knowledge into innovative solutions for the benefit of all people around the world. Our Community Join Us. 11,000+. 90+.

Save money on feed processing machines when you shop for fish food pellet extruding machine atLima.com. Discover permanently low prices when you buy direct from Chinese wholesalers.

.jpg)

Aug 15, 2022 · Die size variation also shows high impact on the machine performance, showing highest efficiency of 83% at 10 mm die size and 250 rpm while the floatation rate was 98% at 6mm die size.

2 days ago · In the 1930s, extrusion technology was adopted by the food industry. The extrusion application in foods started in the 1930s with the production of breakfast cereal pellets and dry pasta on single screw extruders (SSE). Dry pet foods were manufactured with extruders in the 1950s.

.jpg)

Desktop Extruded For Food Pellet Machine Extruding Fish Food Floating Fish Feed Pellet Making Machine Extruder No reviews yet Shandong Light M&e Co., Ltd. Custom manufacturer 18 yrs CN

119kw. 90kw. 400~600kg/h. 5200×1300×2500mm. III.More Details of Twin Screw Extruder in Food Industry. Feeding Unit. Function: To introduce materials into the extruder at a constant speed. Drive Unit. This is composed big drive motor and heavy-duty gearbox to supply the continuous, stable and strong power to the twin screw.

.jpg)

Uzwil. 9240. Switzerland. Contact us. Bühler’s extrusion solutions for human food, pet food and aqua feed manufacturing include weighing, dosing and grinding, cooking and shaping, drying and coating. Global services include process engineering, R&D and local customer service centers.

.jpg)

Welcome to Jinan Eagle Food Machinery Co.,ltd, the leading provider of advanced extrusion solutions tailored for the food processing industry. Specializing in high-quality, efficient machinery, we offer a comprehensive range of products including dog food plant extruders, snack food machines, modified starch machines, bread crumbs manufacturing plants, and soya protein production equipment.

.jpg)

Food extrusion and design products for successful, laboratory-scale food development. Food extrusion is an established and highly versatile technique for the production of food, feed, nutritional additives and flavors. It enables a continuous and cost-effective means of production, and its precise control ensures a high and constant product