.jpg)

3 parts mechanism. Feeding section: This section, with a larger pitch, mainly conveys and compresses materials to fill the spiral groove with feed. Compression section: The spiral groove becomes shallower along the pushing direction to compress the material.

.jpg)

Nov 13, 2023 · In contrast, the majority of the feeds used in animal agriculture or for livestock are processed in a feed pellet mill, since pellet mills have a higher production rate than extruders with the same capacity of drive motor. This makes the pelleted feeds less expensive than extruded feeds.

.jpg)

To dry the fish feed pellets coming from the extruder: 5: Cooling: Contraflow Cooler: To cool the fish feed pellets, the fish feed pellets could be stored for a long time. 6: Flavoring: Rotary flavoring machine : To seasoning the fish feed, spray oil and other liquid additives on the surface of fish feed pellets, make the feed more delicious. 7

.jpg)

Fish feed pellets produced by our pellet mill have homogenous nutritional value after the uniform mixture and extrusion process, increasing gelatinization and digestibility of feed pellet, so that each fish can absorb a well-balanced diet, also saving feed pellets and lowering the fish farming cost.

.jpg)

Huatuo commercial fish pellet poultry feed manufacturing mill machine: N61,000 – N82,000; HJ screw fish pellet extruder/small floating fish feed pellet extruder machine: N594,000 – N635,000; Share Chicken Feed Pallet Making Machine Fish Feed Extruder: N553,000 – N602,000

Organic ingredients and the right Fish Feed Pellet Size contribute to the feed’s efficiency.The process of sinking fish feed formulation is a sophisticated and critical phase that ensures the nutritional needs of different fish species are met.

.jpg)

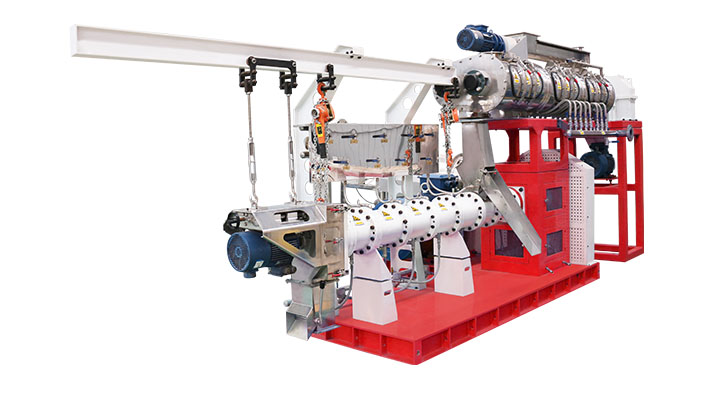

Introducing our state-of-the-art Fish Feed Extruder, designed to elevate your fish feed production process to new heights. Our extruder offers unparalleled e

.jpg)

1 day ago · Formulated fish feeds are the most cost-effective way to provide a balanced nutrition for aquacultured fishes. This factsheet compares the pellet mill and

.jpg)

As a manufacturer of extruders for the production of animal feed, in particular dog food, cat food and fish feed, as well as food, we give the extruder market a boost. The highest level of engineering and professional further development of our existing extruder make operation even easier than before.

In recent years, the Kenyan government and owners of the fishery have been committed to increasing their exporting volume and farmed fish production for more profits, especially since the administrative vice minister of Kenya’s Department of Fisheries said that Kenya had already got the permission from EU to export cultured fishes in 2015, erenow Kenya mainly exported fishes from natural

.jpg)

Floating Fish Feed Extruder Introduction Fish feed extruder is primarily used for producing high-quality puffing pellets for fishes like catfish, carp, tilapia, salmon, trout, aquarium fish, etc. A wide range of raw materials containing cereals, fish meal, soybean, other vegetable protein meals, fats, and oils can be processed into pellets by a

.jpg)

The floating fish feed extruder could produce the sink fish feed and floating fish feed, according to different fish feed formular. The floating fish feed extruder allows for precise control over the pellet’s size, shape, density, and nutritional composition, ensuring that the fish receive a balanced and high-quality diet for optimal growth

According to whether to add steam or water, the fish feed extruder machine can be divided into two types: dry type fish feed extruder and wet type; according to the extrusion method, the floating fish feed extruder machine can be divided into two types: single screw fish feed extruder machine for fish and double shaft floating fish feed extruder machine.

Introduction of Dry-type Fish Feed Machine. Dry-type fish feed extruder is adopted to process various kinds of grains into high-grade aquatic feed pellets for fish, catfish, shrimps, crab, etc. Final pellets produced by fish feed extruders have a unique shape, good taste, and balanced nutrition.

.jpg)

For large factories however, the wet type feed extruder that has a conditioner will be able to produce in large quantity, a high quality fish feed pellet. Get Fish Feed Extruder Price! 4. Drying Fish feed pellets from pellet making machine need to lower high moisture and temperature. So mesh belt dryer should be equipped in the production line