.jpg)

Partner with a Leading PVC Twin Screw Extruder Manufacturer At TwinScrew, we are committed to providing our customers with the expertise and equipment they need to achieve exceptional output quality with the PVC Twin Screw Extruders. Our team of experienced engineers and technicians can guide you in selecting the right extruder, optimizing

Save money on feed processing machines when you shop for industrial extruders atLima.com. Discover permanently low prices when you buy direct from Chinese wholesalers.

.jpg)

Apr 25, 2018 · This track record combined with high output rates and a rapid return on investment make Davis-Standard extruders the workhorses of the industry. From single and twin screw extruders to specialty, reclaim, medical and elastomer extruders, the depth and availability of our extruder offering is what makes Davis-Standard the global extrusion leader.

.jpg)

TSEs are starve fed, with the output rate determined by the feeder(s), which meter materials into the process section. The TSE screw rpm is independent from the feed rate and is used to optimize compounding efficiencies. HSEI twin screw extruders utilize segmented screws that are assembled on high torque shafts. Barrels

Mar 4, 2006 · For example: A 40-mm twin-screw extruder is processing a mineral-filled PP at 160 kg/hr, running at 400 rpm with a %torque of 68%. The machine has a 56 kW (approx. 75 hp) motor and a maximum possible screw rpm of 600. kW (applied)=56 kW x .68 x 400/600 x .97=.154 kW per kg/hr.

.jpg)

High throughput: Generally twin screw extruders have higher output capacities than single screw ones thus increasing overall productivity. Robustness: Twin screw extruders are made strong and with tough features therefore can last for many years under normal conditions which makes them cheap in the long run for most industries.

.jpg)

Clextral systems can easily produce high energy feed, allowing a delicate balance of proteins, oils and carbohydrates, processed for total digestibility with no waste. It’s the right formula for high quality products that “turn feed into flesh.” Output range from 25 to 30,000 kg/h. Thanks to twin screw extrusion, high quality

.jpg)

Co-rotating, intermeshing twin screw extruder: The co-rotating twin screw extruder is the most prevalent continuous mixing device in the world. Typical applications include masterbatch and compounding processes in which fillers, pigments, dyes and additives are homogeneously mixed into the plastic matrix.

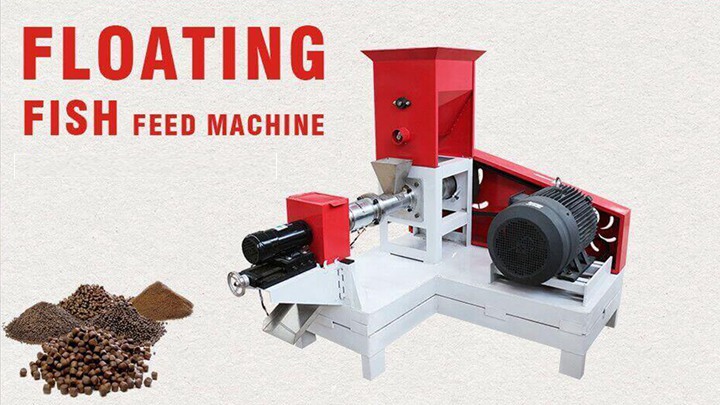

Floating fish feed extruder machine twin screw extruder $150,000.00. Min Order: 1 set. High Output Industrial Twin-Screw Fish Feed Extruder $40,000.00 - $45,050.00.

.jpg)

Compared with single-screw fish feed extruder, our twin-screw extruder solves many shortcomings, such as: less in production, lack of expansion efficiency, difficulty in cleaning, limit of adding nutrient content, quick wearing of screw, high cost of accessories, etc. Twin-screw fish feed extruder could effectively kill the Escherichia col

.jpg)

High quality Industrial 220V Twin Screw 100kg/Hr Fish Feed Extruder from China, China's leading 100kg/Hr Fish Feed Extruder product, with strict quality control LG Fish Feed Extruder factories, producing high quality SS304 Fish Food Pellet Machine products.

.jpg)

May 24, 2018 - Large capacity twin-screw fish feed plant is a new type of high output production line using double screw extruder. Double screw fish feed extruder is the core equipment in this production line that can process various shapes of floating fish feed.

.jpg)

Twin Screw Fish Feed Extruder. Pellet size : 1mm~10mm. Application : Dog,cat,fish,tilapia, shrimps, gold-fish, tropical fish,etc. Advantages: Energy saving and environmental protection, fully automatic high output. Contact Now.

Apr 10, 2024 · Function: Fully automatic production of floating fish feed Output: 2 tons per hour Shipping method: Shipping Main equipment: mixer, feed extruder, cooler, dryer, seasoning machine, packaging machine

2023-2-5·Twin screw fish feed extruder, also called floating fish feed machine, is widely used for produce high-grade aquatic feed pellets for fish, catfish, shrimp, crab, lobsters, etc.We have two types of fish feed extruder, dry type and wet type model fish feed machine, through feeding materials, extruding,Forming,Filling and cutting, drying, oil