.jpg)

A pellet extruder is basically a part that combines a pellet melter and a pushing mechanism in one device. In this way they replace the extruder-melter assembly in our printer, so we must replace both elements by one of these pellet extruders. The new extruder uses pellets instead of filament to work.

Premium dog food plant solutions. We provide complete solutions to produce dog food meeting all the relevant trends in the industry, such as fresh meat inclusion, grain-free formulations and alternative protein sources. With the matched set of our extruder and dryer you can realize benefits in flexibility, raw material usage, and consistency.

.jpg)

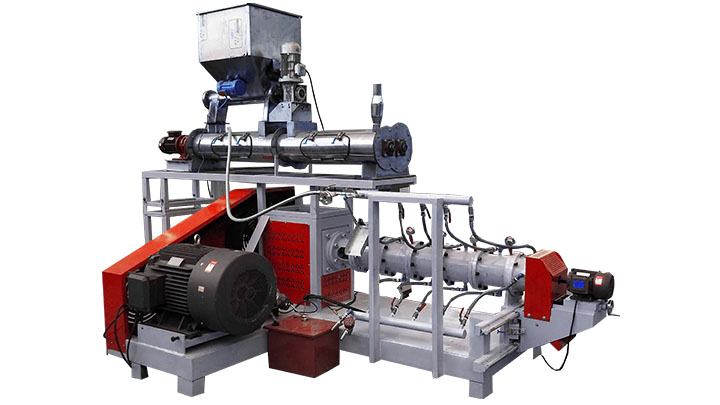

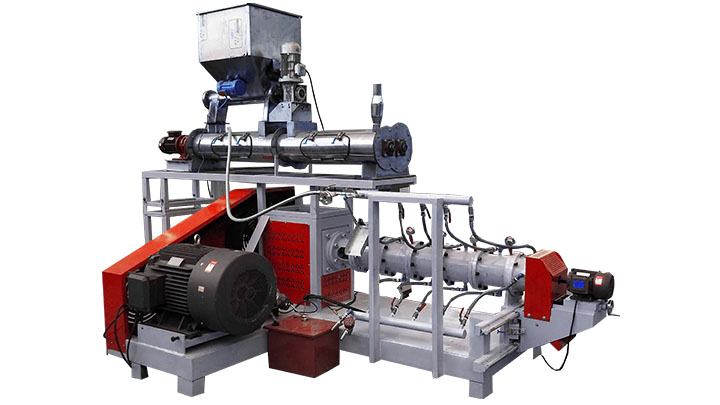

Equipped with torque limiter, ensures the gearbox running smoothly and more reliable. SJPS Series Twin-Screw Extruder. Highly efficient extruder for pet food, especially for high fresh meat formulations. Easy operation. PLC and touch screen for convenient control; by-pass provided for avoiding blockage; easy operation, precise and reliable.

Nov 7, 2016 · Whatever else is on their dockets, extrusion experts all agree that flexibility will be vital for the pet food industry success going forward. “Flexibility is our key focus for 2017,” said Funk. “We see this as an absolute necessity for our industrial partners, as the pet food market trends continue to expand exponentially.

.jpg)

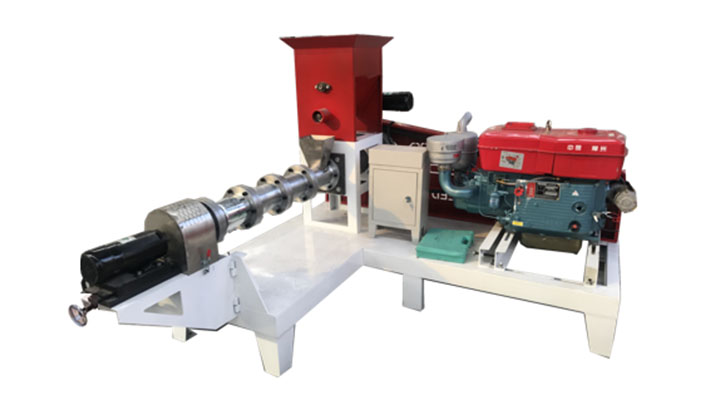

Pelletization solutions with afish pellet mill atLima. Explore high performancefish pellet extruder options for small-scale and industrial production, with fixed and mobile units.

.jpg)

Visit us at Fakuma 2024, 15-19 October, Friedrichshafen, Germany. Direct3D manufactures and delivers small, lightweight and cost-effective Pellet Extruders and 3D Printers. Wider selection of materials, including very soft TPEs. Higher productivity, ideal for mid size parts.

Apr 5, 2024 · The shift towards pelletized plastic in 3D printing, championed by Greenboy3D's innovative extruder, marks a significant stride towards sustainability and cost efficiency. By utilizing pellets instead of traditional spooled plastic, users can expect a dramatic reduction in printing costs. This cost-effectiveness stems from the lower price of

With Wenger, you make nutricious and delicious products that pets (of all sizes) love to eat. And eat. And eat. Through careful testing and extensive research, our world-class team helps you develop premium foods and treats, and the processes to produce them at scale. Pet food producers globally trust Wenger for extrusion cooking and drying

![<h3>[INTERVIEW] Dyze Design launches the Pulsar™ Atom, a new high </h3>](/wp-content/themes/lima/load/52/Floating fish feed pellet machine (14).jpg)

May 29, 2024 · Time is running out! Nominate now for the 3D Printing Industry Awards 2023. Montreal-based high-performance 3D printer extruder manufacturer Dyze Design has launched the Pulsar™ Atom, a new

The robot extruders are ideal to turn your existing robot- or CNC system in a large scale 3D printer. The extruders are designed to process fiber-filled thermoplastic pellets, a cost-effective material that offers high performance and quality. The extruders process virtually all short-fiber reinforced thermoplastic composites, making them

.jpg)

Save costs. Pulsar™ is a state-of-the-art large-scale and high flow plastic pellet extruder. It was designed with one purpose in mind: 3D printing of parts of one m³ and more as quickly and as cost-effective as possible. Pulsar™ is compatible with any large-scale 3d printer or even robotic arms and is able to output as much as 500mm³/s (2

.jpg)

Mar 6, 2024 · The Best Pellet 3D Printers in 2024. by Ile Kauppila. Updated Mar 6, 2024. Cut your material costs by more than 60% by printing with pellets, granules, and recycled plastics instead of filament. Check out the top pellet 3D printers on the market. Advertisement.

.jpg)

Experienced engineers are on hand to assist with extruder customization, die design, system controls and the selection of associated extrusion equipment. Question? CALL US. Pet Food Extruders Manufacturer - Diamond America Knowledge Experience Top quality extruders for pet food processing ☎ 330.535.3330.

.jpg)

The Mahor V4 extruder is capable of depositing 200 g of plastic per hour, and achieving melting temperatures of 30-300 ºC and printing speeds of 60 mm/s. The printing head can travel at a maximum speed of 120 mm/s, with an acceleration of up to 500 mm/s2. There are 3 options available for the extruder: 12 V 50 W, 24 V 50 W, and 24 V 70 W.

Pet Food / Fish Feed Production Line endues pet food with the amount of nutrition, digestible structure, novel shape, and unique taste to meet with the needs of modern market. 1000kg/h High Performance Conical Twin Screw Pet Food Pellet Extruder is extruded into a variety of shapes such as granule or power, and can be floating or sink in water.