HOT PRODUCTS. The company can now produce and sell: pelletizers, feed production lines, and fish feed extruders. Henan Sunshine Industrial Co., Ltd. is a company specializing in the design, research, manufacture, sales and service of animal feed pelletizing machinery. We operate all kinds of fish feed pellet extruders, poultry feed pellet mills

Floating fish feed machine, also called dry type fish feed extruder, is widely used for produce high-grade aquatic feed pellets for fish, catfish, shrimp, Get Price

.jpg)

Dec 1, 2021 · The single s crew fish feed extruder developed was tested based. on the following performance variables. They include c onstant. feed moisture, constant feed rate, and constant screw speed. while

1.Product information Jinan Datong Machinery base on the market demand,to do R&D of fish food production line for various models and settings.By adjusting raw materials,temperature,moisture and other technical parameters, to make our products with characteristics of unique shape, elegant texture, plenty of nutrients, suitable for the usage of different kinds of fish.

1. Feed pellets are germ-free, well-cooked, and easy to digest for the fish. 2. The protein of the materials is denaturalized after being processed by the floating fish feed extruder. It raises the digestibility and tastiness of the feed. 3. The pellets are light, so they can float on the water’s surface.

.jpg)

Reducing feed waste: Floating fish feed has good water stability, floating in water long for several hours, hence avoiding the dissolution of nutrients in the feed and the sinking of feed into the mud, reducing feed waste to a large extent. According to tests, using floating fish feed can save about 10% of feed than using powered or hard pellet

Oct 1, 2001 · The internal fat level was adjusted by continuously injecting fish oil into the preconditioning phase of extrusion system at 0, 0.9, 1.8, 3.6, 7.2 and 14.4 percent levels. As the internal fat addition increased from 0 to 14.4 percent, bulk density of the extruded product increased and external fat absorption decreased (Fig. 1).

.jpg)

Processing and Application of Floating and Sinking Fish Feed. With the further development of the fish farming industry, extruded fish feeds have obtained more and more wide applications in virtue of unique advantages including high nutrients, good palatability, strong digestibility, and so on. As a new technology to produce feed, extrusion

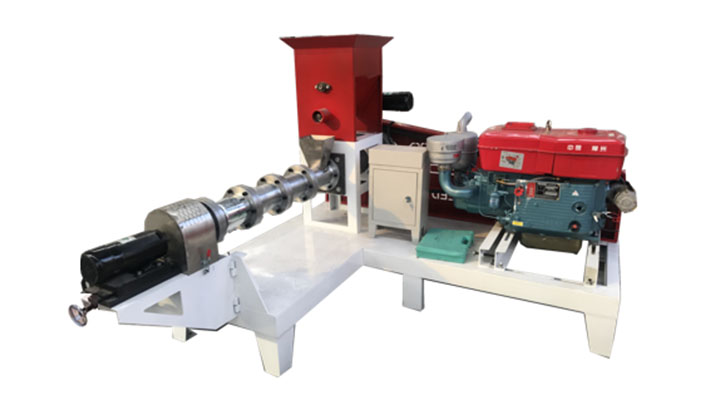

KSh 400,000. Fish Food Pellet Machine Floating Fish Feed. 40 type dry feed extruder Output: 40-50kg/h Host power: 5.5kw Cutter power: 0.4kw Feeding power: KSh 480,000. 300kg Extruder Machine ~Fish Feeds. Heavy machine for commercial users and its easy to operate. KSh 400,000. Grass Fish Feed Machines.

Hot Sell Cat Fish Feed Extruder Machine , Find Complete Details about Hot Sell Cat Fish Feed Extruder Machine,Floating Fish Feed Making Machine,Fish Feed Processing Machine,Animal Feed Extruder Machine from Feed Processing Machines Supplier or Manufacturer-Henan Sunshine Industry Co., Ltd.

.jpg)

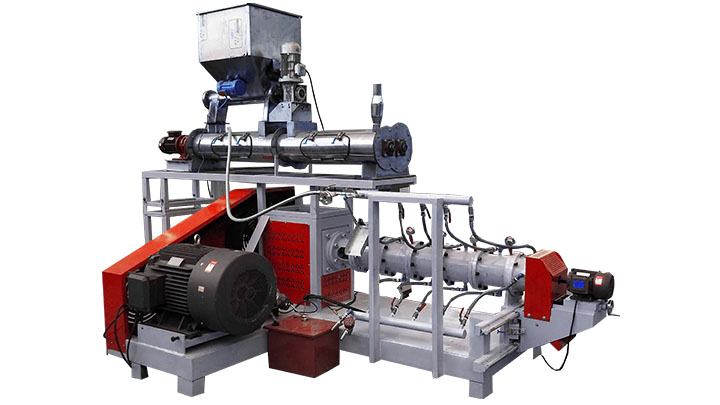

The RCPH120*2 extruder machine for fish feed is mainly used for the 1.5-2t/h production and processing of various floating aquatic feeds. The new type conditioner can soften material fibers, improve gelatinization degree, reduce power consumption and increase production capacity. Main power: 75kw.

.jpg)

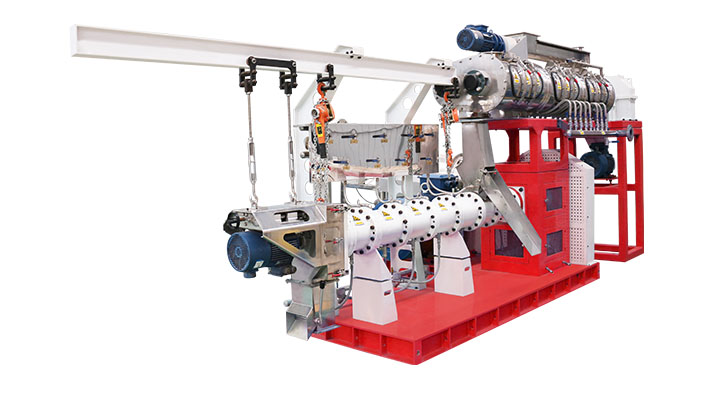

ANDRITZ offers unique, high-capacity extrusion lines for the production of all kinds of feed for fish and shell fish. The ANDRITZ extruders ensure that the feed has the right physical properties – giving it the correct sinking attributes according to where in the water the feed should be accessed. ANDRITZ single screw extruders represent

.jpg)

Consider After-sales Services when you buy fish feed extruder machine in Nigeria. Sometimes, a slightly higher on how to buy fish feed extruder machine in Nigeria can include extended warranties, maintenance services, or training sessions. These add-ons can save significant costs in the long run. 5. Spare Parts Availability.

.jpg)

The fish feed extrusion process consists of several steps: Ingredient Selection: The first step involves sourcing the best quality raw materials like fishmeal, grains, and oils. Grinding: The ingredients are then finely ground to ensure uniformity. Mixing: Ground ingredients are mixed together in a feed mixer machine.

.jpg)

Apr 1, 2004 · Fig. 1: Zones of a single-screw extruder. Fig. 2: Protein molten phase and swollen starch granules. Fig. 1 is a schematic view of a single-screw extruder with different zones. The first section is the feed zone, where the formula mix is added to the extruder. This zone is characterized by deep channel screws designed to convey.