Jun 5, 2023 · The Process 11 Twin-Screw Extruder can be used for cathode slurry compounding. The lab-scale extruder with an 11 mm screw diameter is small enough to be placed onto a safety work bench. A gravimetric powder feeder is used to control the cathode material throughput.

.jpg)

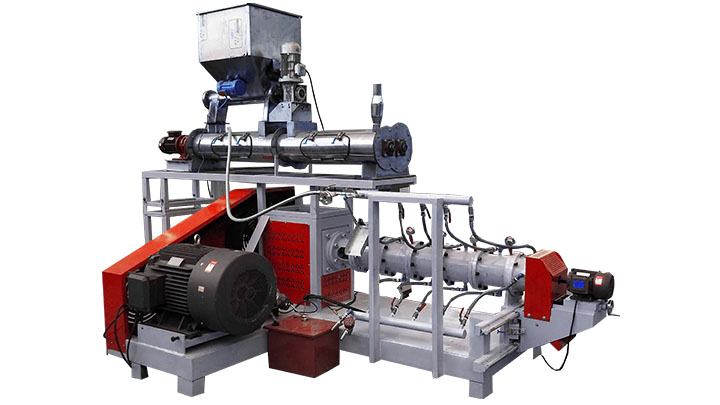

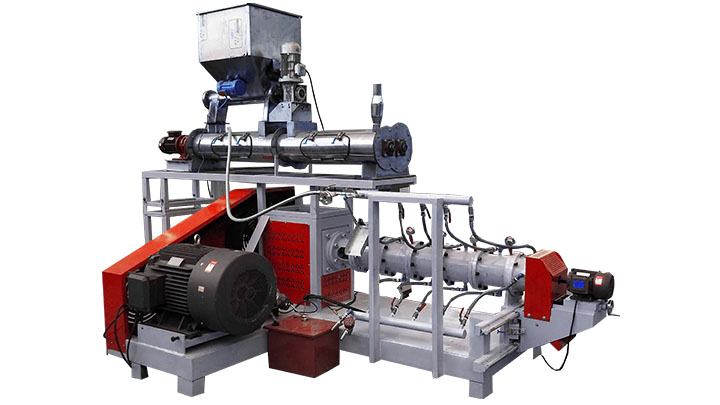

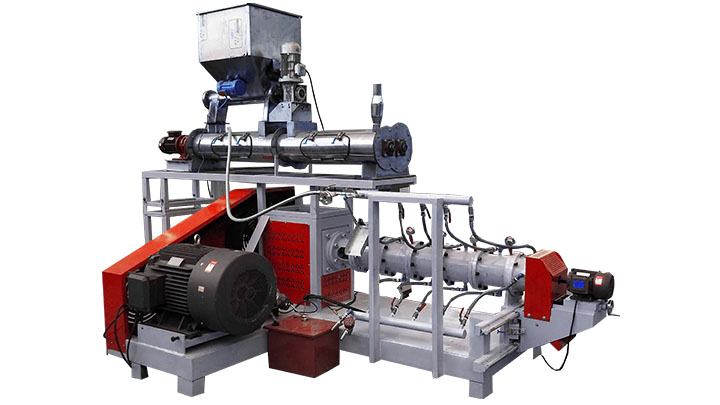

A conical Twin screw extruder is a type of form of barrel and screw of the extruder. In conical extruders, the extruder is designated by the screw diameter at the end of the metering section. While, in parallel extruder size is the diameter of the flight. Conical twin screw extruders are shorter and have a higher replacement cost of the barrel

.jpg)

The conical twin-screw extruder can be applied to various formulations of PVC environmental protection water supply pipes, UPVC drainage pipes, CPVC hot water pipes, UPVC square rain downpipes, PVC double-wall corrugated pipes, PVC power cable sheathing pipes, and PVC industrial trunkings, And other moldings, as well as the configuration and

Conical Twin Screw Extruder CTSE. Gentle and effective kneading properties for shear-sensitive materials such as PVC. Nitrided barrel surface for long service life even with abrasive products. Polished and chrome-plated screws, also available in various special steels. With degassing. Conical Twin Screw Extruder CTSE Contact.

Dimensions [mm] – 220120 –. 30. ompact and robustConical twin-screw extruders for profile extrusionConical twin-screw extruders from KraussMaffei Berstorff are particularly suitable for the middle and l. wer output range and feature a large number of impressive advantages. The. logy flexibility and process stability.Your advantages at.

Conical Twin Screw Extruder The twin-screw extruder has two identical screws as one of its major components. These screws can be conical or parallel. The conical screw extruder is used for processing U PVC. The structure is so built that the output is improved by 30% from the traditional models.

.jpg)

The HAAKE MiniCTW Micro-Conical Twin Screw Compounder is ideal for the precisely controlled reactive extrusion of high-viscous melts that is being done via an MS-Windows™based software that offers several test set-ups. By running the instrument in circulation mode, the required reaction time for the reactive mixture can be controlled easily.

.jpg)

Twin screw extruders are available in these basic designs: High-speed, energy input TSEs that melt the polymer early and are designed as mass-transfer devices: Co-rotating intermeshing. Counter-rotating intermeshing. Counter-rotating non-intermeshing (or tangential) Co-rotating intermeshing screw set. Low-speed late fusion TSEs that are

The counter-rotating conical twin screw extruder is ideal for quality control, product development and research purposes. Your advantages • Gentle and effective kneading properties for shear-sensitive materials such as PVC • Nitrided barrel surface for long service life even with abrasive products • Polished and chrome-plated screws, also available in various special steels • With

PVC extruder EXT-SJZ series. for thermosetting polymer conical twin-screw compact. Output: 150, 400, 250, 750 kg/h. Screw diameter: 92, 55, 80, 65 mm. Power: 55, 37, 110, 22 kW. Conical twin screw structure, screw d55-92mm Double screw forced feeding with synchronized control Large lcd control panel Self-developed

.jpg)

Parallel Counter-rotating Twin Screw Extruder is the better solution for working PVC+100 p.h.r CaCO3. Parallel Screw are longer than the conical one, in fact with a L/D ratio of 1/30 the former are well suggested in order to guarantee a good jellification of the material. The shape of parallel screw gives more time to the plasticization process

.jpg)

Conical Twin-screw Extruder. All kinds of SJZ extruders that our company designs especially for producing the PVC pipe ,profile sheet and plate, our extruders can promise a good plasticization, high capacity and advanced electric control, and the electrical cabinet can be chosen by customer according to their own demands.

Xplore's high quality, co and counter-rotating twin-screw micro compounders are fully-fledged material processing instruments that fit on a laboratory bench or in a fume cupboard. The core of the compounders is a vertically positioned, liquid-tight barrel with two easily detachable, conical mixing screws. Both screws and housing are specially

.jpg)

May 28, 2020 · The parallel twin-screw extruder and the conical twin-screw extruder have the same features: they have the conveying mechanism to push the plastic forward forcibly, good mixing plasticizing ability and dehydration ability, and basically have the same adaptability to the molding process of materials and plastic products.

.jpg)

If you are looking to sell your used twin screw corotate extruder submit a request online or contact Erik Eichert at 630-238-7480. 10 Extruders - Twin Screw CoRotate SEARCH FILTER SORT GRID List Photos Used-Leistritz LSM 30.34 Twin Screw Co-Rotating Twin Screw Extruder Stock# 52915001