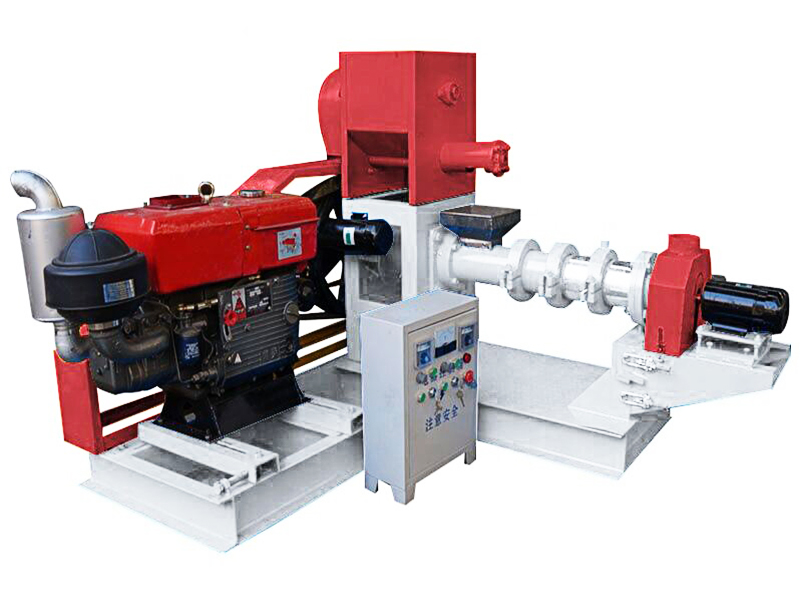

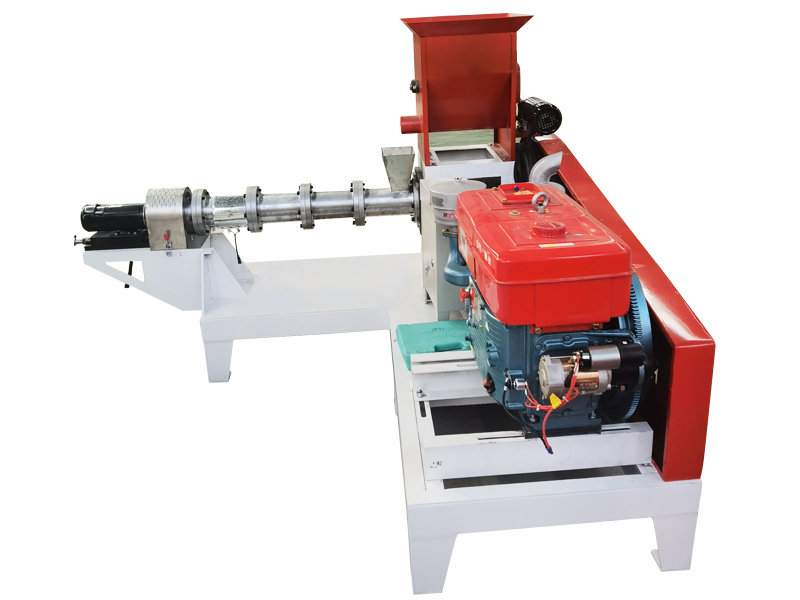

Processing Range of Raw Ingredients: soybean, wheat bran, corn, meal, corn straw, peanut shell, rice husk, straw, as well as some other raw materials associated with the feeding formula. Main Machinery: feeding machine, crusher, mixer and storage silo, pellet mill and automatic electric cabinet.

Ring Die Feed Pellet Mill - Large Scale This animal feed pellet mill is mainly consist of feeding device (screw feeder), hardening and tempering device (conditioner), face plate, press chamber transmission system, overload protection and electrical control system.

Flat Die Feed Mill. Ring Die Feed Mill. Large-scale production of feed pellet is done using ring die pellet machines while small-scale production utilizes flat die pellet machines. The ring die type machine is used to grind and mix, unlike the flat die mills which simply processes the dry powder into pellets.

Vietnam sheep feed machine-Feed pellet Machine for Sale Vietnam aims for commercial sheep meat production – Asian 2021/03/05 · The grazing model is no longer suitable to sheep farmers in Ninh Thuan province when natural grasslands are Feed crushing machine Feed Mixing Machine Fish Feed Machine Fish Feed Production Line

Mar 30, 2021 · In sheep, whole grains are large enough to be ruminated and chewed and do not require processing, except in young lambs (creep feed). Processing grains creates smaller particles that are more palatable to lambs, thus increasing intake. General processing guidelines are: For lambs less than 9 kg (20 lb.) liveweight, process all grains.

alfalfa feed pellet mill is the main machine for pressing feed. It is suitable for large and medium-sized farms and small and medium-sized feed factories. It can produce 3-12 tons of pellets at a time, and can be used with 20,000 tons of powder feed plants. For making alfalfa.

large scale feed production line sheep Vietnam-Feed Pelleting Machine PIG PRODUCTION AND MARKETING IN VIETNAM - tlri.gov.twPig production in Vietnam is mainly comprised of three systems, they are: (i) small-scale householders with low level of hygie Tel:8619337889051 Email:sale@limamachinery.com Home Products Feed crushing machine

Mar 2, 2020 · Feeding Equipment. Many types of feeding equipment are available to feed sheep. Pails and buckets are often used for a small number of sheep. For large quantities, some type of automation can greatly reduce the required manual labor. Feed mixing wagons and food delivery wagons make the fence line feed bunk an attractive option.

In Vietnam, rice husk was largely considered as a waste product that was often burned or dumped on landfills, which results in environmental problems. When searching for a way to use these husks as an energy source in place of fuel oil, rice husk pellets are turn out to be the right way.

The feed pelletizing machine is the ring die design which is broadly used to large capacity feed pellets production. If you have another questions about feed pellets production requirements like capacity or scale, please send e-mail to us for more support and guidance.

We offer a full range of tested and proven feed processing systems that make the manufacturing of animal feed both labour-saving and cost-effective. Our Feed Pelletizers are reliable, high-yielding and affordable. Sort by Default Display 15 Products per page Flat Die Pellet Mill

Feed pellet mill for sheep is a simple 6 step process: Step 1 is the grinding process by which the feed crushing machinery creates a powder from all sheep feed raw materials . Step 2 is the when the feed mixer then mixes the powder with sheep feed, thereby creating the feeding mixture. Step 3 is the feed pelleting process, through which the

Processing of oilseeds locally is now on the rise, therefore there is potential in supplying oil pressing and processing equipment. Common oil seeds produced in the country include sunflower, sesame, groundnuts, palm oils, etc. Textile and apparel: Tanzania produces abundant cotton but only 20 percent is locally processed.

Grinder, mixer, pelleting machine, freezer, sifter, weight scale, packaging bags and more are some of the necessary feed processing equipment for starting a complete cattle feed production factory. Here you can see a 3-5 ton/h cattle feed manufacturing process flow chart.

Chopping avoids the selective feeding thus wastage of plant material is reduced. The machine used for the intended purpose is called chaff cutter. Chopping facilitates easy handling due to increased bulk density also improves digestion due to exposure of relatively large surface area of roughages for microbial digesting •