Hot supply stable running quality modern style low cost 0.5mm . 3.The floating fish feed twin screw extruder machine mainly produces cat food,sinking or floatingfish feed,dog food,modified starch,puff snacks,etc. 2.Main features of fish feed extruder are as follows: 1.

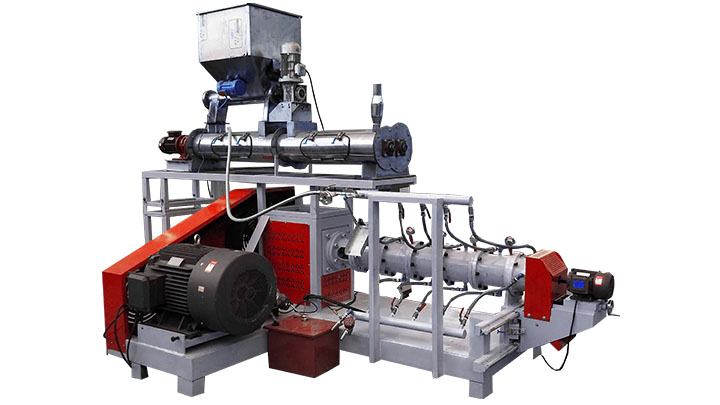

The RCPH120*2 extruder machine for fish feed is mainly used for the 1.5-2t/h production and processing of various floating aquatic feeds. The new type conditioner can soften material fibers, improve gelatinization degree, reduce power consumption and increase production capacity. Main power: 75kw.

.jpg)

See full list on aquafeedmachine.com RICHI floating fish feed extruder machine adopts frequency conversion main motor, the transmission system is strong, stable and reliable. The heating and cooling layer of the barrel is an integral forging structure, the inner sleeve of the barrel and the screw element are made of high wear-resistant alloy steel, and the template uses new materials See full list on aquafeedmachine.com 3-4T/H floating fish feed extruder price 90,000-110,000USD. Nowadays, most of the world’s aquatic feed production adopts extrusion processing technology, and more and more feed processing enterprises are gradually replacing traditional pellet mills with extrusion fish feed extruders to produce aquatic feed and other special feeds. In the aquatic fe... See full list on aquafeedmachine.com Richi Machinery is a relatively professional feed extruder manufacturer in China. All fish feed extruders are designed, produced, assembled and tested in accordance with ISO international quality certification system standards. The sales network covers more than 130 countries and regions around the world, such as Russia, Indonesia, Iran, Kazakhstan... See full list on aquafeedmachine.com Maturity degree of starch During the working process of the floating fish feed extruder machine, the ripening degree of starch is very important, which directly affects the feed digestibility of aquatic organisms and improves the stability of feed products in water. The ripening degree of starch is affected by the type of starch, crushing particle size and processing conditions during processing. The operation of the conditioning device or fish pellet extruder also has a great influence on the maturity of starch. 1. T... Floating and sinking materials The floatability of extruded aquatic feed is directly related to the bulk density of the processed final product. Usually, the bulk density of freshwater floating feed is less than 440g/L, and that of seawater (20℃ seawater, 3% salinity) is less than 480g/L. At the exit of the extruder and the outlet of the dryer are the bulk density of the wet material and the bulk density of the dry material respectively. It is impractical to measure the bulk density of the feed product after it is dry, so... Grease addition Oil and fat raw materials are the best energy sources for aquatic animals, and 2% to 40% of oil can be added to the formula according to the needs of aquatic organisms. The source of oil can be obtained from dry materials, vegetable oil or animal oil, such as full-fat soybeans, soybean oil or fish oil. In the actual operation of the twin-screw floating fish feed extruder machine processing technology, it is recommended that the fat content in the formula (the total fat content in the extruder... See full list on aquafeedmachine.com In line with the benign development needs of global fish farming feed towards low pollution, low waste, high efficiency, and high conversion, aquatic extruded feed is gradually being accepted and recognized by the market, and has become a new trend in the development of the industry. With the promotion and application of extruded feed in the breedi... See full list on aquafeedmachine.com A complete set of extruded feed processing system includes a series of feed equipment such as floating fish feed extruder machine, ultrafine pulverizer, dryer, mixer, sprayer, cooler, screening machine, and packaging machine. See full list on aquafeedmachine.com Richi Machinery is a provider of aqua feed machinery equipment and whole fish feed mill plant engineering system solutions with the feed industry as the main body. With nearly 30 years of word-of-mouth accumulation, the RICHI brand integrates R&D, production, sales and service, and is trustworthy! The equipment models are complete, and the product ... See full list on aquafeedmachine.com All the services we provide are to ensure the operation of the client’s project. Since Richi Machinery was established, we have always adhered to the service concept of “full life cycle, full value chain” to provide you with worry-free services throughout the life cycle from pre-sales, sales to after-sales, and integrate value-added services into e... See full list on aquafeedmachine.com

.jpg)

Sinking Fish Feed Extruder Machinery Plant , Fish Feed Production Machine SLG135 Fish Feed Extruder , Twin Screw Fish Food Making Machine ABB Inverter Animal Floating Fish Feed Extruder Processing Machine 150-5000 kg/h Capacity

.jpg)

Twin Screw Conveyor Fish Pellet Extruder Floating Fish Feed Extruder Machine Description Fish feed processing / pet food line, use meat power, fish meal, bone meal, corn floir, cereals, and beans are used as raw materials. to produce floating / sinking fish feed with tinique taste and new shape, such as heat, bones, stars, traingle, circles

Apr 10, 2024 · Function: Fully automatic production of floating fish feed Output: 2 tons per hour Shipping method: Shipping Main equipment: mixer, feed extruder, cooler, dryer, seasoning machine, packaging machine. Order Date: 2024/2/12 This customer runs a fish feed factory, and later wants to expand the business into pet feed.

Dec 1, 2021 · The single s crew fish feed extruder developed was tested based. on the following performance variables. They include c onstant. feed moisture, constant feed rate, and constant screw speed. while

.jpg)

High quality Twin Screw SUS Fish Feed Extruder Fish Food Manufacturing Machines from China, China's leading Twin SUS Fish Feed Extruder product, with strict quality control Twin SUS Fish Food Manufacturing Machines factories, producing high quality 100KG/H SUS Fish Feed Extruder products.

.jpg)

High quality Twin Screw Extruder Floating Fish Feed Pellet Machine Production Line from China, China's leading Twin Screw Floating Fish Feed Pellet Machine product, with strict quality control 160kg/h Floating Fish Feed Pellet Machine factories, producing high quality 160kg/h fish feed extruder machine products.

Jan 1, 2017 · While single-screw extrusion (SSE) is a mechanically simple and low-cost processing option, twin-screw extrusion (TSE) has been used extensively for mixing, compounding, or agglomerating a variety of ingredients to produce a wider range of products. Download : Download full-size image. Figure 31.1. Types of extruders.

Sep 22, 2023 · SBX Master™ Twin Screw Extruder. Baker Perkins’ versatile SBX Master™ twin-screw extruders provide continuous production at outputs from 250 to 2,500kg/hour, depending on formulation. The extruders can be configured for a wide range of applications, including high and low moisture Texturised Vegetable Proteins (TVP), ingredients, and a

.jpg)

the extruder feed opening, incorporation of a vent into the feed hopper, use of higher pitch elements (2 times extruder diameter), use of increased free volume undercut profile “pushing” SK type elements in the feed opening, and extending the length of the conveying zone in the extruder feed section. Kapfer et al. [3] reviewed the

.jpg)

The fish feed produced by twin-screw extruder can be easily absorbed by fish and livestock, and can reduce fish disease without polluting the water. Main Components of Twin-Screw Fish Feed Extruder. The main body is made of stainless steel with high safety performance and long service life. The feeding system, driving system and cutting system

Save money on feed processing machines when you shop for fish feed twin screw extruder machine atLima.com. Discover permanently low prices when you buy direct from Chinese wholesalers.

.jpg)

The Thermo Scientific Process 16 Twin-Screw Extruder is a highly modular extrusion system with a wide range of options and accessories designed to meet your processing requirements. Fast and reliable material development for the polymer, food, and pharmaceutical industries. Use as little as 0.4 kg of material or go up to 18 kg/h to optimize