.jpg)

Ability to handle even the most difficult pet food and feed materials through use of highly accurate Coperion K-Tron feeders. Extremely versatile Coperion ZSK Mv PLUS twin screw extruders and specially designed pelletizers/dies can achieve even the most complex pet product profile. High free screw volume of Coperion ZSK extruder design can

Jul 1, 2017 · IFT is a forum for passionate food professionals and students to collaborate, learn, and contribute all with the goal of inspiring and transforming collective knowledge into innovative solutions for the benefit of all people around the world. Our Community Join Us. 11,000+. 90+.

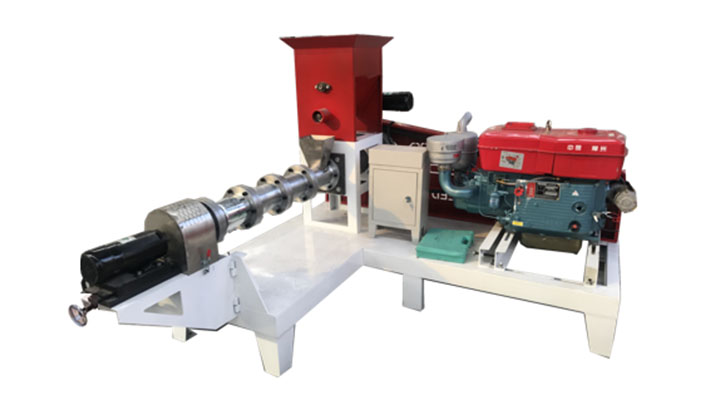

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

.jpg)

New Design Floating Fish Food Making Machine, Find Details and Price about Fish Feed Equipment Fish Food Extruder from New Design Floating Fish Food Making Machine - Jinan Datong Machinery Co., Ltd. Print This Page

.jpg)

Nov 4, 2021 · 7139. Wenger revolutionises twin screw extrusion with unique models dedicated to petfood and aqua feeds. Traditional twin-screw extrusion design has served its purpose as the petfood and aqua feed industries developed. Yet both industries now stand at a tipping point where new trends are pushing the traditional systems beyond their limit.

The production line has reasonable equipment design, high degree of automation, precise control of extrusion process parameters and innovative design of temperator, which further improves the curing effect of feed.

The new extruder features AMANDUS KAHL stop bolt technology for ideal mixing and venting in the first cylinder section. Special process sections for compaction, cooking and kneading provide a high degree of flexibility and a wide range of setting options for processing feed. Exchangeable screw elements ensure perfect adaptation to different

To meet new formulation challenges, a revolutionary extrusion system designed to fit the local markets was required. With a 40-year history in feed production, lDAH developed its answer: ContraTwin. lt is designed with twin-screw extrusion features but with re-engineered screw designs and rotation direction to accommodate future feed formulation. Developed to convey very sticky and puffy

Many developments are available as upgrades for existing machinery – often, original machine performance can be exceeded, and service life given a worthwhile extension. UK bpltd@bakerperkins.com. US bpinc@bakerperkins.com. UK +44 1733 283000. US +1 616 784 3111. 19 to 21. Baker Perkins are a leading global food extruder manufacturers and have

.jpg)

Clextral extrusion systems efficiently produce high-energy feed with a precise balance of proteins, oils and carbohydrates, processed for optimum digestibility. Extruded feeds are produced to match fish feeding habits (floating, neutral buoyancy or sinking) to energize feeding and reduce waste.

to design and develop a laboratory single screw extruder for compounding polymer and polymer composites. The specific objectives include: a. To design a single screw extruder machine frame. b. To evaluate the efficiency of the single screw extruder machine. c. To construct the extruder using local resources. d.

.jpg)

Components of Fish Food Extruder A fish food extruder is a sophisticated piece of machinery designed to efficiently produce high-quality fish food pellets. Understanding its components is crucial for optimizing its performance. First and foremost, the extrusion barrel serves as the core component of the fish food extruder.

.jpg)

Shop for a new design floating fish feed extruder machine from a Chinese wholesaler atLima.com and find a wide selection of pet food processing machines that meets your needs.

.jpg)

Floating Fish Feed Extruder Machine 3-4T/H. Floating Fish Feed Pellet Making Machine 4-5T/H. Floating Fish Feed Pellet Mill 6-7T/H. Fish Feed Pellet Extruder 8-10T/H. Floating Fish Pellet Machine For Sale 10-12T/H. Sinking Fish Feed Machine. Menu Toggle. Fish Feed Processing Line. Sinking Fish Feed Pellet Mill 0.6-1.2T/H.

.jpg)

Extruders have been somewhat limited in terms of capacity when producing small-diameter floating or sinking aquatic feeds. Extruders require restriction or die hole number limitation for developing the back pressure and energy required for product expansion and the cooking effect for floating feeds. Extruders also require more holes or a greater op See full list on globalseafood.org A general plant review is needed before changes can be implemented to achieve higher extruder capacity. Does your mixing and grinding system achieve a good mix on finely ground raw materials? Is your grinding equipment designed to achieve a fine grind for small die openings at a significantly higher capacity? It is recommended that all particles be... See full list on globalseafood.org The authors studied extrusion and streamlined the process in order to achieve higher rates for small-diameter feeds. This was accomplished and patented for both single- and twin-screw extruder designs. The traditional cone screw was removed, and a divergent cone screw was placed on the single-screw extruder. The twin-screw model required some addit... See full list on globalseafood.org Similar capacity problems existed when making small-diameter sinking feeds such as shrimp feeds. Knowing that aquatic feed producers generally make a range of products, a die to increase sinking feed capacity as well as density needed to be developed for use alone or in conjunction with the diverging-cone screw discussed above. An oblique tube die ... See full list on globalseafood.org The question always remains after changing a feed production process whether the change adversely affects the growth rate of the animals to be fed. Feed was therefore produced and shipped to Texas A&M University in Port Aransas, Texas, USA, where the second author fed shrimp to verify their growth. The feed was a proven formula with reduced fishmea... See full list on globalseafood.org Interest in the extrusion of shrimp feeds has mostly centered on the ability to modify the formula and achieve growth at a lower cost. This has been possible for years, for extruders can handle higher levels of vegetable proteins and lower levels of fishmeal, resulting in feed with good characteristics as well as lower cost and good shrimp growth r... See full list on globalseafood.org