.jpg)

Residual feed particles can accumulate in various parts of the floating fish feed pellet machine in Australia, affecting its performance. Daily cleaning after operations can prevent this buildup. Lubrication. Proper lubrication is essential for the floating fish feed pellet machine smooth operation. Neglecting this can result in increased wear

.jpg)

Floating Fish Feed Pellet Machine . Keyul Enterprise is well-known as one of the reliable Floating Fish Feed Pellet Machine Manufacturers in India. The unmatched quality and excellent performance have attracted potential buyers from all across the globe to place repeated orders.

A pellet machine is a machine that transforms raw materials into tiny, dense pellets. These pellets are typically used as fuel for heating, cooking, or industrial processes. A pellet mill can process a wide variety of materials, includingfish, agricultural waste, and other organic materials, into pellets of uniform size and shape.

2)The feed pellet diameter can be 0.9-8mm,length adjustable. 3) The pellet smooth, nutrition. Our floating fish feed extruder machine is based on the Raw material of corn meal, flour, Wheat middling, Wheat bran, rice bran, soybean meal, cottonseed meal, fish meal, bone meal, meat meal and etc.

.jpg)

A: In India’s ever-growing aquaculture sector, employing an automatic fish feed machine offers several advantages: 1. Efficiency: Automatic fish feed making machine in India significantly speed up the feed production process compared to manual methods, allowing for more production in less time. 2.

Oct 16, 2018 · The final pellets have unique shape and good taste, high nutrition and smooth textures. For feeds of fish and shrimp, the floating time in water can be adjusted by the extrusion degree adjustment. Feed pellets dia. is 0.9-15mm. We have wet type fish feed extruder and dry type fish feed extruder for your choice.

The main nutrient component is the starch with a content of 10% to 15% for sinking fish feeds and over 20% for floating fish feeds. Generally, starch content can be between 5% to 60%. Carbohydrates in extruding fish feed pellets act as an emulsifier, suspending agent and adhesive. HOT Sale Fish Feed Making Unit in Our Factory (150kg/h)

.jpg)

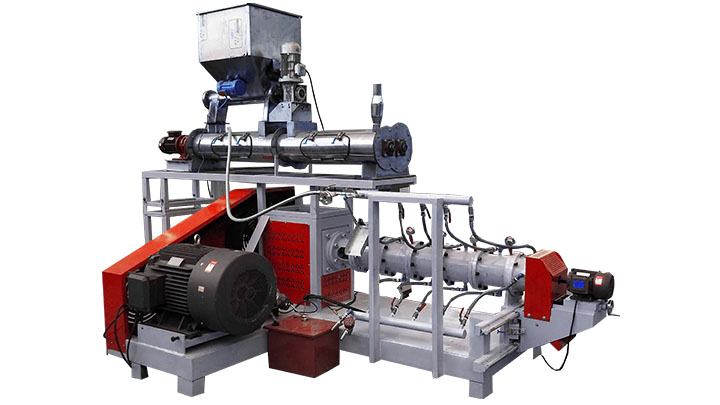

As the professional Floating Fish Feed Pellet Machine ,our Floating Fish Feed Pellet Machine extruder machine design good manufacturing process. Brand Name:Loyal. Model Number:PFE-65-1 PFE-70-1 PFE-85-1 PFE-90-1 Place of Origin:Shandong China. Certification:CE,ISO9001,SGS,BV.

.jpg)

Stainless Steel Dog Floating Fish Chicken Animal Feed Pellet Making Machine Price Floating Fish Pet Food Feed Machinery $ 900 .00 - $ 1,180 .00 Min Order: 1 set

.jpg)

Poultry Feed Pellet Machine Price Range. For small-scale operations, basic poultry feed pellet machines can start as low as $500 to $1000. Mid-range options, suitable for moderate production levels, may range from $2000 to $5000. For larger farms or commercial feed production, machines can exceed $10,000, reflecting their higher capacity and

Save money on feed processing machines when you shop for floating fish feed pellet machine new design atLima.com. Discover permanently low prices when you buy direct from Chinese wholesalers.

.jpg)

Size. 1260*860*1250mm. Weight. 290kg. Get Quote. Our fish feed extruder, also called floating fish feed pellet machine, can produce fish food pellets by heating and expanding with a certain proportion of various kinds of cornmeal, fishmeal, flour and other mixes. This fish feed pellet making machine can not only produce feed for aquatics like

We are a professional manufacturer focusing on manufacturing of fish feed pellet machine. Our floating fish feed pellet mill production capacity covers 40kg to 1000kg per hour. In addition to stand-alone machines, we are also good at designing and integrating complete fish food production lines with flexible configurations.

.jpg)

Key Features to Look For. When choosing the right fish feed pellet machine, consider the machine’s efficiency, reliability, and durability. An efficient machine will consume less energy and produce more pellets per hour, which can significantly reduce your costs in the long run. Next, a reliable machine will have fewer breakdowns and require

.jpg)

5. Fish Feed: Feed is a recurring cost. Initially, for a small-scale farm, one might budget between ₦200,000 to ₦500,000. 6. Labor and Training: Hiring workers or undergoing training sessions may add ₦50,000 to ₦200,000, depending on the scale. 7. Miscellaneous Costs: