.jpg)

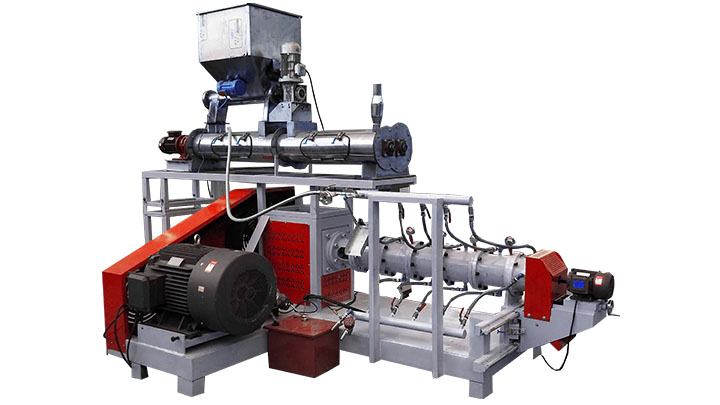

The multifunctional single-screw extruder offers a modular design to meet a wide range of process requirements for your pet food and aqua feed production. Capacity, screw speed, torque and pressure options provide excellent versatility.

.jpg)

Oct 17, 2020 · Greater overall process flexibility. In aqua feed production, the best possible uniformity and high level of degassing decreases the chances of floating pellets when sinking aqua feed is produced. Thanks to the action of the two screws, twin-screw extrusion allows us to produce micro-pellets of up to 500 microns (0.5 mm).

Nov 11, 2014 · Single-screw extruders are used to produce virtually all of the extruded soybeans in livestock feeding. Twin-screw technology involves much higher capital costs — about 1.5 to 2.5 times higher than a state-of-the-art single-screw extruder of comparable hourly production capacity. This is due to the complexity of the screws, shearlocks

Aug 25, 2020 · This article was published in the June 2020 issue of Pet Food Processing.Read it and other articles from this issue in our June digital edition.. There are numerous cold extrusion applications in the pet food industry that can be broken down into different segments such as products (animal feed, treats, supplements and medicines), formats (fresh, shelf stable, wet, semi-moist, dry, freeze

TX-series extruders Preconditioner Crammer feeder. Extrusion Systems. TX-series extruders. Fully intermeshing, co-rotating twin-screw extruder. Nominal barrel bore diameters from 32 mm to 120 mm. Production capacities varying from 50 kg/h up to 4500 kg/h. Fully automated PLC control system.

.jpg)

Complete Extruded Dry Pet Food, Wet Pet Food, Fish Food or Pet Treat Systems Capability. Whether manufacturing in a batch process or in higher volumes via continuous methods, Coperion and Coperion K-Tron feeders and material handling equipment as well as Coperion high efficiency extruders are used throughout the dry pet food, wet pet food and pet treat as well as aquatic fish feed

.jpg)

With Wenger, you make nutricious and delicious products that pets (of all sizes) love to eat. And eat. And eat. Through careful testing and extensive research, our world-class team helps you develop premium foods and treats, and the processes to produce them at scale. Pet food producers globally trust Wenger for extrusion cooking and drying

Our cold (dry) feed extruder has many advantages as follow: 1. easy opertion and convenient maintainance. 2. long life to run. 3. high temperature in the extruding chamber (max. 160centigrade) according to yoru demand to killing urea enzyme of soybean ,long time storage for rice bran , or Cotton Seed De-Toxin.

Floating Fish Feed Extruder Machine 3-4T/H. Floating Fish Feed Pellet Making Machine 4-5T/H. Floating Fish Feed Pellet Mill 6-7T/H. Fish Feed Pellet Extruder 8-10T/H. Floating Fish Pellet Machine For Sale 10-12T/H. Sinking Fish Feed Machine. Menu Toggle. Fish Feed Processing Line. Sinking Fish Feed Pellet Mill 0.6-1.2T/H.

.jpg)

Adopting alloy steel as material, Our dry-type fish feed extruder has been widely used in small-scale and medium-scale fish farms or feed plants to produce aqua feed and also dog/cat pet feed in virtue of its simple structure and low noise. Other than the dry type, the wet type fish feed extruder machine is equipped with a boiler that can add

.jpg)

SunPring Food & Feed Extruder design, manufacture and install complete food production line for different types of food and feed. [email protected] +86 186-6376-4200 changhuibiz No.258 Tianjiazhuang Institute, Huaiyin District, Jinan City, Shandong, China

.jpg)

This twin-screw extruder is the ideal companion to recipes with a large volume of meat slurries or fresh meat. The New ANDRITZ twin screw extruder ensures complete utilization of starch and ensures total material discharge, for the best hygienic conditions as well as quick recipe changes. Watch our product animation to see the NEW ExTS 718 in

8-10 t/h fish feed pellet extruder price. 8-10 t/h fish feed extruder cost: 190000 – 210000 USD. The technical performance of this equipment has approached or basically reached the level of twin-screw feed pellet extruders of internationally renowned brands, but its price is only one-third to one-half of the price of imported products, providing feed and food processing enterprises in

May 20, 2011 · Blend back with the other ingredients and cold extrude. (ii) Separate the cereal grain and hot extrude it under dryer conditions than the normal fish feed pellet, thoroughly breaking down all the starch. Add the cereal kibble back to the other ingredients as a new ingredient then cold extrude.

Producing high-quality extruded aqua feed with good water stability. Floating, slow sinking, and sinking extruded aqua feed for 1.0 to 30 mm extrudates. Special processing for small pellets with a nice appearance. Producing pet food in various forms and shapes. With the precise cutting device, ensuring a smooth pellet surface.