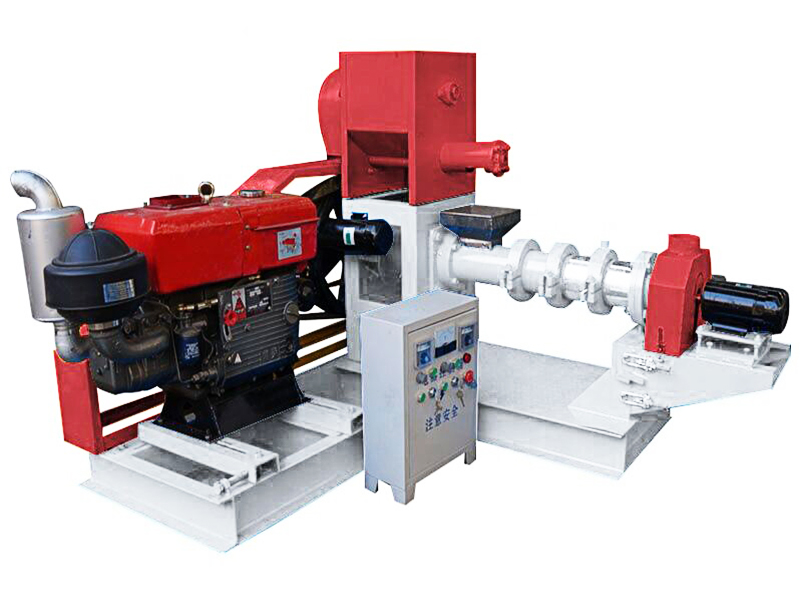

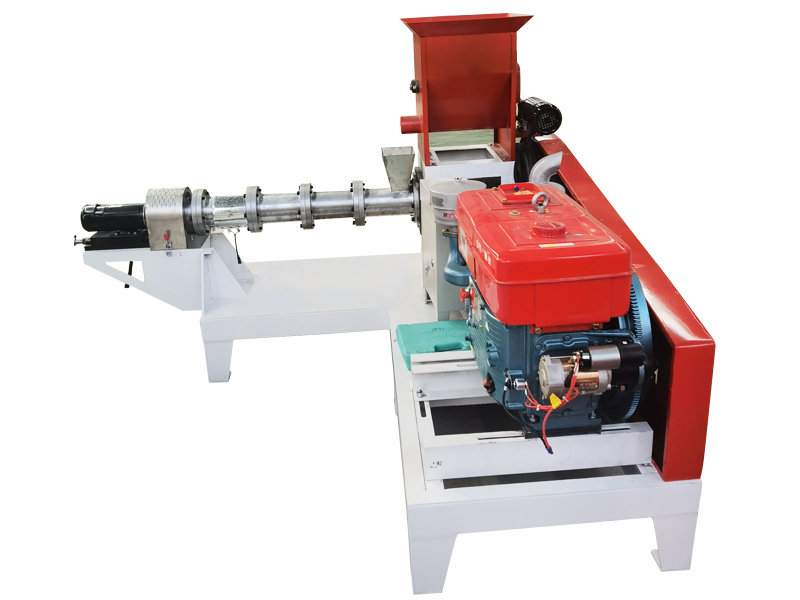

Pellets Pigs Feed Pellet Maker Fish Feed Pellet Machine Best Price Floating Pellets For Tilapia Fish And Pigs Floating Fish Feed Pellet Machine 40 Fish Food Maker Machine. $14,000.00-$15,000.00/ Set. 1 Set (Min. Order) 8 YRS CN. Supplier.

Nov 19, 2019 · Pressing is the core process of pig feed pellets production. During this process, water, temperature and steam pressure have a great influence on the mass of the final pellets. If the moisture content of the raw material is higher than 8-10%, the hardness of the particles will increase. The optimum moisture content is 16-17%.

The reason being that the heat involved during the process of manufacturing pig feed pellets is able to break down carbohydrate bonds. This makes them become more digestible by pigs. Of course for you to make the feed pellets, you will require a good stability pig feed pellet process machine. Pelletizing is a core step for pig feed pellets production.

Oct 09, 2021 · The good thing about this feed pellet production machine ry is that it caters for both small and large farmers. It will help you develop high quality feeds that will improve the growth of your pigs. The machine is great because you will get the feeds without much effort. It will perform most of the tasks for you. You Will Save Money

In the pig breeding process, if it is a small-scale pig farm, the whole set of feeding is usually completed manually. However, if a pig farmer wants to further expand the breeding environment and breeding scale, he needs to purchase breeding equipment and know some knowledge about pig feed formula and purchases pig feed pellet machines.

The animal feed pellet mill is mainly driven by the rotation of the die plate to drive the rotation of the built-in pressing roller to quickly squeeze corn, soybean meal, grass fodder, green fodder, etc. into pellets. Feed pellets processed by the commercial animal feed pellet machine can usually be used to feed cattle, sheep, chickens, pigs

feed pellet mill for sale, Quality Pig Feed Pellet Machine YULONG Brand on sale of Zhangqiu Yulong Machine Co.,Ltd from China.

1. When you are going to make pig feed on your own, the first step is to make sure the moisture of your raw materials is about 10-12%. The wetter or dryer material will affect the final quality of finished pellets. You can use a drier, so that you can get the ideal moisture quickly. Or you can dry it naturally in the sun.

Aug 20, 2019 · Mixing: Mix all the feed materials according to your feed formula. Pelletizing: Feed the formulated feed mixture into feed pellet mill to press them into pellets. Raising pigs in Nigeria is a profitable business endeavor since Nigeria’s economy mainly depends on the agricultural products or agribusiness. Pig farming business can not only meet

Dec 28, 2020 · These machines are of two categories. There is the flat die pellet machine, and the ring die pellet machine. The flat die is increasing at a high rate. They are mostly used by large-scale farmers because of their high-quality end products. Here are the features: 1. To come up with nature pig feed pellets, you need to use the raw materials.

YUDA SZLH678 animal feed pellet making machine - chicken/duck/pig Liyang Yuda Machinery Co., Ltd.

This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the fine powder can mix with the wheat bran, bone

Looking for ideal Pig Feed Pellet Making Machine Manufacturer & supplier ? We have a wide selection at good prices to help you get creative. All the Pig Feed Making Machine are quality guaranteed. We are China Origin Factory of Pig Feed Pellet Machine. If you have any question, please feel free to contact us.

Pig feed pellet machine Screw feeder. The structure is similar to the batcher. The motor is frequency-regulated or speed-regulated, and there is a steam baffle at the feed inlet. The function of this machine is to evenly send the materials from the granulator bin to the conditioner, and the feeding speed can be adjusted according to the load of the main motor of the pig feed pellet machine.

Generally, the length after pulverization by the crushing system of the feed crusher is 6 mm or less. The common animal feed crushing machine is the pig feed hammer mill grinder. (3)Mixing And Stirring Process. After the pulverization process of the pig feed pellet making plant, the material conveyed to the mixing and agitation process.