Conveying raw materials.Feeding the raw materials through the feeder into the Pig feed pellet machine. By doing that, the raw materials will be compressed to die's columned holes and subsequently discharged from the pig feed pellet machine. Cooling and storage: After processing of the pig feed pellets, they are often soft and hot. A cooling machine will help in taking away both the heat and moisture on the pig feed pellets surface.

The pellet machine is a ring die placed flat, which is suitable for all biomass raw materials in terms of working principle; Adopting timing and quantitative feeding device. The lubricating oil device is automatically supplied dynamically and regularly. Fully enclosed, fully automatic, maintenance-free, and can work continuously for 24 hours;

Generally, the length after pulverization by the crushing system of the feed crusher is 6 mm or less. The common animal feed crushing machine is the pig feed hammer mill grinder. (3)Mixing And Stirring Process. After the pulverization process of the pig feed pellet making plant, the material conveyed to the mixing and agitation process.

Pulverous pig feed is consisted of crushed pig feed raw materials. However, pig feed pellets is made of pig feed raw materials, compressed by an animal feed pellet mill. Under the action of 65-70 degrees hot temperature during the pelletizing process, pig feed pellets will soon become gelatinized and generate a better taste. It is easier for

For pig feed pellets making, the screen sieve diameter of feed hammer mill is less than 1mm, while for weaned piglet is only 0.3mm. Raw materials mixing. Mixing is an essential operation for the whole pig feed pellets production line. Grounded raw materials should mix evenly before sent to be pressed.

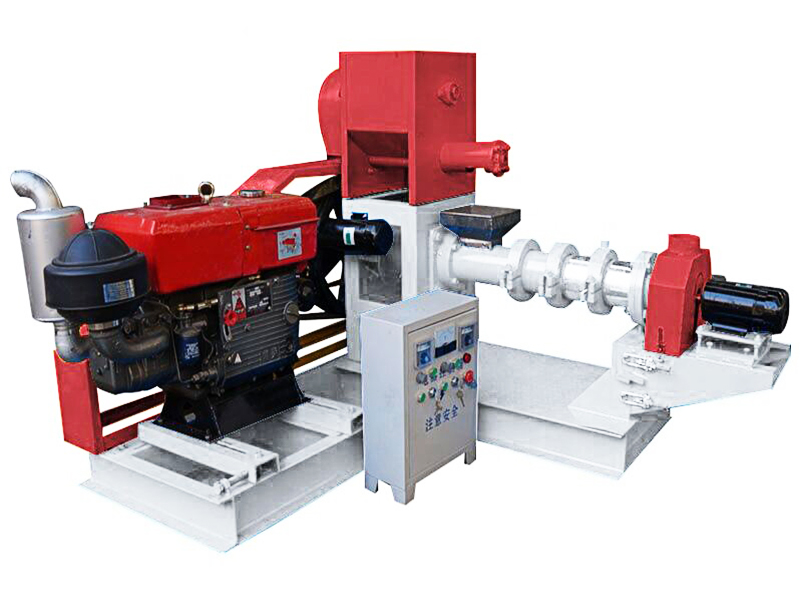

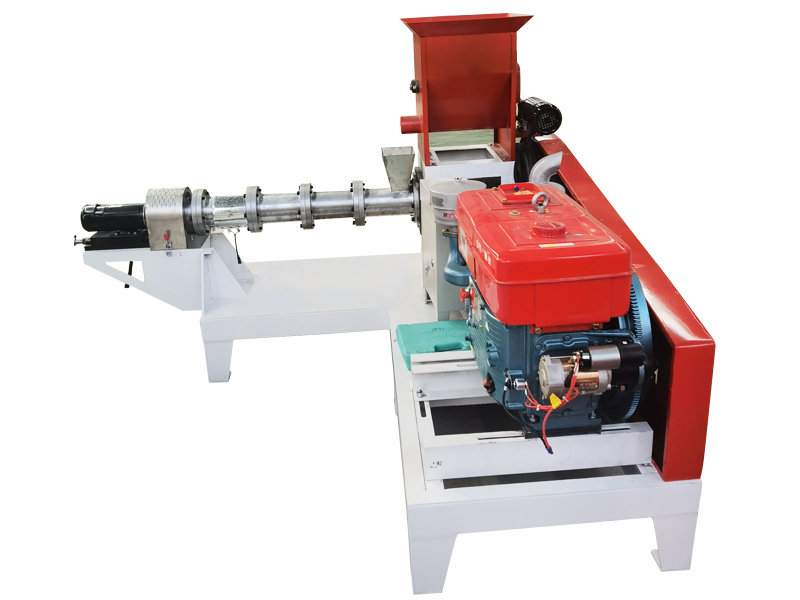

This small feed pellet mills can produce kinds of pellets for pig/chicken/sheep/cattle feed. contact with supplier, whatapp: +86-13683823082; Email: zzwoodst

For pig feed pellets making, the screen sieve diameter of feed hammer mill is less than 1mm, while for weaned piglet is only 0.3mm. Raw materials mixing. Mixing is an essential operation for the whole pig feed pellets production line. Grounded raw materials should mix evenly before sent to be pressed. Pig feed pellets pressing.

China Pig Pellet Machine - Select 2021 Pig Pellet Machine products from verified China Pig Pellet Machine manufacturers, suppliers on LimaFeedPelletizer.com.

As the core unit offish pellet mill, rolls and dies are all made of high alloy metal to ensure a low consumption. 5. Pellets size is from 2-12 mm upon your requirement. When making different size, you just need to change the die mould. AZSP150D biopellet machine. AZSP200D biopellet machine. AZSP230D biopellet machine.

Aimed at the large-scale pig dung fertilizer making plants, you can use wheel type composting machine and compost turner of crawler type. Pig Waste Disposal System of Auxiliary Materials The swine poo content is about 15%, nitrogen content is about 0.5%, phosphorus content is about 0.5-0.6 % and potassium content are about 0.35-0.45%.

YUCHENGTECH Electric Animal Feed Food Pellet Machine Electric Pet Pellet Food Mell Making Machine for Making Large Dog Pig Feed 110V/60Hz (9mm for Large dog) 5.0 out of 5 stars 1 $159.00 $ 159 . 00

pig feed pellet machine: SZLH420: 1 : pig feed expansion equipment: SPZS225: 1 : Auxiliary equipment: Batching scale*PCS10/PCS05, Granular material sieve*SCY80 , Powder sieve*SQLZ60×50×100, Cooling equipment*SKLN6, Belt scale (both powder and granular feed), packing range 20-50kg/bag, 6-8 bags/min, MCC Control Center; Mimic Control Panel, etc. Complete set pig feed machine cost: 100000-300000USD

1200-1500kg/h lima feed processing line animal feeds pellet making machine cow pig chicken sheep feed pellet machines for sale Ready to Ship 1 Piece (Min. Order)

Mar 23, 2021 · Why not choose an animal feed machine to make feed pellets by yourself to save cost. You can find a pig animal feed pellet mill to reduce your cost by making your own pellet feed with such a machine using grains like corn powder, wheat, rice husk, wheat straw, vegetables, and so on. Pigs really appreciate variety in their diets.

Under the action of 100 ~ 120℃ hot steam during the pelletizing process, pig feed pellets will soon become gelatinized and generate a better taste. It is easier for pigs to digestion and absorption. Processed under high temperature, pellets is more healthy for pigs. With good liquidity, pig feed pellets also perform well in storage and