2. Choosing the Right Fish Feed Grinder Machine: The selection of the appropriate fish feed grinder is a complex decision that can significantly affect both production quality and overall costs. Factors to consider include: Capacity: Matching the grinder’s capacity to the farm’s needs helps in avoiding overcapacity or undercapacity scenarios.

.jpg)

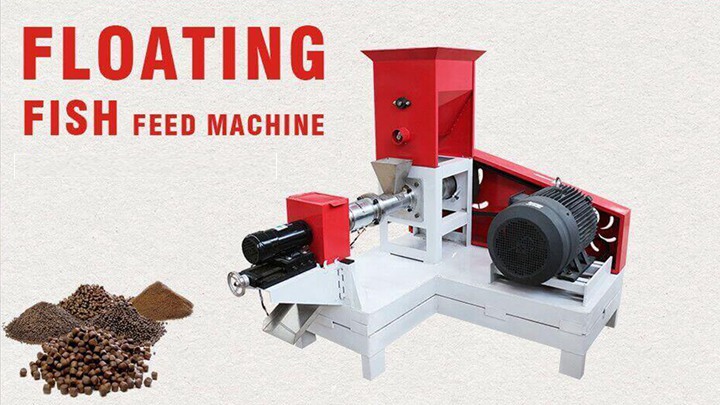

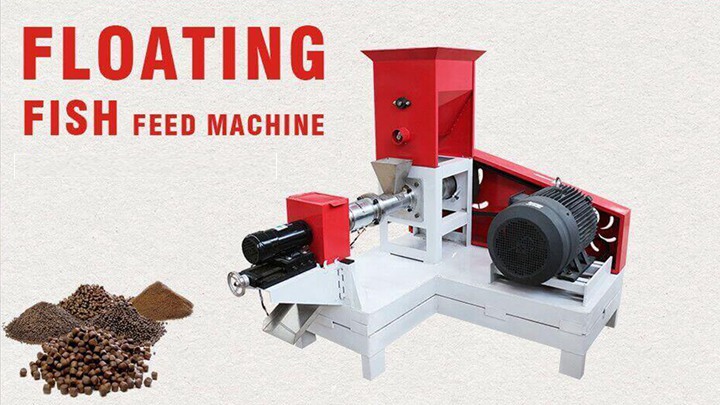

Our wet floating fish feed extruder produces 0.9-12mm pellets, suitable for pet food and animal feeds, including shrimp. We also offer a sinking feed extruder for sink pellets. The machine works with single or three-phase power. It offers capacities from 30kg/h to 5000kg/h, split between small and large scales.

.jpg)

This customer interested in SFE60C and SFE70B fish feed extruder. His demand is production capacity <250 kg/h and the pellets must float. According to customer needs, This 200kg/h fish feed making set contains: mixer machine, fish feed extruder, pellet dryer and oil sprayer. Photos: 200kg/h small fish feed making plant for Tanzania.

73% Response Rate. View Mobile Number. Contact Supplier Request a quote. Sinking Fish Feed Making Machine, 50-60 Kg Per Hr ₹ 63,000. Get Quote. Micro Fish Feed Extruder, 80-100 Kg Per Hr ₹ 2,80,000. Get Quote. Sinking And Floating Fish Feed Processing Line, 1000 Kg Per Hr ₹ 35,00,000. Get Quote.

.jpg)

RICHI 1-60 t/h floating fish feed production line is an aquatic feed processing system specially designed for extruded aqua & pet feed.

.jpg)

Prices fluctuate based on the model, capacity, and the manufacturer. On average, a floating fish feed machine price in Nigeria can hover between NGN 2 million to NGN 10 million. It’s essential to assess the initial investment concerning the floating fish feed making machine durability, efficiency, and potential after-sales services.

.jpg)

A: In India’s ever-growing aquaculture sector, employing an automatic fish feed machine offers several advantages: 1. Efficiency: Automatic fish feed making machine in India significantly speed up the feed production process compared to manual methods, allowing for more production in less time. 2.

6. Extrusion with steam preconditioning is known as the wet-type fish feed extruder. The wet-type processing needs a boiler to make steam for the conditioner and ripen the raw material in advance. Dry feed pellets are stable for relatively long periods, for convenient storage and distribution. Note: This floating fish feed machine can only work

.jpg)

Investing in a floating fish feed making machine in Philippines also has economic implications. By controlling the feed production process, you can significantly reduce the operational costs and reliance on external suppliers. This self-sufficiency allows you to dictate quality and pricing, making your aquaculture business more profitable and

.jpg)

First, let’s understand floating fish feed pellets’ advantages over sinking feeds. The extruder’s screw cooks the material at 120-175°C for about 30 seconds. This enhances digestibility, inactivates enzymes, and increases starch gelatinization. Thus, the feed breaks down slower in water, allowing fish more time to eat.

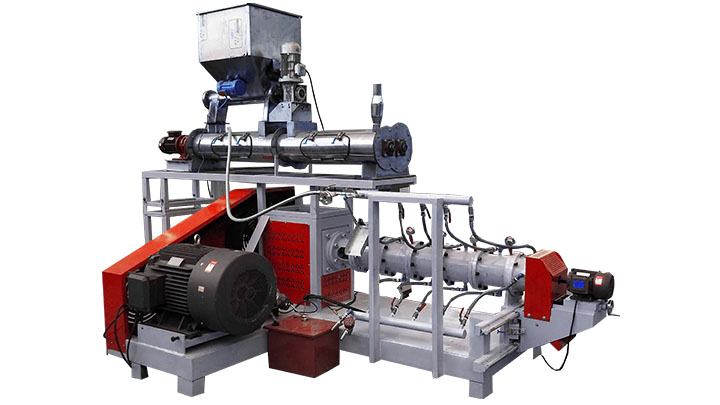

The RCPH120*2 extruder machine for fish feed is mainly used for the 1.5-2t/h production and processing of various floating aquatic feeds. The new type conditioner can soften material fibers, improve gelatinization degree, reduce power consumption and increase production capacity. Main power: 75kw.

As the professional Floating Fish Feed Pellet Machine ,our Floating Fish Feed Pellet Machine extruder machine design good manufacturing process. Brand Name:Loyal. Model Number:PFE-65-1 PFE-70-1 PFE-85-1 PFE-90-1 Place of Origin:Shandong China. Certification:CE,ISO9001,SGS,BV.

.jpg)

The initial cost of purchasing a feed pellet machine in Kenya varies significantly based on the type, features, and manufacturer. For instance, pellet machines tend to have a higher upfront cost compared to mixers due to their complexity and versatility. Always consider your production scale and specific needs to avoid overinvesting in a

The production of aquatic feed often uses a horizontal double-shaft paddle high-efficiency feed mixing machine or a double-shaft double-screw mixer. The former has a mixing time of 2 to 3 minutes and a CV of less than 5%; the latter has a mixing time of 5 to 6 minutes and a CV of 5% to 6%. . 4-5T/H floating fish feed plant often uses two mixing

Here,Lima Machinery offers a complete guide on fish feed pellet production. We can offer compact solutions for fish feed pellet production line as well as single fish feed pellet making machine. We have various types of fish feed processing machiens that can suitable small, medium and large scale fish feed processing projects!