6. Feed Formula; Low quality feeds in any market will push you out of business or may cause legal huddles for your startup, a strong formula for feeds will put a small budget for professional opinion in the setting up of the formula and employee training, Animal feed production process. To hit the market running, quality is not all you need.

The goat feed pellet making machine is flat die pellet machine that is composed of power supply, gear box, transmission shaft, die plate, press roll, hopper, cutter, hoppe, etc. Electric Control Cabinet: adopts the form of plastic spraying, with enhanced strength and toughness, and the shell will not break. Built-in safety electronic control

Mar 30, 2021 · These are primarily used in hog barns that use the puck-style conveyer to drop feed, so it is easily converted to flex augers. The cost to install this system is about $15,000. Blending boxes – Like stationary mills, blending boxes use the volumetric principle. Unlike stationary mills, they have no motorized parts.

Bagged Feeds. Our stock line of Sheep Feeds include: 16% Lamb Pellets with Bovatec (50 lb. bags) 14% Ewe/Sheep Pellets (50 lb. bags) - non-medicated. Custom bagged mixes are also available (1,000 lb. minimum order for custom mixes). Mark Hershey Farms offers bag items that can be purchased directly from our mill, or delivered to your door.

Purchase Sunrise Farms Non-GMO Custom Feed In Four Easy Ways. Custom orders require a minimum order of 1,000lbs. or 20 bags with a nominal fee. All quantities of our custom feed can be purchased directly from Sunrise Farms at our storefront, conveniently located just 3.5 miles off I-64 at exit 91. Call ahead for us to process your non-GMO

Perfectly Balanced Nutrition for Excellent Production and Efficiency. Designed for sheep receiving rations composed largely of grass and hay, Purina ® Wind and Rain ® Sheep Mineral reduces clumping and waste while supporting hoof health and reproductive efficiency. High in trace minerals and calcium, this quality product meets and exceeds nutrient requirements for high production and reduces the risk of milk fever and ketosis.

Jul 06, 2021 · July 6, 2021. 261. Sheep at Ovino farm, Acton, Ont. await return to their bedding area after milking. (Andrew Coppolino/CBC) Ovino is hoping that the demand for sheep-milk products continues to increase, and with their state-of-the-art facility near Acton, Ontario, able to accommodate 2,000 sheep, they’re ready to meet that demand.

May 25, 2021 · There are almost 300.00 million bovines, 135.2 million goats, 65.07 million sheep, List of approvals required to start Feed Mill Business. For permissions, the ...

Mar 13, 2019 · Corn around here has a plant population average of about 20-25,000 per acre in 30” rows. That adds up to about 20-30 or more tons of feed per acre, as farmers figure it, chopped into the silo. That is when the plants have dried down a little, later in September. A corn plant has a great deal of moisture in it.

Sheep & Goat Feed. MFM manufactures quality feeds for your sheep or goats by using only the highest quality ingredients and providing protein, energy, minerals and vitamins to meet your animal’s requirements. If you are a show enthusiast, breeder or have an animal as a pet we have a product that will meet your needs. To find Martindale Feeds

Aug 07, 2020 · Feed milling business is a growth enterprise in Nigeria. The Country feed mills produce feed for mostly poultry (chicken, turkey, ducks, guinea fouls, and quails, among other birds). Other classes

Roughage refers to all kinds of forage, hay, crop straw and silage, generally accounts for 40%~90% of total dry matter intake. For animals with low productivity such as the breeding period beef cattle and cows, empty dairy cows and non-breeding adult cattle (sheep), they can be fed roughage. The concentrate feed of ruminants differs from that

Apr 08, 2018 · Sheep Feeding for 3 Months to 1 Year of Age: It is recommended to graze the pasture at least 6 to 8 hours daily. Provide concentrate mixture (Supplemental feed) @ 100 – 200 grams/sheep/day with protein of 18 to 20%. Provide dry fodder during night times in summer and rainy days.

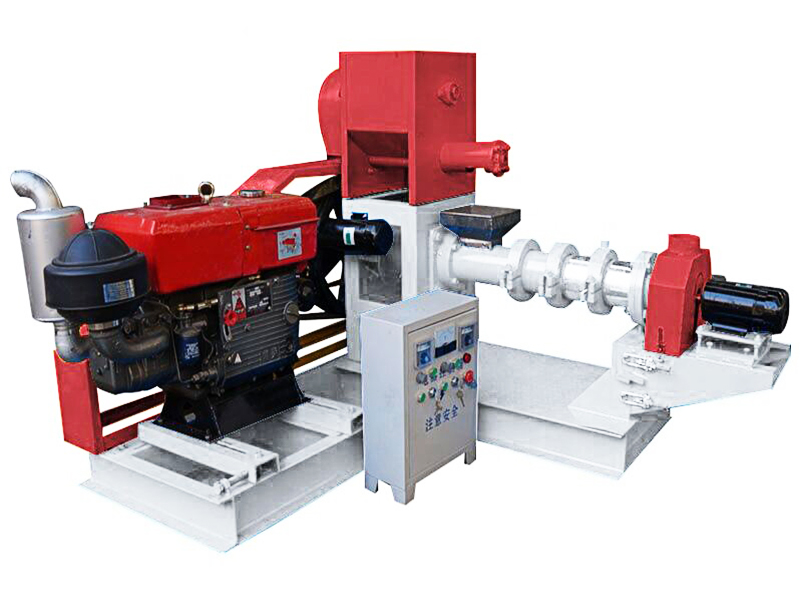

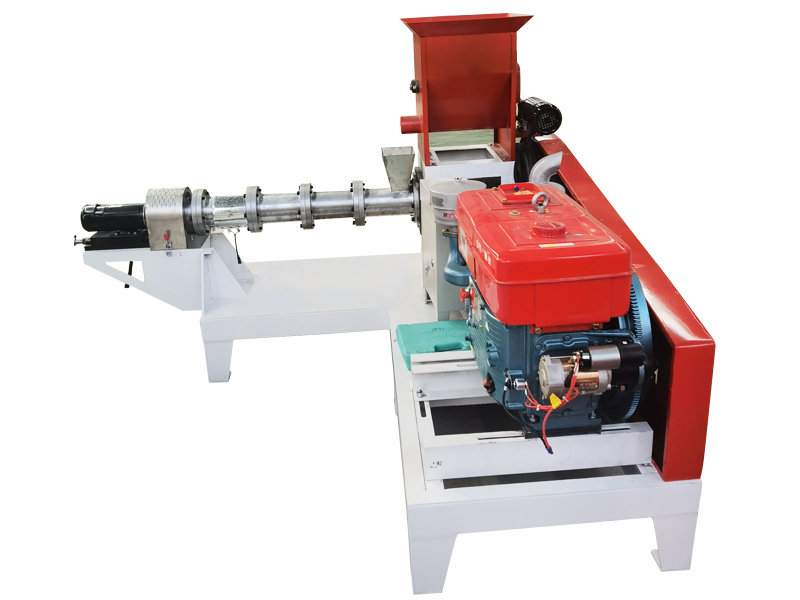

Feed Pellet Mill. The material enters the pelletizing stage after the initial cleaning, crushing and mixing. In the mini or small scale pellet mill, flat die pellet machine is the core equipment. Feed Pellet Cooler. The temperature of pellet pressed by pellet mill machine is 75-95℃, and the moisture content is 13-15%.

Feed pellet mill for sheep is a simple 6 step process: Step 1 is the grinding process by which the feed crushing machinery creates a powder from all sheep feed raw materials . Step 2 is the when the feed mixer then mixes the powder with sheep feed, thereby creating the feeding mixture. Step 3 is the feed pelleting process, through which the mixture is then ripened to create high-quality feeding pellets for sheep.