Complete sheep feed granulation production line used corn, wheat bran, soyban meal, Yeast powder for feed, Alfalfa powder, Hay, Skim milk powder, Calcium Phosphate, Salt, etc. and other essential micro-ingredients to produce feed pellet. The pellets are very nutritional and can satisfy the growth needs of sheep in different growth stages.

High quality Sheep Feed Pellet Production Line factory from China, China's leading Sheep Feed Pellet Production Line product market, With strict quality control Feed Pellet Production Line factories, Producing high quality Feed Pellet Production Line products.

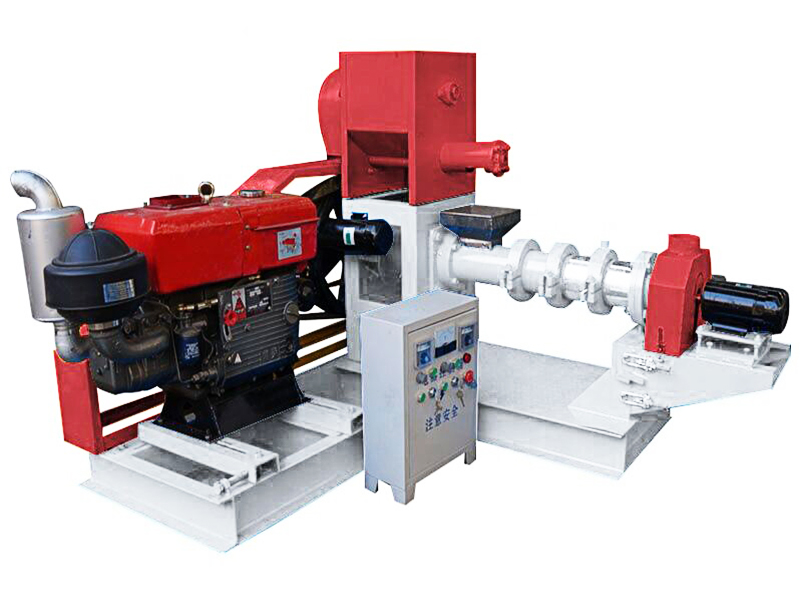

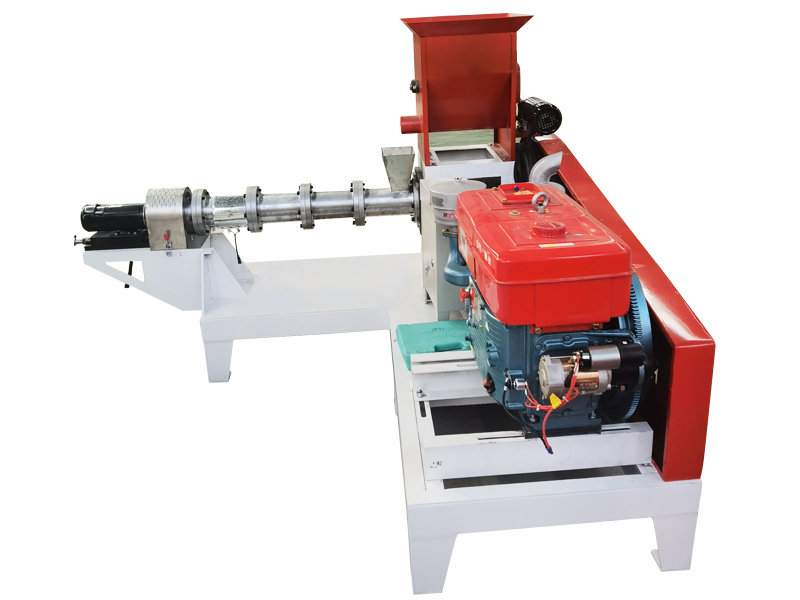

APPLICATION: Feed Pellet Production Line. CAPACITY: 100-150KG/H. MAIN POWER: 14.5KW. MODEL: RI500+FDF150B. WhatsApp: +86 138 3838 9622. Email: enquiry@pellet-richi.com. Small feed pellet line has a way to grinder, mixer, convey, pelletizer, cooler in one means, which can grind the maize and bean pulp by the grinding machine, then mix with the

The feed pellets are widely used in small-sized farms and large-medium feed factories. Herm machinery top quality sheep feed granulation production line includes grain hammer mills, conveyors, mixers, sheep feed pellet mill maker, coolers, crumbling machine, screening machine, automatic packing machine, etc.

May 29, 2022 · Note: There are two high-end poultry and livestock feed production lines, one high-end ruminant feed production line, and the process flow of the three animal feed pelleting lines is the same. Raw materials preparation. The animal feeds raw materials required for animal feed factory production are divided into powdery and granular raw materials.

AB Pedro® Sheep Farms, LLC is a licensed sheep farming business that is committed to producing meat and products such as milk and wool and even the horns and hoofs of sheep. We are in this line of business to make profits and we will ensure that we do all that is permitted by the law to achieve our business aim and objectives.

APPLICATION: Sheep Feed Industry. SIZE: 6-12mm. WhatsApp: +86 138 3838 9622. Email: enquiry@pellet-richi.com. RICHi offers turn-key project about 1-100TPH complete sheep feed pellet production line, according to the requirement, different output configuration can be customized and provides more value added service to customers.

small feed production line making poultry feed with small 2022/05/11 · Feed pellet line which can produce 3000-10000 T powder materials or feed pellets per year. The complete pell Tel:8619337889051

the third procedure of sheep manure organic fertilizer production line: you can choose to use the trunk-type stacking machine or the crawler stacking machine.pile the mixed materials in a fermenting pond or fermenting tank with a width of 2 to 6 meters and a height of 1.0 to 1.5 meters, and turn and toss them repeatedly with a stacker every other

sheep feed production line manufacturers Complete Sheep Feed Pellet Production Line Solution. Determine the scale of sheep feed mill. Determine the feed... Sheep feed pellet production line Manufacturers & Suppliers. sheep feed pellet production line for sale, sheep feed pellet. It is a feed ...

The major operations involved in the sheep feed production lines are: raw materials preparation, primary crushing, molasses mixing, fine crushing, pellet making and packaging (optional). Raw and auxiliary materials are first charged into silos and tanks where they are made ready for further processing.

Jun 22, 2020 · Sheep farming is a very lucrative business to start. Sheep farming business involves breeding, raising sheep and selling wool, lamb and mutton. A sheep farming business can thrive in various environments. This is because sheep are a hardy flock that adapts easily to varied conditions and are generally easy to handle.

the third procedure of sheep manure organic fertilizer production line: you can choose to use the trunk-type stacking machine or the crawler stacking machine.pile the mixed materials in a fermenting pond or fermenting tank with a width of 2 to 6 meters and a height of 1.0 to 1.5 meters, and turn and toss them repeatedly with a stacker every other

1. Determine the scale of sheep feed mill. 2. Determine the feed process and recommend sheep feed machine. 3. Control mode selection. 4. Sheep feed manufacturing plant structure selection. 5. Planning the general drawing of sheep feed mill plant site. 6. We devote ourselves to undertaking all sheep feed production line 1-20T/H.