.jpg)

Advanced pelleting systems are capable of delivering durable, water-stable particles that increase feed efficiency. Pelleting also increases nutrient digestibility and reduces microbiological activity. Many of these advantages are the result of heat treatment of ingredients, followed by pressing the mix into discrete particles. Treating feeds with See full list on globalseafood.org The improved handling and performance of feeds brought about by additional processing also led to the application of extrusion in the feed industry. Low-moisture and dry extrusions have been utilized for many years. Although their applications are usually limited to the extrusion of dietary ingredients such as full-fat soy, extrusion of complete di... See full list on globalseafood.org The similarities between dry extruders and expanders are striking, and close examination of the principles involved and effects on final products reveal only subtle differences. Expanders are usually quoted at much higher capacities than dry extruders. This is made possible by putting less energy into the product per unit of throughput. This fact i... See full list on globalseafood.org Early extrusion systems focused mainly on production of floating feeds, but more advanced systems are capable of delivering a complete range of expansion control. The greater process flexibility for extrusion as outlined in Table 4 is primarily due to the ability to impart more energy into the product. See full list on globalseafood.org This increased flexibility is reflected in higher processing costs, as extrusion will generally require more than double the cost inputs per ton compared to pelleting. In compensation for this greater cost, extrusion offers the capability of utilizing lower levels of starch and supplemental binders and higher levels of fat and fiber. This can subst... See full list on globalseafood.org Both pelleting and extrusion have found a niche in the manufacture of aquatic feeds. Pelleted feeds are largely confined to sinking aquatic feeds such as those for shrimp, trout, and others where the fat requirements are below 12 percent. Extrusion, on the other hand, can provide feeds for these species plus those that require higher levels of fat ... See full list on globalseafood.org

.jpg)

Apr 1, 2004 · Fig. 1: Zones of a single-screw extruder. Fig. 2: Protein molten phase and swollen starch granules. Fig. 1 is a schematic view of a single-screw extruder with different zones. The first section is the feed zone, where the formula mix is added to the extruder. This zone is characterized by deep channel screws designed to convey.

Processing and Application of Floating and Sinking Fish Feed. With the further development of the fish farming industry, extruded fish feeds have obtained more and more wide applications in virtue of unique advantages including high nutrients, good palatability, strong digestibility, and so on. As a new technology to produce feed, extrusion

.jpg)

A: In India’s ever-growing aquaculture sector, employing an automatic fish feed machine offers several advantages: 1. Efficiency: Automatic fish feed making machine in India significantly speed up the feed production process compared to manual methods, allowing for more production in less time. 2.

RCPH120*2 floating fish feed extruder machine is the third generation of new twin-screw extruder machine developed by Richi Machinery on the basis of digesting and absorbing foreign advanced technology. Its power configuration is 90KW, and the output of processing aquatic feed is 3-4 tons per hour. It can meet the current production needs of

Floating Fish Feed Extruder Machine 3-4T/H. Floating Fish Feed Pellet Making Machine 4-5T/H. Floating Fish Feed Pellet Mill 6-7T/H. Fish Feed Pellet Extruder 8-10T/H. Floating Fish Pellet Machine For Sale 10-12T/H. Sinking Fish Feed Machine. Menu Toggle. Fish Feed Processing Line. Sinking Fish Feed Pellet Mill 0.6-1.2T/H.

.jpg)

May 1, 2011 · In either case, extruders typically have a 60 to 70 percent reduction in capacity for small feed production. A standard 5- to 6-ton per hour extruder can produce 1 to 2 tons per hour of either floating or sinking small-diameter feeds or products less than 3 mm in diameter. The relationship is similar for larger-capacity extruders. How can we

Extrusion is a key process in making fish feed, especially for fish that need high energy and easy digestion. With extrusion, we can adjust the bulk density to create feeds suitable for different fish. Some fish prefer floating pellets, while others need pellets that stay stable in the water for a long time. This flexibility makes extrusion an

.jpg)

3 days ago · The physical feed quality is critical in enabling the feed to provide the desired nutrition and energy to the fish. Some of the common quality issues are feed integrity, non-uniformity of feed sizes, unable to attain the desired level of floatability (in case of floating feeds), dust creation from feeds, oil leakage, rancidity issues, and raw material quality.

.jpg)

Our wet floating fish feed extruder produces 0.9-12mm pellets, suitable for pet food and animal feeds, including shrimp. We also offer a sinking feed extruder for sink pellets. The machine works with single or three-phase power. It offers capacities from 30kg/h to 5000kg/h, split between small and large scales.

ANDRITZ offers unique, high-capacity extrusion lines for the production of all kinds of feed for fish and shell fish. The ANDRITZ extruders ensure that the feed has the right physical properties – giving it the correct sinking attributes according to where in the water the feed should be accessed. ANDRITZ single screw extruders represent

.jpg)

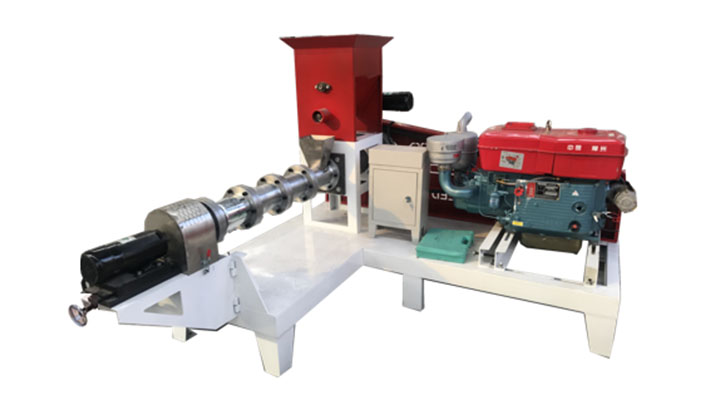

It is the ideal device for small and medium size feed processing plants and aqua-farms. DGP Series dry typefish feed extruder for floating fish feed pellet production, the pellet diameter can be varied. the fish feed pellet machine can produce many kinds of fodder for different kinds of animals.

.jpg)

Gupfenstrasse 5. Uzwil. 9240. Switzerland. Contact us. Bühler’s aqua feed production solutions include complete plant design and installation for producing a full range of fish feed pellets, including floating, sinking and slow sinking feed for shrimp, salmon, trout, seawater fish and more.

The pellet size can be from 0.9-15mm to feed different size fishes. High capacity and top quality products, Wet type Sinking and Floating Fish Feed Extruder is a preferred choice for medium or large size feed processing factory and aquaculture farm. Advantages of Floating Fish Feed Extruder. Feeding evenly and constantly: Flat-bottomed scraper