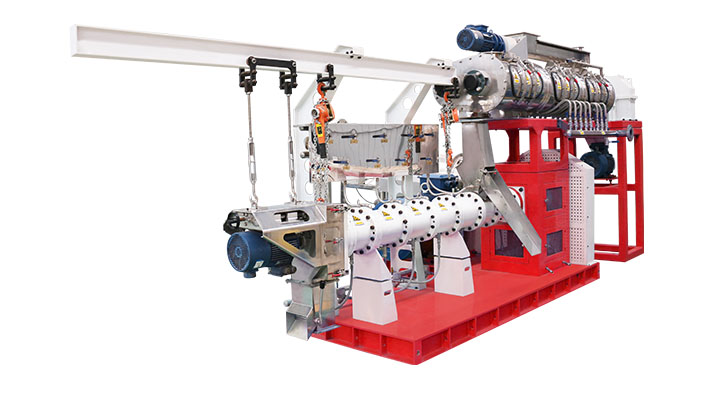

The export of the fish feed pellet extruder machine to Ghana in January 2019 was a noteworthy event for us, reinforcing our commitment to quality and customer satisfaction. The machine, with its 300kg/h production capacity and electricity power, is an answer to the growing demands of the fish farming community in Ghana.

.jpg)

The heart of any fish farming operation is a reliable fish feed pellet equipment. floating fish feed machine price in Bangladesh may vary considerably, depending on the machine’s capacity, brand, and additional features. Basic models may start from around 80,000 BDT, while more sophisticated ones can go beyond 500,000 BDT.

.jpg)

Phone. +86 19337889051. Email. lima37@limamachinery.com. Address. Socials. Lima feed machinery has been in the fish feed pellet industry for nearly ten years, focusing on the production of fish feed extruders, poultry feed pellet machines, and corresponding production lines.

.jpg)

A: In India’s ever-growing aquaculture sector, employing an automatic fish feed machine offers several advantages: 1. Efficiency: Automatic fish feed making machine in India significantly speed up the feed production process compared to manual methods, allowing for more production in less time. 2.

.jpg)

Aug 31, 2022 · floats, farm-made fish feed has to contain high-q uality binding agents (Muo et al., 2016; Nenciu et al., 2022). If the water stability of the pellets is reached, there will be less waste than in

2. Choosing the Right Fish Feed Grinder Machine: The selection of the appropriate fish feed grinder is a complex decision that can significantly affect both production quality and overall costs. Factors to consider include: Capacity: Matching the grinder’s capacity to the farm’s needs helps in avoiding overcapacity or undercapacity scenarios.

This dual-use pellet press is engineered to effortlessly handle both wet and dry materials, ensuring a streamlined and efficient approach to preparing high-quality animal feed. Key Features: 1. 2-in-1 Wet and Dry Processing: Experience the convenience of a single machine that accommodates both wet and dry feed materials.

.jpg)

Small Animal Pet Catfish Food Making Extruder Floating Fish Feed Pellet Machine: N41,000 – N67,000. Rongchang floating fish feed extruder machine: N615,000 – N700,000. Zhangsheng Fish feed making machine poultry feedfish pellet machine mill: N123,000 – N172,000. 2020 1-2TPH Chicken Cattle Cow rabbit poultry livestock fish sheep goat

Currently, floating fish feed extruder has become an ideal for small and medium fish farm (catfish, tilapia, shrimp etc.) holders or fish feed processing plant. Advantages of Dry Type Floating Fish Feed Pellet Mill 1. This fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal. 2.

.jpg)

We have the high-efficiency fish feed machine for the manufacture of various kinds of fish food pellets. 3.Easily install. A reasonable structure makes them easy to transport, install, and assemble. animal feed. 4.More choices. The machines also can be adjusted easily by changing molds. 5.Widely used.

.jpg)

3 days ago · Pellet mills are used for making sinking feeds like that for shrimp and trout. It is also utilized where the fat requirements are below 12 percent. Extrusion process can make feeds that are both sinking and floating. The ability to control the floatation of feeds makes extrusion process more versatile.

First, let’s understand floating fish feed pellets’ advantages over sinking feeds. The extruder’s screw cooks the material at 120-175°C for about 30 seconds. This enhances digestibility, inactivates enzymes, and increases starch gelatinization. Thus, the feed breaks down slower in water, allowing fish more time to eat.

.jpg)

Combining advanced Europe technology with years of practical experience, we have successfully developed different kinds of fish feed pellet machines with advanced technology and reliable performance. Model :LM40. Capacity (kg/h):30-40kg/h. Main power (kw):5.5kw. Feeder power (kw) 0.4kw.

5. Fish Feed: Feed is a recurring cost. Initially, for a small-scale farm, one might budget between ₦200,000 to ₦500,000. 6. Labor and Training: Hiring workers or undergoing training sessions may add ₦50,000 to ₦200,000, depending on the scale. 7. Miscellaneous Costs: