It can produce 1000-3000 tons mash and pellet feed per shift annually; 2. Modular Structure: The plant is compact, occupies less floor space and has low requirement on the mill tower, and Get Price

Contact us if you wish to purchase additional molds or change the size. Ideal for small-scale pellet businesses or home use. Capable of processing food crops and mixed waste material into granules at once. Electric motor driven. Die hole sizes available: 3mm, 4mm, and 5mm. Simply change the die mould to make different sizes.

small scale laying hens food machine in Ghana why-africanWhy African farmers are waking up to the huge potential of Nov 25, 2023 · In Ghana, the past few years have seen an increase in support for guinea fowl production through developmental projects such as Smallholder Agricultural Development Project (SADEP), Smallholder Rehabilitation

.jpg)

Overview of 1-2t/h simple poultry feedstuff powder feed processing unit line in Tanzania. On December 30, 2016, we signed a contract for this 1-2t/h customizable easy to use small poultry mash feed plant project with a Tanzanian customer. This is a small chicken feed production line for processing powdered feed.

.jpg)

The Tanzania customer established this small poultry feed mill plant to process powdered feed for laying hens and pellet feed for broilers, but it is mainly used to produce pellet feed. Feed Formulation: Maize, soya, soya cake, sunflower cake, wheat bran, premix, fish meal, soybean oil, bone meal.

.jpg)

Feb 05, 2019 · Vitamin/Mineral Premix 0.25kg or 250 grams. Salt 0.25Kg or 250 grams. You should add 10-20grams each of toxin binder, coccidiostat and growth enhancers like zinc bacitracin.

.jpg)

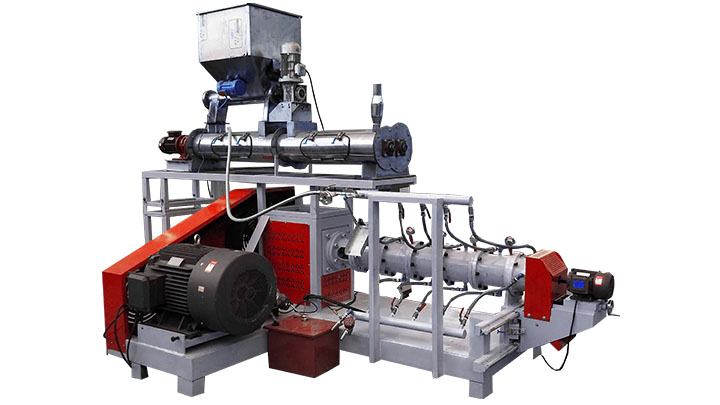

A chicken pellet making machine can be used to make pellets for cattle feed, pig feed, chicken feed, horse feed, duck feed, fish feed and even rabbit feed. The machine comes in different sizes depending on the intended feed production capacity it can be as low as 50 kg/hour to above 1 tonne/hour.

Jun 30, 2020 · Name: Advanced Small Poultry Feed Mill. Country: Nigeria. Date: June 30, 2020. Capacity: 1-2T/H. Pellet Size: 2-4mm. The install period: 20 Days. Control Mode: Automatic. Cost of poultry feed mill in Nigeria: 25000-29000USD. enquiry@pellet-richi.com.

.jpg)

Get Price & Support. 3-5T/H Malaysia Commercial Poultry Feed Mill Design. The Malaysia 3-5t/h poultry feed mill production requires a series of process and equipment. Some of poultry feed making machines may not be equipped in small scale feed mill in order to save the investment cost.

Laying hens | SchothorstSchothorst Feed Research conducts laying hen research on a small-scale and on a practical-scale. The practical-scale facility is SGS-certified in accordanc Tel : + 8619337889051

.jpg)

RICHI Machinery MZLH350 seriesfish pellet making machine has wide adaptability. According to different raw materials, different pellets can be produced. Larger feeders increase production capacity and ensure production efficiency. Power: 55KW. Capacity: 500-700KG/H. Pellet Size: 6-12mm. Request Our Latest Prices Today.

.jpg)

Industry leading 2 Year factory Warranty, Over 30 years experience, contact ELF Systems today. Pellet Mills for sale in Canada, USA & North America. Turnfish, biomass, feed, plastic, hops & hemp into pellets with ELF Pellet Making Machines.

Check the tightness of the belt frequently to prevent low output of the feed manufacturing machine, belt slippage, etc. It is normal for the poultry feed pelletizing machine to work continuously and the motor heats up to 70 degrees. To ensure the quality and output, it is better not to exceed 55% of grass powder content in the feed used in flat

.jpg)

This compact chicken feed making machine is suitable for producing animal feed, alfalfa, forage or biomass pellets. It has a strong motor capable of producing up to 200 lbs of feedp/h. This feed pellet making machine comes with one flat die able to produce pellets that are 6 mm in diameter and small enough for chicken and ducks to consume.

.jpg)

The Benefits for Poultry Farmers. Investing in the right chicken feed making machine enhances: Cost-Effectiveness: Tailored feed production reduces costs. Nutritional Quality: Customized recipes lead to healthier poultry. Production Flexibility: Cater to different poultry stages with ease.