.jpg)

Fish Feed Production: Pellet Mill Vs. ExtrusionFeb 13, 2023· Introduction. Formulated fish feeds are the most cost-effective way to provide a balanced nutrition for aquac

.jpg)

For instance, a small animal feed pellet machine for sale might be priced between $500 to $2,000, suitable for small farms or home use. In contrast, larger machines designed for mid to large-scale production might cost anywhere from $2,000 to over $10,000, with the price increasing with capacity and features.

Oct 11, 2018 · Among all these flat die feed pellet mill, AZSPLM-260B feed pellet mill is our hotsale one, as it has medium capacity 400-600kg/h. Of course, we have much small chicken feed mill, the smallest one can be 60-100kg/h.

.jpg)

features of small pellet mill. Motor drive, three-phase voltage, more convenient and more environmentally friendly. Equipped with a gearbox, it can control the feeding speed, ensure the quality of feed pellets, and prolong the service life of the pellet mill.

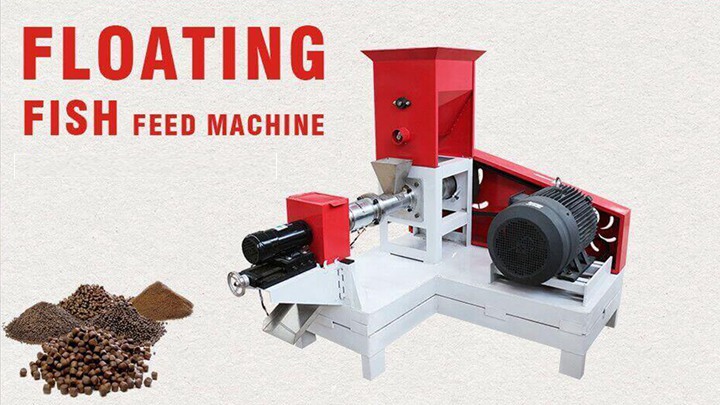

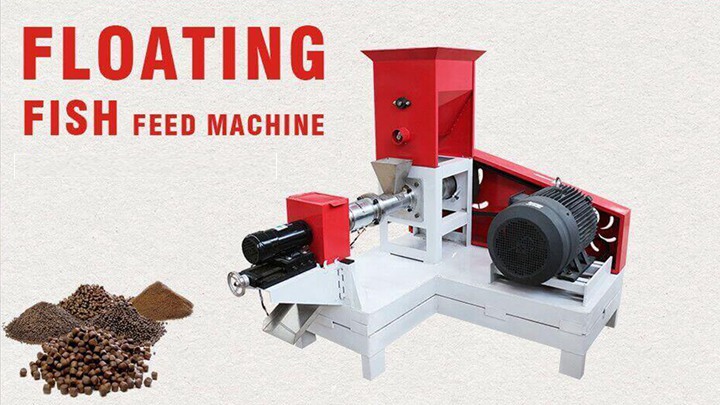

Floating fish feed production line is a complete fish feed processing line for making pellets for fish, parrots, shrimps, etc., with a capacity of 40-350kg/h.

Flat die pellet mills are suitable for small to medium-scale production and are more cost-effective, while ring die pellet mills are ideal for large-scale production due to their higher efficiency and output capacity.

.jpg)

May 3, 2024 · The key tools and materials needed for a homemadefish pellet mill include a hammer mill, pellet mill, reliable pellet mill, regular cleaning and lubrication equipment. Building the frame and constructing the pelletizing chamber require measuring and cutting lumber, securing pieces together, ensuring a square and level frame, and choosing

.jpg)

19F, Suite B, Global Trade Mansion, Wenfeng Avenue, Anyang, Henan, P.R.C. 455000 ; 0086-372-5965148; 0086-372-5951936; info@pelletequipments.com

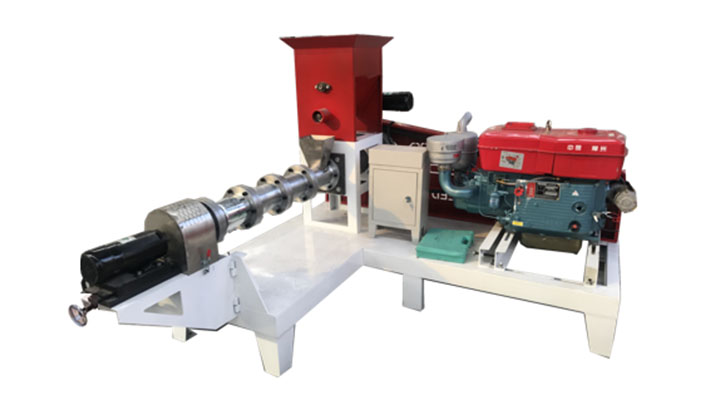

what is feed pellet mill? A animal feed pellet mill is a device that produces animal feed pellets from raw materials including grains, grasses, straw, and other plant-based products such as corn, wheat bran, rice husks, soybeans, and other similar ingredients. it can use the power source of electricity or diesel The pelletizing process includes crushing, mixing and pressing the raw materials

.jpg)

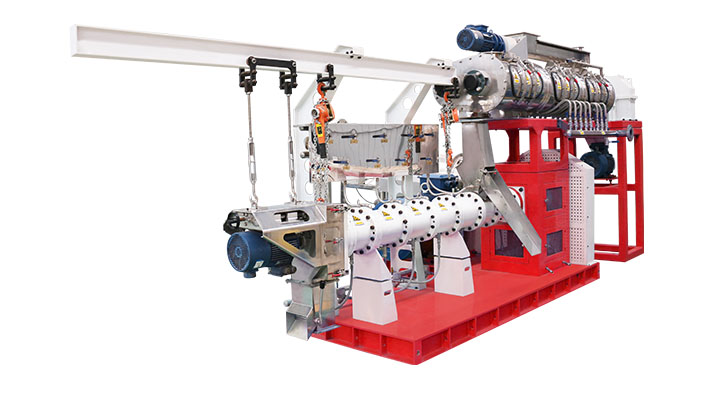

Our pellet mills, equipment, process expertise and professional support can help you to create the perfect pellets for your specific application. Our range caters for a vast range of sizes and capacities for aqua feed, pet food, grain processing and by-product pelleting processes.

.jpg)

Small Scale Fish Feed Pellet Making Machines at Factory Price. Raw Material Preparation. The first step is to gather the necessary ingredients for the feed formulation. Common ingredients for fish feed pellet making include fishmeal, soybean meal, wheat flour, fish oil, vitamins, and minerals.

Hammer mill: This is the most common method of grindingfish. Thefish is placed in a hammer mill and ground into small pieces. Knife mill: This is similar to a hammer mill but uses knives instead of hammers to grind thefish. Pellet mill: Some pellet mills have a grinding function built-in. Thefish is ground as it is fed into the pellet mill.

Choose the right pellet mill for you. Learn more about our brand-new innovative Pellet Mill, now available in 4 sizes. Make pellets out of a wide range of materials using our industrial-grade pellet making systems.

May 3, 2024 · Pellet mill: A reliable pellet mill is the heart of the operation, responsible for compressing thefish fibers into pellets. Hammer mill: This equipment is used to reduce the size of the raw materials, making them suitable for the pellet mill.

Please note:. Our systems are small but industrial quality machines due to this all our systems require 3 phase power (because of motor size/service factor and torque ratios required to pelletize).