Key Features to Look For. When choosing the right fish feed pellet machine, consider the machine’s efficiency, reliability, and durability. An efficient machine will consume less energy and produce more pellets per hour, which can significantly reduce your costs in the long run. Next, a reliable machine will have fewer breakdowns and require

Feed mill process steps. The feed mill receives rejected fruit from the grading tables in the reception area and waste material from juice processing. This combined material, with moisture content of about 80%, is taken by screw conveyors to the wet peel bins of the feed mill. Hammer mills then break it down into small pieces.

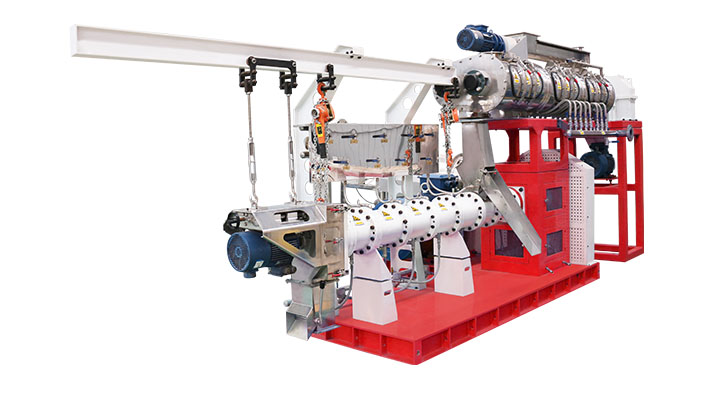

The whole Fish Feed Production Process can be highly automatically controlled. Production capacity 0.06 to 5 ton per hour is available. Feed grinder→Feed mixer→wet type Fish feed extruder→Pellets dryer→Automatic weighing and packing machine.

.jpg)

Wet type fish feed production plant is designed for Commercial Scale fish feed pellets manufacturing, large scale fish farms, with high floating fish feed production capacity.

The counter-flow cooler has the advantages of small air volume, high degree of automation, small footprint, low energy consumption when processing floating fish feed particles. Pellet Packing—electronic Packing Machine

.jpg)

6t/h manual dry mortar production line The workshop-type dry mortar mixing equipment developed by SOUTH is used 0.5 6t/h aquafeed feed machine/ feed mill/fish feed pellet mill; manual slide gate; ltd. gold member audited supplier jiangsu, china iso 9001, iso 14001, qc 080000 dry mortar line. ce 5 6t/h cattle feed production line

(PDF) A study on fish feed manufacture with its 2022 - 03 - 17 In this study, those feed mills production capacity was 45000 ton/yr Saudi-Bangla fish feed mill, 45000 ton/yr Sunny fish feed mill, 35000 ton/yr Shushomo

.jpg)

BEST Fish Feed Pellet Machine for Floating and Sinking Aquatic FeedWe are fish feed pellet machine manufacturer that help small, medium and large-scale fish pellet production clien +8619337889075 lima38@limamachinery.com

.jpg)

used for animal feed. The poor performance of the Engleberg mill has led some governments to discourage its use and in many Asian countries, the Engleberg mills can no longer be licensed to operate as service or commercial mills. 3.2 Two Stage Milling Compact Mill Two stage mills are often called compact rice mills and in many

Build advanced floating and sinking feed pellet production line with limited budget. floating fish feed pellet mill plant for small scale aquatic feed production ... with high speed, spraying atomized oil on both surfaces of the fish feed pellets.

.jpg)

The formulation of sinking fish feed plays a vital role in the health and growth of the fish. Organic ingredients and the right Fish Feed Pellet Size contribute to the feed’s efficiency.The process of sinking fish feed formulation is a sophisticated and critical phase that ensures the nutritional needs of different fish species are met.

.jpg)

Can make different size from 1mm-12mm , can feed from baby fish to big fish, Can using motor and diesel according to your requested, Easy to operate and learning .We have semi-automatic and automatic from 50kg/h-8T/h output for your choice.

A small fish feed plant is a specialized facility dedicated to producing high quality feed for fish. Think of it as a kitchen where ingredients are sourced, combined, cooked, and processed to create nutritious pellets that cater to the varied dietary needs of different fish species.

.jpg)

BEST Fish Feed Pellet Machine for Floating and Sinking We offer all kinds of fish feed pellet machines including floating fish feed pellet machine and sinking feed pellet machine. Small Pet Food & Aquatic Feed Pellet Plant (100~150kg/h) 1. Crushing Machine 2. baghouse system 3. Mixing Machine 4. Feed Extruder 5. Air Conveyor 6. Belt Dryer 7.

We offer all kinds of fish feed pellet machines including floating fish feed pellet machine and sinking feed pellet machine. Small Pet Food & Aquatic Feed Pellet Plant (100~150kg/h) 1. Crushing Machine 2. baghouse system 3. Mixing Machine 4. Feed Extruder 5. Air Conveyor 6. Belt Dryer 7. Coating Machine